2,2'-bipyridine, catalytic coupling synthesis method and applications thereof

A technology for bipyridine and pyridine, which is applied in the field of preparation of 2,2'-bipyridine, can solve the problems of difficulty in the source of raw material 2-halopyridine, high recovery cost of metal catalyst, complicated technological process, etc. The effect of reduced production pollution and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

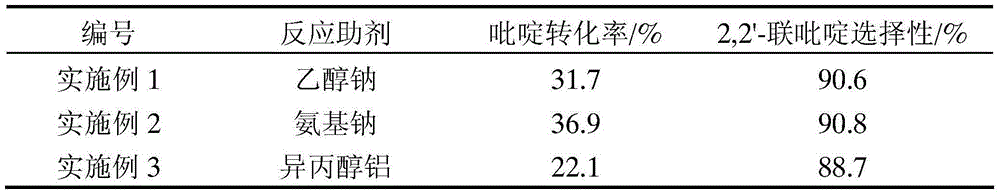

Embodiment 1-3

[0016] Weigh 522.8g DMAC, 59.3g Raney nickel, 102.1g sodium ethoxide (58.5g sodium amide or 102.1g aluminum isopropoxide) respectively at room temperature, and add 237.3g raw material pyridine into the autoclave successively. Nitrogen gas was introduced at a certain speed for a period of time to replace the air in the reactor. After the replacement, the temperature of the reactor was raised to 220°C, and the pressure inside the reactor was controlled to be 0.8-1.0 MPa. After 12 hours, the temperature was lowered and the samples were analyzed by gas chromatography. The data are shown in the table below:

[0017]

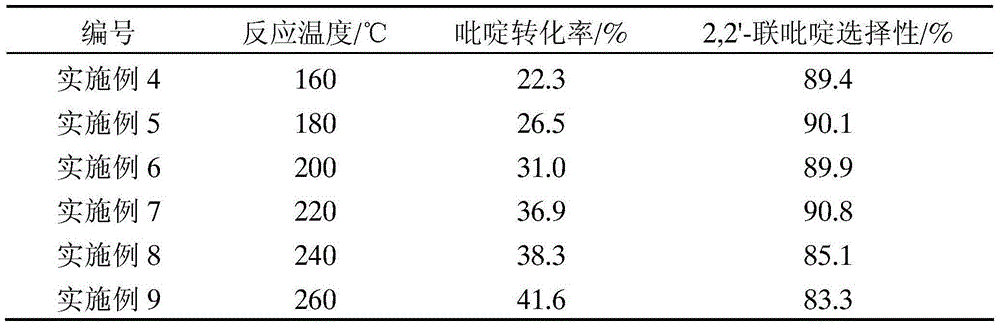

Embodiment 4-9

[0019] Weigh 522.8g DMAC, 59.3g Raney nickel, 58.5g sodium amide, and 237.3g raw material pyridine into the autoclave respectively at room temperature, and feed nitrogen into the autoclave at a rate of 100ml / min for a period of time to replace the air in the reactor . After the replacement, the temperature of the reactor was raised to 160°C, 180°C, 200°C, 220°C, 240°C, and 260°C respectively, and the pressure inside the reactor was controlled to be 0.8-1.0MPa. After 12 hours, the temperature was lowered and the samples were analyzed by gas chromatography. The data are shown below surface:

[0020]

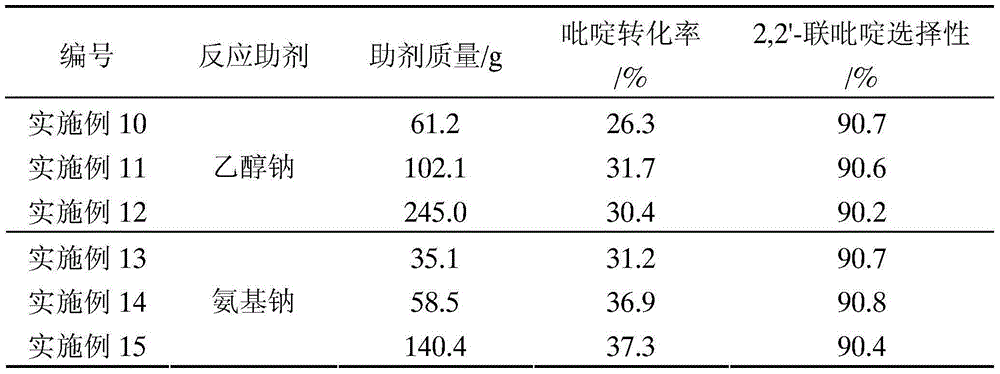

Embodiment 10-18

[0022] Take by weighing 522.8g DMAC, 59.3g Raney nickel, a certain amount of sodium ethylate (sodium amide or aluminum isopropoxide) respectively at room temperature, and add 237.3g of raw material pyridine into the autoclave successively, and pass through the autoclave at a speed of 100ml / min. Nitrogen was introduced for a period of time to replace the air in the reactor. After the replacement, the temperature of the reactor was raised to 220°C, and the pressure inside the reactor was controlled to 1.0 MPa. After 12 hours, the temperature was lowered and the samples were analyzed by gas chromatography. The data are shown in the table below:

[0023]

[0024]

[0025] From the data in the above three tables, it can be concluded that the conversion rate of pyridine raw material is increased by about 10%, and the yield of 2,2'-bipyridine is increased to more than 30%, which is completely suitable for the scale of the factory. chemical production.

[0026] The 2,2'-bipyrid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com