Rapid manufacturing method of clay model

A technology of clay model and production method, which is applied in the direction of teaching models, educational tools, instruments, etc., can solve the problems of low initial design reliability, high processing costs, and inability to carry out reverse design, so as to shorten the product design cycle and improve efficiency sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

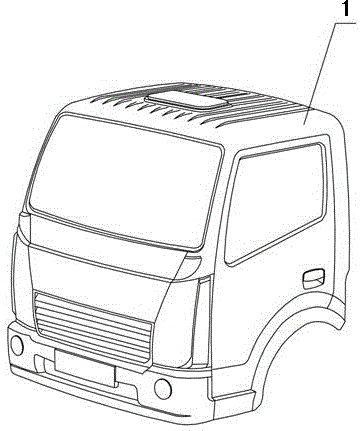

[0036] The present invention is illustrated by taking the cab of a flat-top light truck as an example, and other types of cabs can be developed with reference to this example.

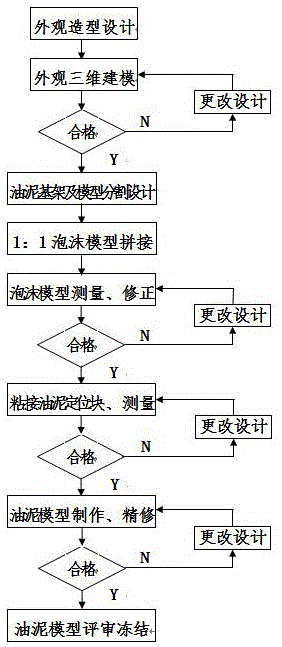

[0037] Carry out 1:1 3D modeling and design according to the appearance renderings of the cab, and draw the 3D model of the appearance figure 1 , review and modify 1 until the requirements are met;

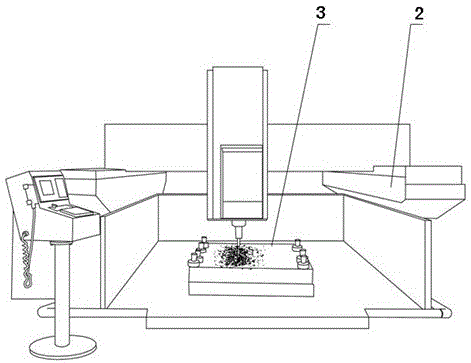

[0038] Offset the size of the outer surface of the 3D data, reserve 7mm of sludge coating allowance, design the base frame of the sludge model, divide the 3D data according to the set coordinates according to the shape of the cab, and transfer it to the foam processing machine tool 2 after programming , with a density of 90kg / m 2 The foam plate 3 is processed in blocks on the foam processing machine tool 2 according to the size of the digital model, and then the processed block model is spliced into a 1:1 foam model cab 4 based on the clay model base frame;

[0039] Fix the foam model cab 4 firmly acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com