Purification method of streptococcus pneumoniae capsular polysaccharide

A technology of Streptococcus pneumoniae and capsular polysaccharide, applied in the field of simplified purification, can solve the problems of potential safety hazards, many steps, and high requirements for operators, and achieve large-scale amplification, avoid the use of phenol, and shorten the process time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

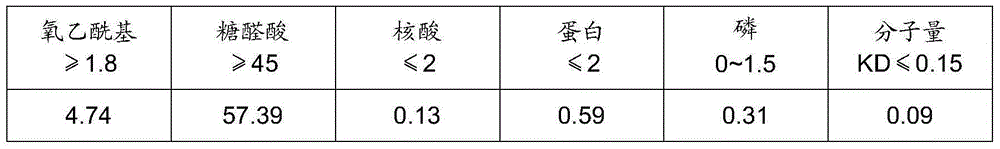

[0031] Example 1: Purification of Type 1 Streptococcus pneumoniae capsular polysaccharide

[0032] Add sodium deoxycholate to 5 L of type 1 pneumococcal fermentation culture medium to make the final concentration 0.15%, and place it at room temperature for 12 hours to lyse. Then the lysate was centrifuged (centrifugal force: 6000 g, centrifugation time: 35 minutes), and the supernatant was collected. The supernatant was then concentrated to 1000 ml by ultrafiltration in a 100 Kd membrane bag. Add sodium deoxycholate to make the final concentration 0.5%, adjust the pH to 4.4, let stand at room temperature for 10 minutes, perform centrifugation (centrifugal force: 6000g, centrifugation time: 15 minutes), and collect the supernatant. Then repeat the above steps, then add 0.5% sodium deoxycholate, adjust the pH to 4.4, let stand at room temperature for 10 minutes, perform centrifugation (centrifugal force: 6000g, centrifugation time: 15 minutes), and collect the supernatant. The...

Embodiment 2

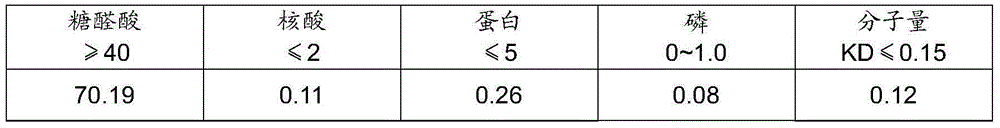

[0035] Example 2: Purification of Type 3 Streptococcus pneumoniae capsular polysaccharide

[0036]Type 3 Streptococcus pneumoniae fermentation culture medium 1L was added with sodium deoxycholate to make the final concentration 0.05%, and placed at room temperature for 15 hours to lyse. Then the lysate was centrifuged (centrifugal force: 6000g, centrifugation time: 35 minutes), and the supernatant was collected. The supernatant was then concentrated to 1000 ml by ultrafiltration in a 100 Kd membrane bag. Add sodium deoxycholate to make the final concentration 1%, adjust the pH to 4.0, let stand at room temperature for 10 minutes, perform centrifugation (centrifugal force: 6000g, centrifugation time: 15 minutes), and collect the supernatant. Then repeat the above steps, then add 1% sodium deoxycholate, adjust the pH to 4.0, let stand at room temperature for 10 minutes, centrifuge (centrifugal force: 6000g, centrifugation time: 15 minutes), and collect the supernatant. Then ad...

Embodiment 3

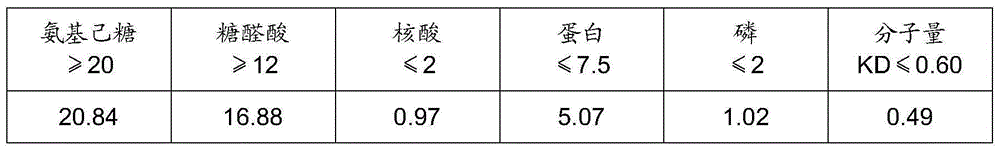

[0039] Example 3: Purification of Type 5 Streptococcus pneumoniae capsular polysaccharide

[0040] Add sodium deoxycholate to 6 L of type 5 Streptococcus pneumoniae fermentation broth to make the final concentration 0.12%, and place it at room temperature for 15 hours to lyse. Then the lysate was centrifuged (centrifugal force: 6000g, centrifugation time: 35 minutes), and the supernatant was collected. The supernatant was then concentrated to 1000 ml by ultrafiltration in a 100 Kd membrane bag. Add sodium deoxycholate to make the final concentration 0.5%, adjust the pH to 4.5, let stand at room temperature for 10 minutes, perform centrifugation (centrifugal force: 6000g, centrifugation time: 15 minutes), and collect the supernatant. Then repeat the above steps, then add 0.5% sodium deoxycholate, adjust the pH to 4.5, let stand at room temperature for 10 minutes, perform centrifugation (centrifugal force: 6000g, centrifugation time: 15 minutes), and collect the supernatant. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com