Method for controlling the density of sic nanoarrays

A nano-array and density technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of restricting the growth direction of products, expensive carbon nanotubes, and self-consumption, etc., and achieves easy industrial production and distribution density. and size-effective, cost-effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

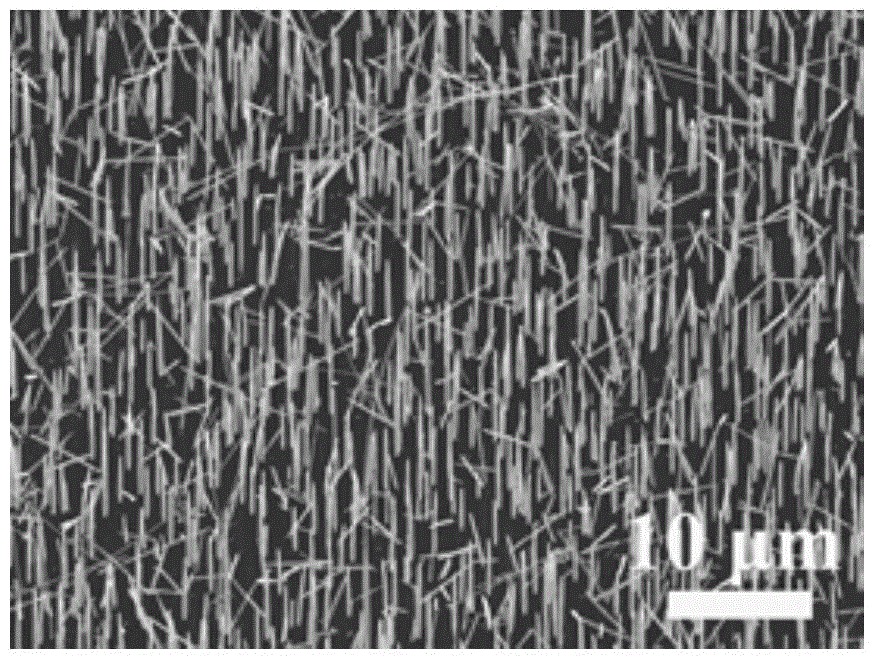

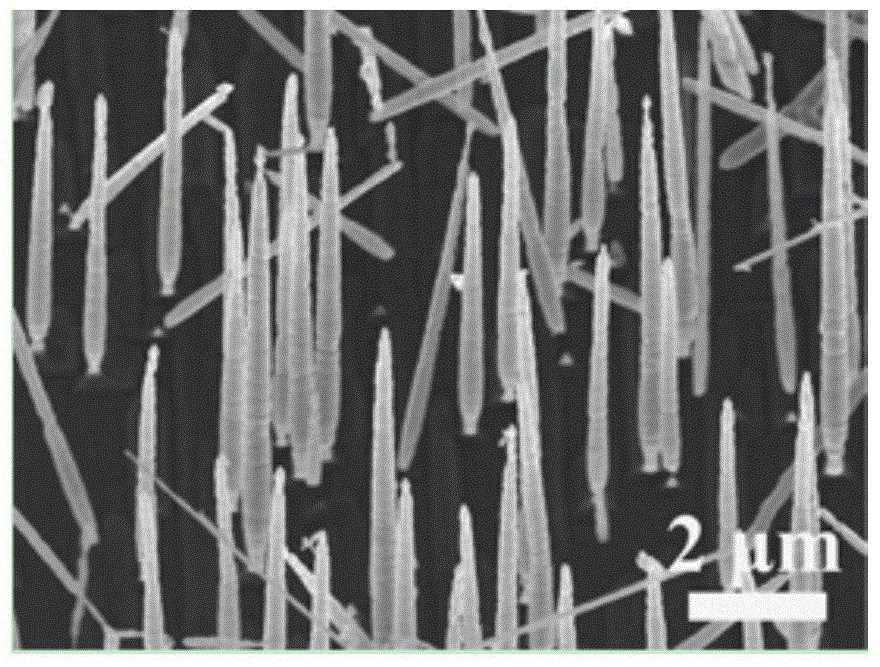

[0042] In this embodiment, the SiC nano-array includes a substrate and a nano-array formed on the surface of the substrate,

[0043] The nanoarray is an arrangement of SiC nanowires, wherein the SiC crystal form in the SiC nanowires is C type, H type or R type; the SiC nanowires are needle-like structures with a thick bottom and a thin top (SiC nanowires can also be a linear structure)

[0044] The array density of nanowires in SiC nanoarrays is (5.0-6.0)×10 7 root / cm 2 (Preferably (5.2-5.7)×10 7 root / cm 2 ).

Embodiment 2

[0046] In this embodiment, the SiC nano-array includes a substrate and a nano-array formed on the surface of the substrate. The substrate is a SiC substrate, and the lattice structure of the SiC substrate includes 3C-SiC, 2H-SiC, 4H-SiC, 6H-SiC, 15R- Any of SiC;

[0047] The nanoarray is an arrangement of SiC nanowires, wherein the SiC crystal form in the SiC nanowires is C type, H type or R type; the SiC nanowires are needle-like structures with a thick bottom and a thin top (SiC nanowires can also be a linear structure)

[0048] The array density of nanowires in SiC nanoarrays is (5.0-6.0)×10 7 root / cm 2 .

Embodiment 3

[0050] In this embodiment, the SiC nano-array includes a substrate and a nano-array formed on the surface of the substrate. The substrate is a SiC substrate, and the lattice structure of the SiC substrate includes 3C-SiC, 2H-SiC, 4H-SiC, 6H-SiC, 15R- Any of SiC;

[0051] The nano-array is an arrangement of SiC nanowires, wherein the SiC crystal type in the SiC nanowires is C-type, H-type or R-type; the SiC nanowires have a needle-like structure with a thick bottom and a thin top (SiC nanowires can also be a linear structure), When SiC crystal form in SiC nanowire is C type, SiC is 3C-SiC; when SiC crystal form in SiC nanowire is H type, SiC is any of 2H-SiC, 4H-SiC, 6H-SiC; in SiC nanowire, SiC When the crystal form is R type, SiC is 15R-SiC;

[0052] The array density of nanowires in SiC nanoarrays is (5.0-6.0)×10 7 root / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com