A kind of polystyrene hybrid material modified asphalt and its preparation method

A hybrid material, polystyrene technology, applied in building thermal insulation materials, building components, buildings, etc., can solve the problems of performance evaluation of modified asphalt mixture, insufficient description of road performance, lack of mixture test indicators, etc. Achieve the effect of improving high and low temperature performance, improving poor compatibility, and preventing serious aging of asphalt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

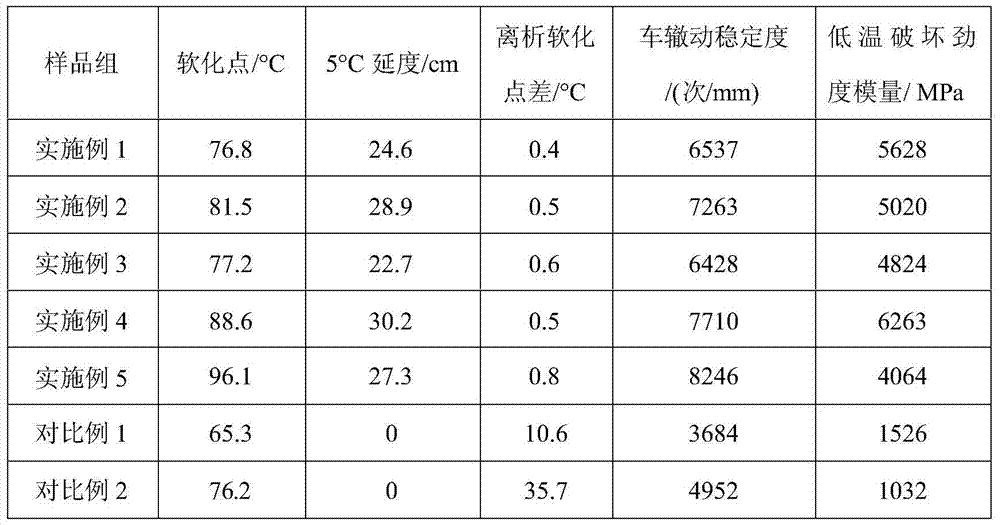

Examples

Embodiment 1

[0014] Polymerization of styrene monomer was initiated by n-butyllithium (1h, 45°C), co-hydrolyzed with tetraethyl orthosilicate (4.5h, 40°C), suction filtered and dried to obtain sample I; 15g of sample I was added to 80g In xylene, ultrasonically disperse at 25°C for 20min to obtain sample II; heat 500g of base asphalt (No. 90 heavy traffic asphalt) to 130°C, slowly add sample II, and shear and stir for 1h.

Embodiment 2

[0016] Polymerization of styrene monomer was initiated by n-butyllithium (1h, 50°C), co-hydrolyzed with ethyl orthosilicate (3.5h, 45°C), suction filtered and dried to obtain sample I; take 20g of sample I and add 150g In methanol, ultrasonically disperse at 25°C for 30 minutes to obtain sample II; heat 500g of base asphalt (No. 90 heavy traffic asphalt) to 110°C, slowly add sample II, and shear and stir for 1h.

Embodiment 3

[0018] Phenyllithium triggers the polymerization of styrene monomer (0.5h, 55°C), co-hydrolyzes with tetraethyl orthosilicate (4.5h, 45°C), suction filters and dries to obtain sample I; take 15g of sample I and add 90g In toluene, ultrasonically disperse at 25°C for 20 minutes to obtain sample II; heat 500g of base asphalt (No. 70 heavy traffic asphalt) to 120°C, slowly add sample II, and shear and stir for 1h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com