Preparation method of modified phosphatide-soybean protein composite emulsion

A technology of soybean protein and composite emulsion, which is applied in the direction of edible phospholipid composition, plant protein processing, protein food ingredients, etc., can solve the problems of insufficient emulsifying ability, poor emulsifying stability, variability, etc., and achieve high emulsifying activity and emulsifying stability Strong and enhanced emulsifying activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

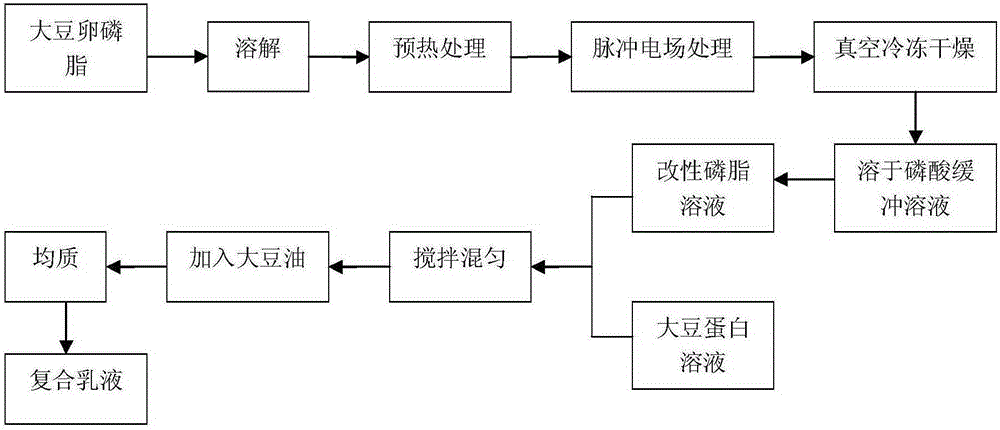

[0011] A preparation method of a modified phospholipid-soybean protein composite emulsion, the method comprising the following steps: (1) dissolving soybean lecithin in distilled water to prepare a phospholipid solution with a mass fraction of 2%, and carrying out the phospholipid solution at 80° C. After preheating for 10 minutes, pulse electric field treatment is carried out. The pulse frequency is 350 Hz, the pulse intensity is 10-30 kV / cm, and the pulse treatment time is 100-500 μs. After vacuum freeze-drying, the treated phospholipid solution is dissolved in a pH 7 in the phosphate buffer solution, magnetically stirred for 1 h to completely dissolve to obtain a modified phospholipid solution; (2) soy protein isolate was dissolved in a pH of 7 phosphate buffer solution and magnetically stirred for 1 h to completely dissolve to obtain a soybean protein solution; (3 ) After mixing the modified phospholipid solution and the soybean protein solution, magnetically stirred for 40...

Embodiment 1

[0015] Soybean lecithin was dissolved in distilled water to prepare a phospholipid solution with a mass fraction of 2%. The phospholipid solution was preheated at 80°C for 10 minutes, and the phospholipid solution was subjected to a pulse frequency of 350Hz and a pulse intensity of 25kV / cm. Pulse electric field treatment for 300 μs, vacuum freeze-dry the treated phospholipid solution, dissolve it in a phosphate buffer solution with a pH of 7, and completely dissolve it with magnetic stirring for 1 hour to obtain a modified phospholipid solution; dissolve soybean protein isolate in phosphoric acid with a pH of 7 In the buffer solution, stir magnetically for 1 hour to dissolve completely to obtain a soybean protein solution; mix the modified phospholipid solution and the soybean protein solution at a solute mass ratio of 1:10, stir magnetically for 40 minutes to obtain a mixed solution, and use the volume of the mixed solution and olive oil Olive oil was added to the mixture at a...

Embodiment 2

[0017] Soybean lecithin was dissolved in distilled water to prepare a phospholipid solution with a mass fraction of 2%. The phospholipid solution was preheated at 80°C for 10 minutes, and the phospholipid solution was subjected to a pulse frequency of 350Hz and a pulse intensity of 20kV / cm. Pulse electric field treatment for 400 μs, vacuum freeze-dry the treated phospholipid solution, dissolve it in a phosphate buffer solution with a pH of 7, and completely dissolve it with magnetic stirring for 1 hour to obtain a modified phospholipid solution; dissolve soybean protein isolate in phosphoric acid with a pH of 7 In the buffer solution, stir magnetically for 1 hour to dissolve completely to obtain a soybean protein solution; mix the modified phospholipid solution and the soybean protein solution at a solute mass ratio of 1:10, stir magnetically for 40 minutes to obtain a mixed solution, and use the volume of the mixed solution and olive oil Olive oil was added to the mixture at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com