Thin film transistor and its manufacturing method

A technology for thin film transistors and active regions, which is applied to transistors, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve problems such as troublesome preparation processes and complex thin-film transistor structures, and achieves simple preparation methods, reduced saturation voltage, and threshold value. The effect of voltage drift reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

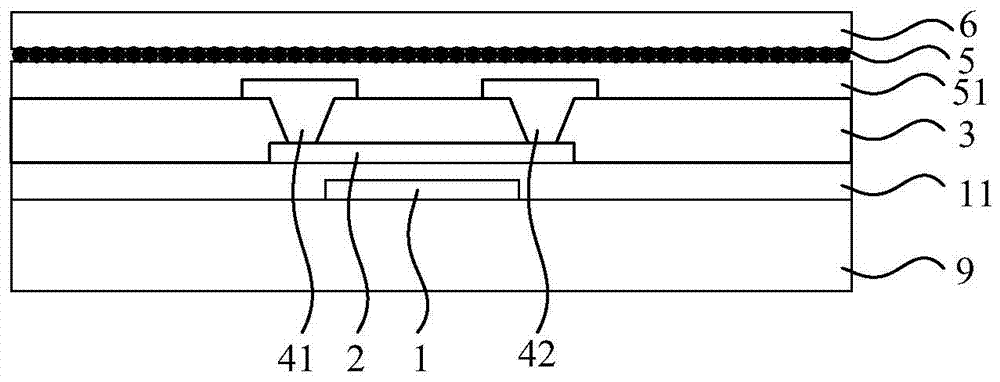

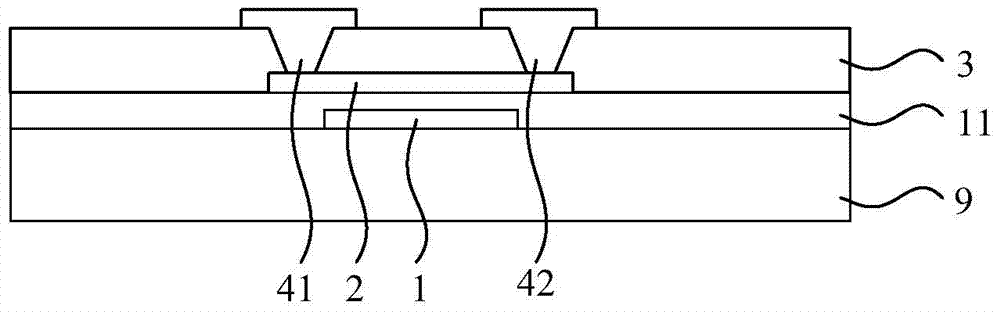

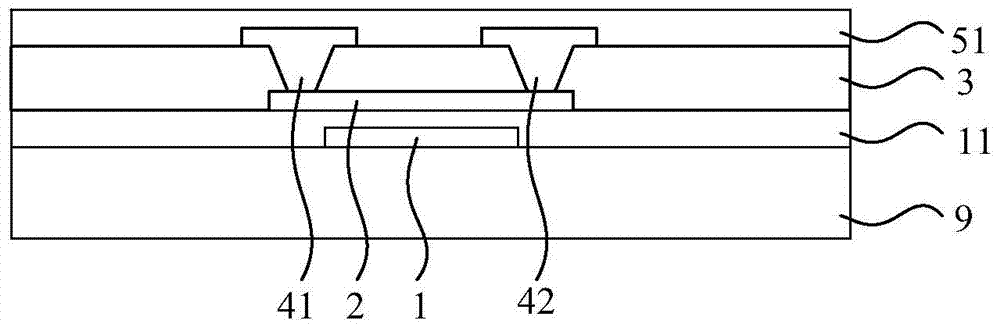

[0030] Such as Figure 1 to Figure 4 As shown, this embodiment provides a thin film transistor.

[0031] Specifically, the thin film transistor can be used in array substrates of liquid crystal display devices, organic light emitting diode display devices, and the like. Of course, it is also feasible if the thin film transistor is used for other purposes.

[0032] Specifically, the above thin film transistors include:

[0033] active zone 2;

[0034] The gate 1 and the gate insulating layer 11, the gate 1 and the gate insulating layer 11 are arranged on one of the upper and lower sides of the active region 2;

[0035] The floating gate layer 5 disposed on the other side of the upper and lower sides of the active region 2, the floating gate layer 5 includes quantum dots (preferably composed of quantum dots).

[0036] That is, if figure 1 As shown, the thin film transistor includes an active region 2 composed of a semiconductor material, preferably amorphous indium gallium ...

Embodiment 2

[0073] This embodiment provides an array substrate, which includes the above thin film transistor.

[0074] This embodiment provides a display device, which includes the above-mentioned array substrate.

[0075] Specifically, the display device can be any product or component with a display function such as a liquid crystal display panel, electronic paper, OLED panel, mobile phone, tablet computer, television, monitor, notebook computer, digital photo frame, and navigator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com