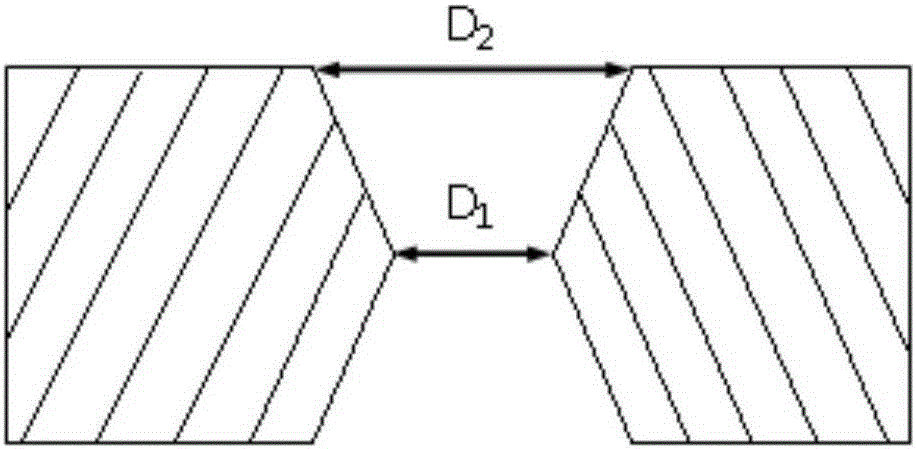

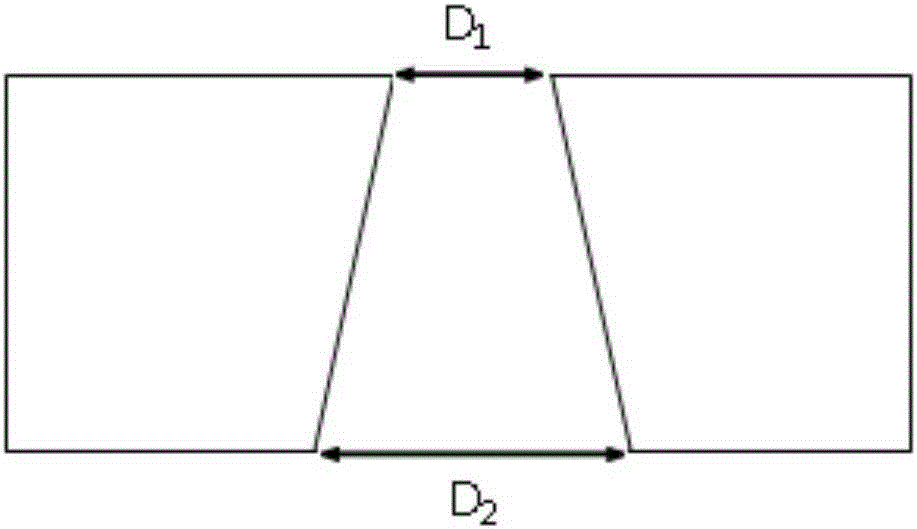

Manufacturing method for nuclear track etching film

A technology of nuclear track etching and manufacturing method, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of difficult single-conical micropore diameter D1, unsuitable for mass production, difficult to operate, etc. , to achieve the effect of easy implementation, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

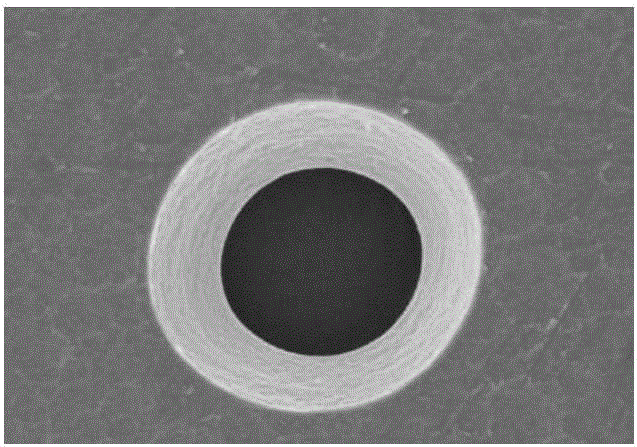

Embodiment 1

[0021] This embodiment is used to illustrate a method for fabricating a nuclear track etching film provided by the present invention. Specific steps are as follows:

[0022] Irradiation: 30μm polyester film is used as the base film; on the tandem accelerator of the China Institute of Atomic Energy, a sulfur ion beam with an energy of 120-500MeV is generated, and the beam intensity is 0.1nA-1mA, which is radiated on the base film , use the energy-reducing sheet in front of the basement film to reduce the energy of the particles, so that the range of ions in the film is 25-28 μm, the irradiation time is 0.1-0.8 seconds, and the latent track density formed on the basement film after irradiation is 1 ×10 5 / cm 2 ;

[0023] Etching: put the irradiated base film into NaOH aqueous solution with a concentration of 8mol / L for etching, the etching time is 20min, and the etching temperature is 70°C;

[0024] Cleaning: use a weak acid solution (pH 2, the same below) and pure water to ...

Embodiment 2

[0028] This embodiment is used to illustrate a method for fabricating a nuclear track etching film provided by the present invention. Specific steps are as follows:

[0029] Irradiation: select the polypropylene film of 50 μm as the base film; irradiate as in the method of embodiment 1, the irradiation depth (the range of the ion in the film) is 45 μm, and the latent track density formed on the base film after irradiation is 1×10 5 / cm 2 ;

[0030] Etching: put the irradiated base film into H2 with a concentration of 6mol / L 2 SO 4 and 0.8mol / L potassium dichromate aqueous solution for etching, the etching time is 50min, and the etching temperature is 75°C;

[0031] Cleaning: Clean the etched base film with weak acid solution and pure water;

[0032] Drying: Dry the cleaned base film in an oven at a temperature of 70°C.

[0033] After testing, the density of the single tapered micropores formed on the microporous membrane made in Example 2 is 1 × 10 4 ~1×10 7 / cm 2 , ...

Embodiment 3

[0035] This embodiment is used to illustrate a method for fabricating a nuclear track etching film provided by the present invention. Specific steps are as follows:

[0036] Irradiation: Select 15 μm polyimide film as the base film; irradiate as in the method of Example 1, the irradiation depth (the range of the ion in the film) is 13 μm, and the latent track formed on the base film after irradiation Density is 6×10 5 / cm 2 ;

[0037] Etching: put the irradiated base film into KMnO with a concentration of 0.5mol / L 4 Soak in the aqueous solution for 20min, then etch with 1mol / L sodium hypochlorite aqueous solution, the etching time is 20min, and the etching temperature is 65°C;

[0038] Cleaning: use weak acid solution and pure water to clean the etched base film;

[0039] Drying: Dry the cleaned base film at a temperature of 70°C.

[0040] After testing, the density of the single tapered micropores formed on the microporous membrane made in Example 3 is 6 × 10 5 / cm 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com