Realization method for synchronously reading capacitance sensors by multiple board cards

A technology of capacitive sensor and implementation method, which is applied in the direction of instruments, simulators, computer control, etc., can solve the problems of poor control precision of micro-motion stage and inability to guarantee synchronization, and achieve the effect of ensuring synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

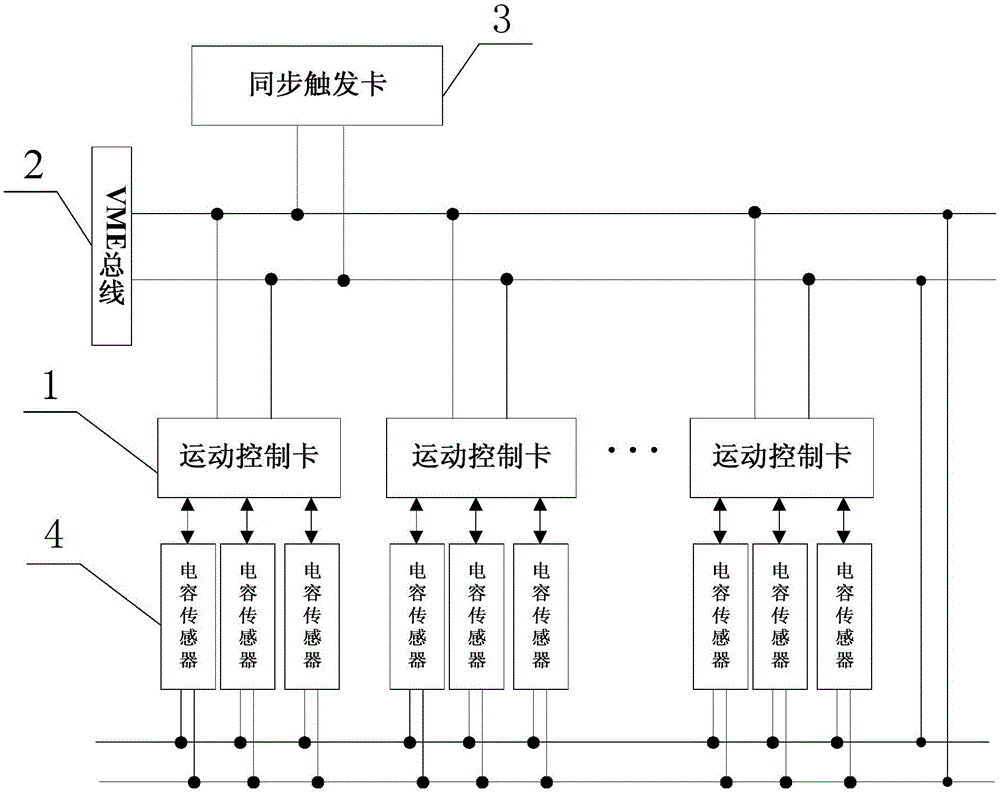

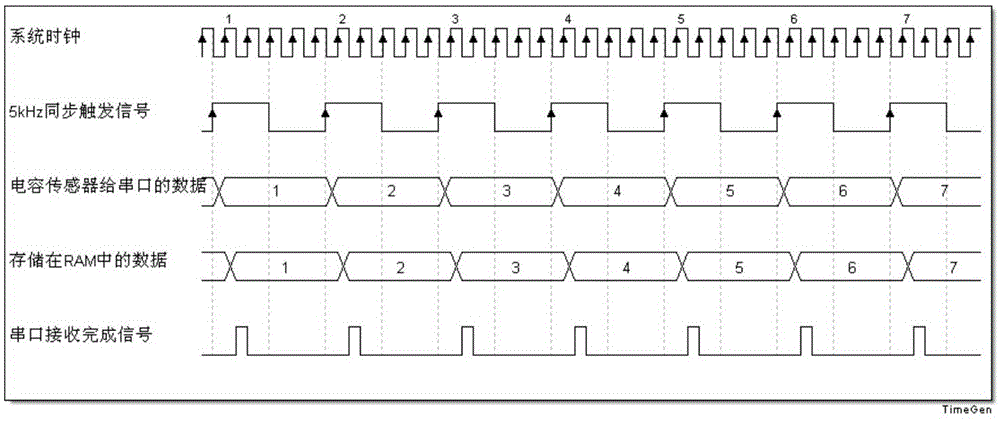

[0017] Specific implementation mode one: the following combination Figure 1 to Figure 5 Describe this embodiment, the implementation method of multi-board cards synchronously reading capacitive sensor described in this embodiment, the reading device that this method involves is: mount synchronous trigger card 3 and n block motion control cards 1 on VME bus 2, The synchronous trigger card 3 sends a synchronous trigger signal to n motion control cards 1 through the VME bus 2, and each motion control card 1 collects and stores the signals of three capacitive sensors 4 at the same time; the synchronous trigger card 3 and the motion control card 1 have the same structure ;

[0018] Motion control card 1 uses DSP module 1-1 as the algorithm processing module, FPGA module 1-2 as the main signal processing module, CPLD chip 1-3 as the level conversion module, and based on the RS422 serial port communication protocol, three Serial port 1-7 and serial port level conversion circuit 1-6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com