Purslane fermentation protoplasm ceramic and preparation method and application

A technology of fermenting puree and purslane, applied in the biological field, can solve the problems of environmental damage, achieve the effects of simplifying production steps, ensuring stability, and realizing mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1, preparation purslane fermentation protoplasm

[0044] Purslane fermented puree is prepared according to the following steps:

[0045] (1) The concentration of 12mL obtained in 20mL step 3 is 10 5 ~10 8 CFU / mL fermented bacteria liquid was inoculated into 25g of purslane dry powder and 300mL of water to obtain a fermentation system;

[0046] (2) Fermenting the above fermentation system in a shaker at 38° C. for 28 hours to obtain a fermentation product;

[0047] (3) Sterilize the above-mentioned fermentation product at 115°C for 20 minutes to inactivate the bacteria to obtain the sterilized fermentation product; centrifuge the sterilized fermentation product at 4000 r / min and a centrifugal radius of 9 cm for 20 minutes, discard Precipitate and collect the supernatant, which is the fermented puree of purslane.

Embodiment 2

[0048] Embodiment 2, the application of purslane fermented protoplasm as cosmetics

[0049] 1. The properties of purslane fermented puree makeup

[0050] The fermented puree prepared in Example 1 was decolorized and deodorized by activated carbon. Its appearance is a viscous liquid, and its color is light yellow to brownish yellow. The pH value is 5.2-6.3, the viscosity is 200-500cP, the soluble solid content is 2.0-6.0%, the total number of colonies is less than 50CFU / mL, and no pathogenic bacteria are detected. According to the hygienic standard GB7916-87 for cosmetics, the total number of bacteria in cosmetics is not higher than 1000CFU / ml, so this fermented puree meets the quality requirements of cosmetics.

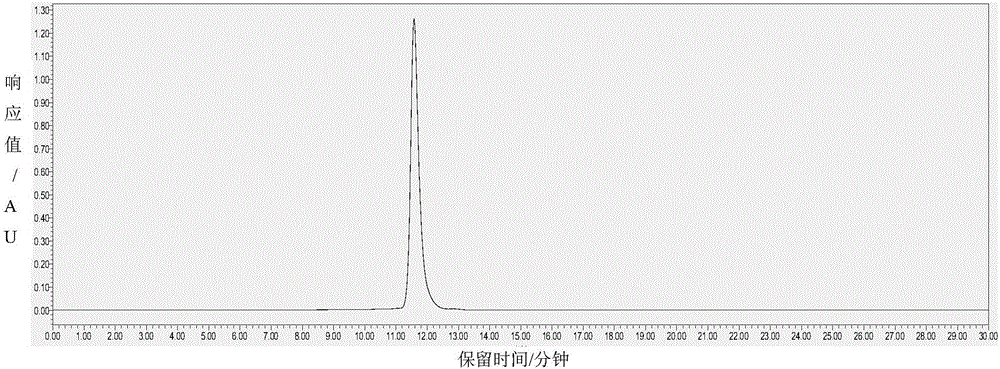

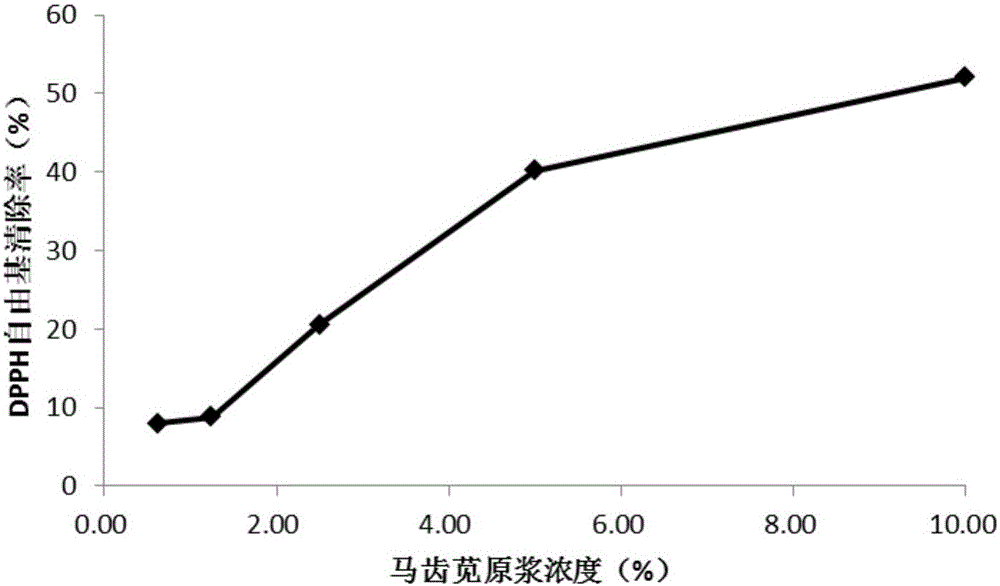

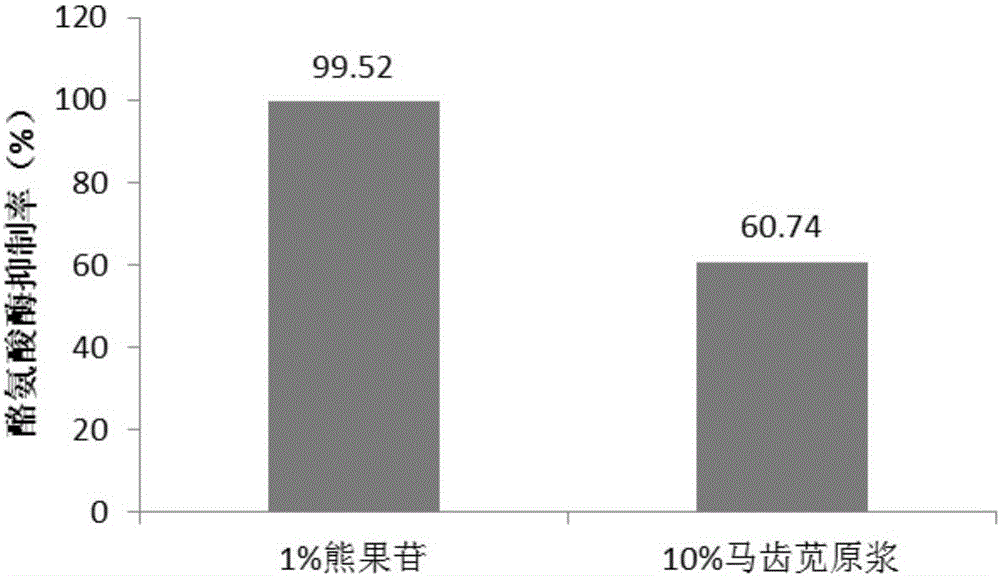

[0051] The component analysis of the purslane fermented puree is carried out, the protein detection method refers to GB5009.5-2010; the crude polysaccharide detection method refers to GB / T5009.8-2008; the flavonoid detection method refers to GB / T5009.124-2003; the tot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com