Method for producing copper sulphate by using copper-containing waste solution of PCB circuit board plant

A PCB circuit board and copper sulfate technology, applied in the direction of copper sulfate, etc., can solve the problems of many impurities, large amount of waste water, instability, etc., and achieve the effect of improving product quality, reducing sulfuric acid consumption, and reducing waste water amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

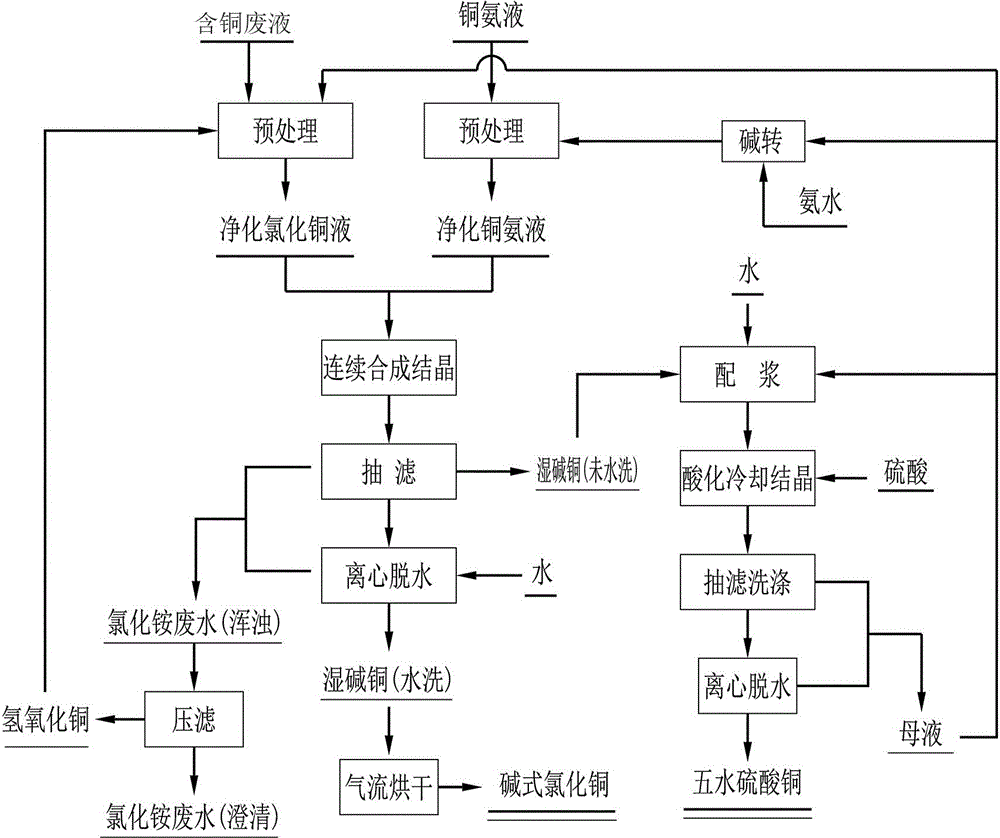

[0032] Refer to attached figure 1

[0033] The method for producing copper sulfate with the copper-containing waste liquid of PCB circuit board factory comprises the steps:

[0034] S1. Removing impurities from copper-containing waste liquid

[0035] Put 15 tons of copper-containing waste liquid with a copper ion concentration of 8% in a reaction tank for removing impurities, take 2 kg of industrial barium carbonate and 5 kg of activated carbon powder and add them to the reaction tank for removing impurities, and adjust the concentration of copper-containing waste liquid with copper ammonia or ammonia water. The pH value of the copper waste liquid, so that the pH value is in the range of 1.0 to 1.5, 5 kg of potassium permanganate solution with a concentration of about 0.2% is added, and after stirring for 1 hour, the solution in the impurity removal reaction tank is filtered through a filter press to solidify Liquid separation, so that impurities are separated in the form of...

Embodiment 2

[0047] The method for producing copper sulfate with the copper-containing waste liquid of PCB circuit board factory comprises the steps:

[0048] S1. Removing impurities from copper-containing waste liquid

[0049] Put 15 tons of copper-containing waste liquid with a copper ion concentration of 9% in a reaction tank for removing impurities, take 3kg of industrial barium carbonate and 6kg of activated carbon powder and add them to the reaction tank for removing impurities, and adjust the concentration of copper-containing waste liquid with copper ammonia or ammonia water. The pH value of the copper waste liquid, so that the pH value is in the range of 1.0 to 1.5, 6 kg of potassium permanganate solution with a concentration of about 0.3% is added, and after stirring for 1 hour, the solution in the impurity removal reaction tank is filtered through a filter press. Liquid separation, so that impurities are separated in the form of solids, and the purified copper chloride solution ...

Embodiment 3

[0061] The method for producing copper sulfate with the copper-containing waste liquid of PCB circuit board factory comprises the steps:

[0062] S1. Removing impurities from copper-containing waste liquid

[0063] Put 15 tons of copper-containing waste liquid with a copper ion concentration of 8.5% in a reaction tank for removing impurities, take 2.5 kg of industrial barium carbonate and 5.4 kg of activated carbon powder and add them to the reaction tank for removing impurities, and use copper ammonia solution or ammonia water Adjust the pH value of the copper-containing waste liquid so that the pH value is in the range of 1.0 to 1.5, add 6 kg of potassium permanganate solution with a concentration of about 0.15%, stir for 1 hour, and filter the solution in the impurity removal reaction tank through a filter press , solid-liquid separation, so that impurities are separated in the form of solids, and the purified copper chloride solution is used for standby;

[0064] S2, copp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com