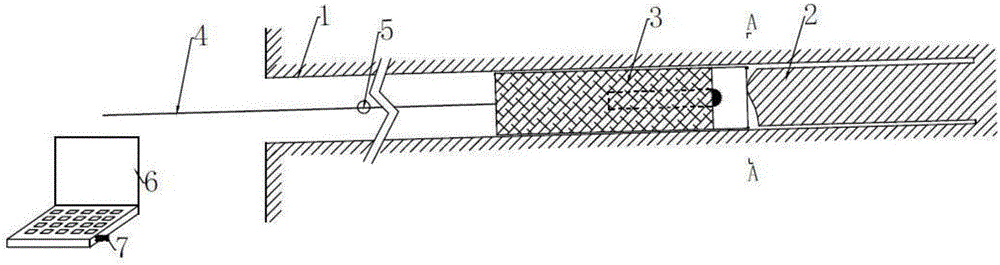

Device and method for measuring crustal stress through single drill hole

A technology of borehole measurement and in-situ stress, which is applied in earth-moving drilling, wellbore/well components, etc., can solve the problems of engineering applicability, cannot be effectively promoted, and spend a lot of energy, and achieves low cost and convenient large-scale The effect of promotion and application, the method is simple and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

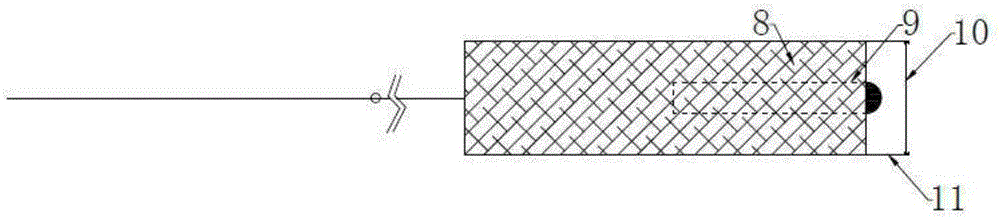

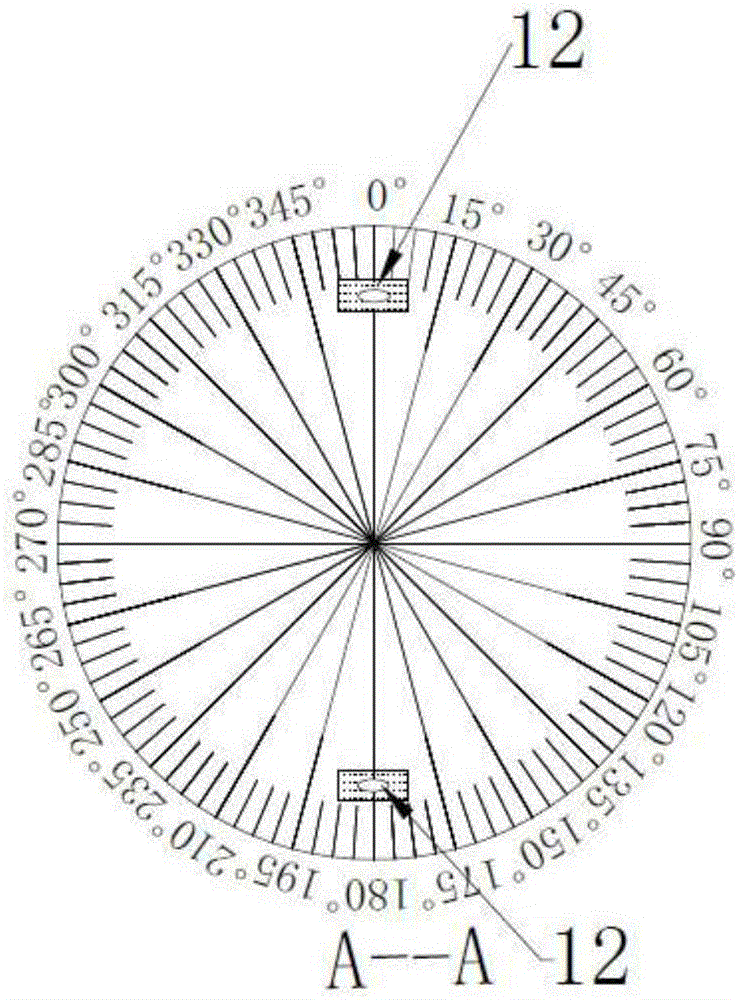

Method used

Image

Examples

Embodiment 1

[0041] The test site is the Woxi Gold Mine affiliated to Hunan Chenzhou Mining Co., Ltd. The purpose of the test is to test the magnitude and direction of the in-situ stress in the deep mining area of the Woxi Gold Mine. In order to test the feasibility and effectiveness of this method, the casing stress relief method, which is widely used in the world and has high test accuracy, is also used in the same test site for comparison and verification.

[0042] The specific implementation is as follows: first, use a horizontal prospecting rig to construct a near-horizontal borehole on the roadway wall (the elevation angle is 3-5°, which is convenient for drainage during construction), and record its azimuth and inclination angle. The diameter of the borehole is 91mm, and the length of the borehole is 5m. Above, it is required to exceed the range of the stress concentration influence zone of roadway excavation.

[0043] Later, during the drilling process, if it is found that there ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com