Constructed wetland compound gravel bed

A constructed wetland and gravel bed technology, which is applied in water/sludge/sewage treatment, biological water/sewage treatment, chemical instruments and methods, etc. Nitrogen and phosphorus, etc., to achieve the effect of being conducive to fixing and hanging film, improving air permeability and water content, and helping growth and reproduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

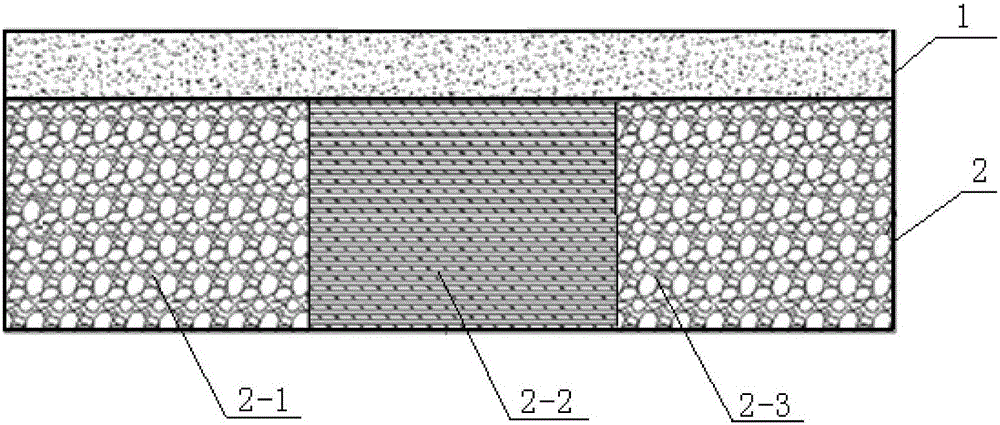

[0015] Specific embodiment one: the constructed wetland composite gravel bed of the present embodiment is made up of growth substrate layer 1 and filler layer 2, and growth substrate layer 1 is positioned at the top of filler layer 2, and growth substrate layer 1 is the mixture of soil and vermiculite, and filler layer 2 From the water inlet end to the water outlet end, it consists of gravel section 2-1, zeolite section 2-2 and volcanic rock gravel mixing section 2-3.

[0016] The constructed wetland composite gravel bed of this embodiment is divided into upper and lower layers according to the vertical direction. The growth substrate layer of the upper layer is used as the growth substrate of aquatic plants, and the filler layer of the lower layer is laid with gravel section, zeolite section, and volcanic rock in sequence from the water inlet end to the water outlet end. The gravel mixing section is used as the main body for filtering and adsorbing denitrification and phosphor...

specific Embodiment approach 2

[0017] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the growth matrix layer is uniformly mixed with soil and vermiculite according to the volume ratio of 2:(1-1.2). Others are the same as the first embodiment.

specific Embodiment approach 3

[0018] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the volcanic rock and gravel mixing section in the lower packing layer is uniformly mixed with volcanic rock and gravel in a volume ratio of 1: (1-1.2). Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com