Novel metal anti-rust wax

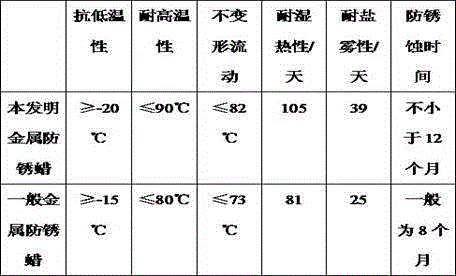

A new type of metal anti-rust technology, applied in wax coatings, anti-corrosion coatings, coatings, etc., can solve the problems of large direct economic losses, loss of use value, easy corrosion of parts, etc., and achieve good salt spray resistance and low manufacturing cost. Low, the effect of prolonging the working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] A new type of metal antirust wax, made of the following components by weight, 41 parts of paraffin wax, 15 parts of oxidized paraffin wax, 3 parts of epoxy resin, 4 parts of sodium stearate, 1 part of spar, 1.5 parts of polyglycerol fatty acid , 2 parts of acrylic acid, 1.5 parts of stearic acid, 2 parts of sodium sulfite, 3 parts of polymethyltriethoxysilane, 2 parts of polyvinyl alcohol, 1 part of 15% sodium hydroxide solution; it is made by the following production steps:

[0014] 1) Weigh 41 parts of paraffin wax, 15 parts of oxidized paraffin wax, 3 parts of epoxy resin, 4 parts of sodium stearate, 1 part of spar, 1.5 parts of polyglycerol fatty acid, 2 parts of acrylic acid, and 1.5 parts of stearic acid according to the corresponding weight parts , 2 parts of sodium sulfite, 3 parts of polymethyltriethoxysilane, 2 parts of polyvinyl alcohol, 1 part of 15% sodium hydroxide solution;

[0015] 2) Mix paraffin wax, oxidized paraffin wax, stearic acid, span and polygl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com