Uniform-performance silver nanowire transparent conductive thin-film preparation method by means of dynamic infrared heating

A transparent conductive film, silver nanowire technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, can solve the problems of poor film uniformity, film non-uniformity, etc., to increase adhesion force, achieve uniform control, and reduce the effect of junction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

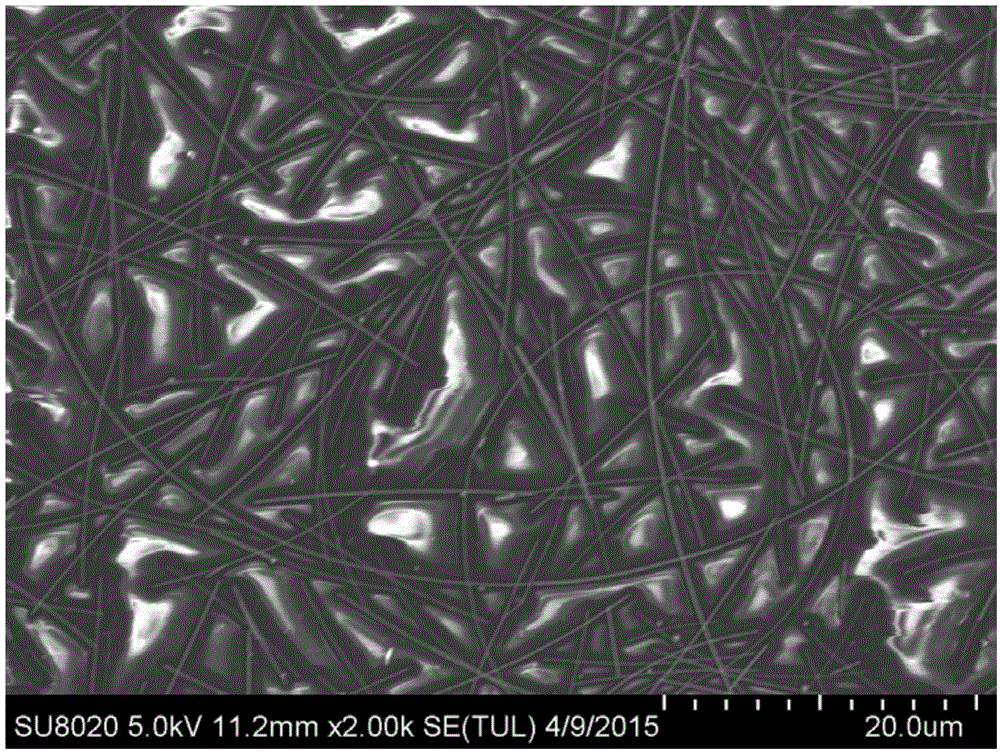

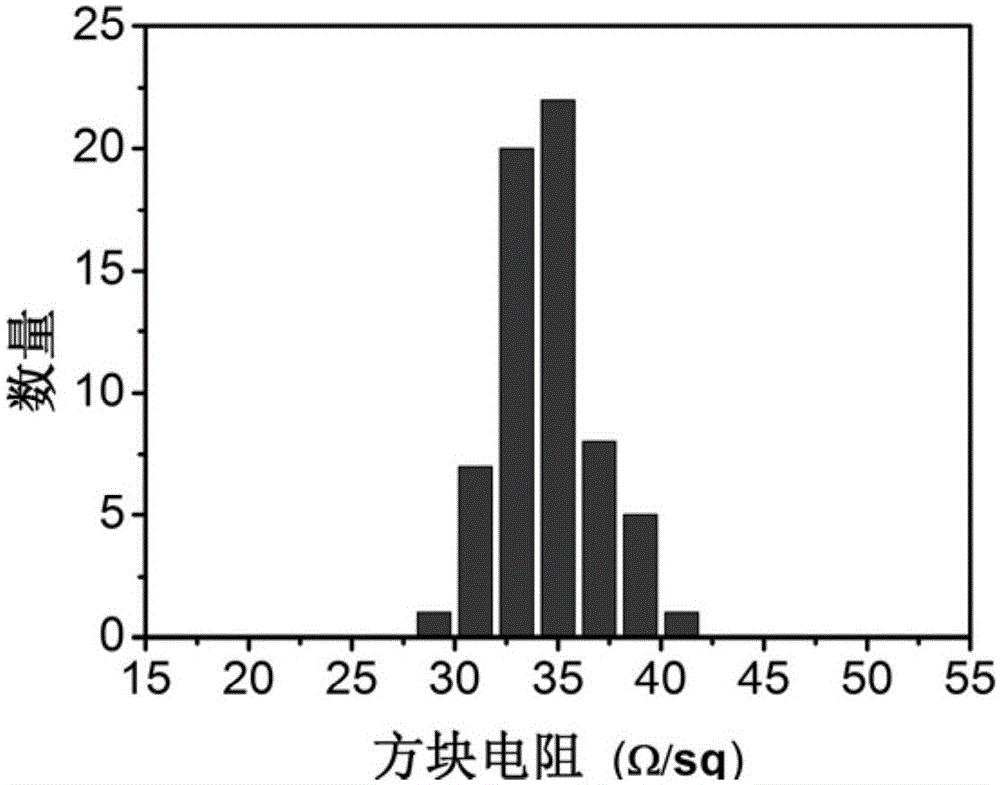

[0033] 1. Disperse silver nanowires in a solvent containing 75vol% ethanol, 12.5vol% water and 12.5vol% isopropanol. The solvent contains HPMC with a mass fraction of 0.05%, and the concentration of silver nanowires is 0.2mg / ml. Dispersion, mix it evenly;

[0034] 2. Use atmospheric pressure to fix the PET film on the glass plate and fix it with 3M tape. For the PET film with an area of 10cm*10cm, take 1ml of dispersion liquid on the PET surface each time, and use the siphon effect between the glass rod and the dispersion liquid to control the distance between the glass rods The height of the film is 0.06mm;

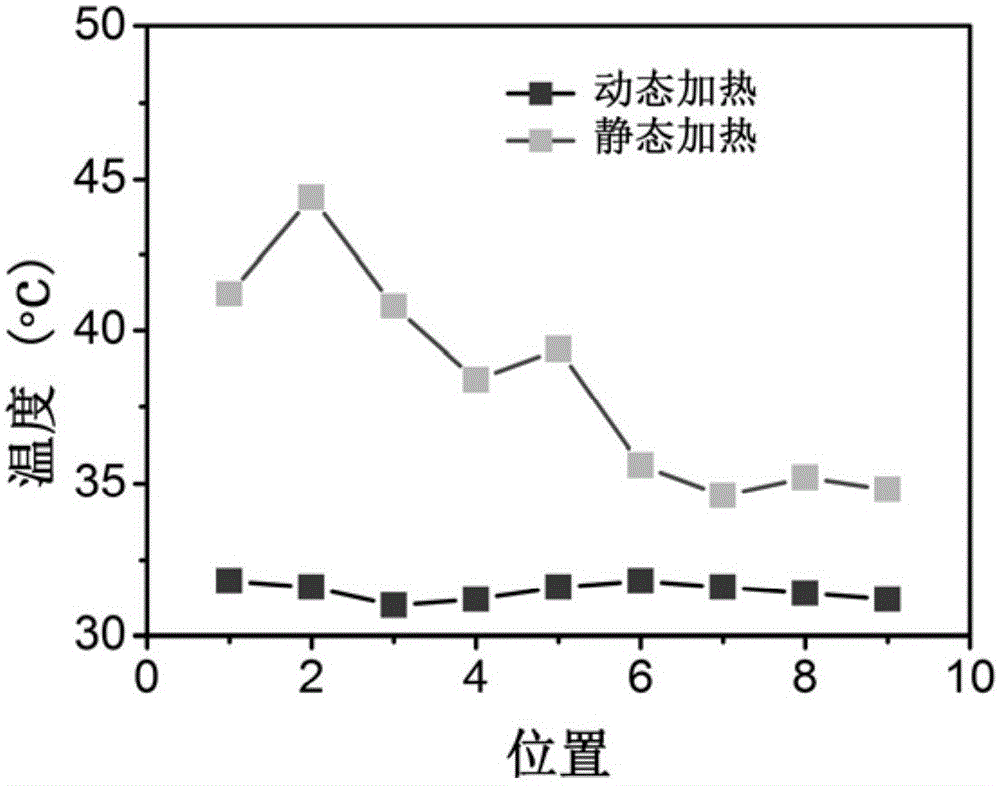

[0035] 3. Scrape the dispersion liquid dripped onto the surface of PET, scrape the dispersion liquid on the surface of the PET film in the order of first horizontal and then vertical, repeat twice, so that the dispersion liquid is evenly coated on the surface of the PET film, and scrape the liquid every time Finally, turn on the infrared heater, and then let the film ...

Embodiment example 2

[0038] 1. Disperse silver nanowires in a solvent containing 75vol% ethanol, 12.5vol% water and 12.5vol% isopropanol. The solvent contains HPMC with a mass fraction of 0.05%, and prepare a dispersion with a concentration of 0.1mg / ml. mix it well;

[0039] 2. Use atmospheric pressure to fix the PET film on the glass plate and fix it with 3M tape. For the PET film with an area of 10cm*10cm, take 1ml of dispersion liquid on the PET surface each time, and use the siphon effect between the glass rod and the dispersion liquid to control the distance between the glass rods The height of the film is 0.06mm;

[0040] 3. Scrape the dispersion liquid dripped onto the PET surface, scrape the dispersion liquid on the surface of the PET film in the order of first horizontal and then vertical, repeat 6 times, so that the dispersion liquid is evenly coated on the surface of the PET film, each time Finally, turn on the infrared heater, and then let the film pass under the heater at a speed o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| evenness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com