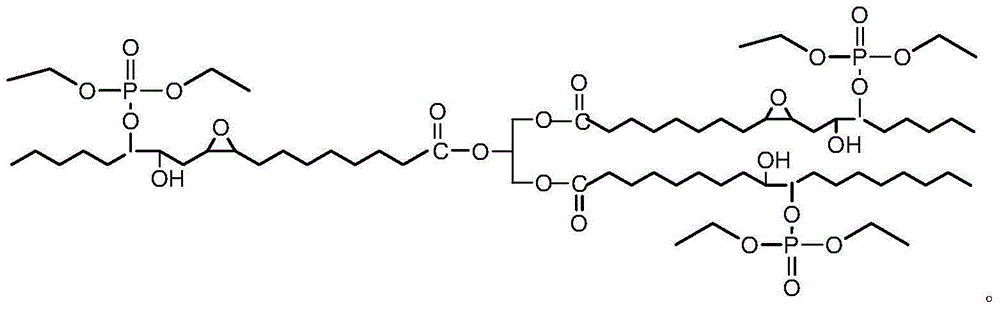

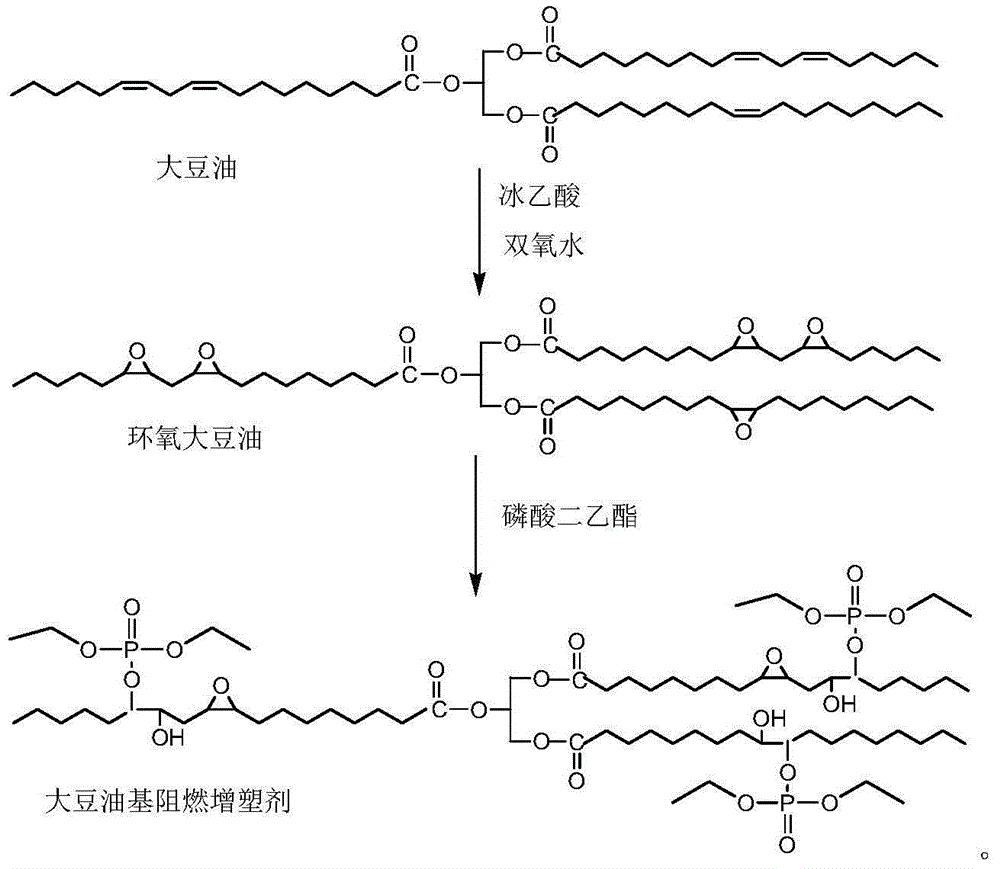

Soybean-oil-based flame-retardant plasticizer, and preparation method and application thereof

A flame retardant plasticizer, soybean oil-based technology, applied in soybean oil-based flame retardant plasticizer and its synthesis, the application field of polyvinyl chloride products, can solve the problem of less research on soybean oil-based flame retardant plasticizer, It does not meet the problems of sustainable development, and achieves the effect of abundant output, low cost and high flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

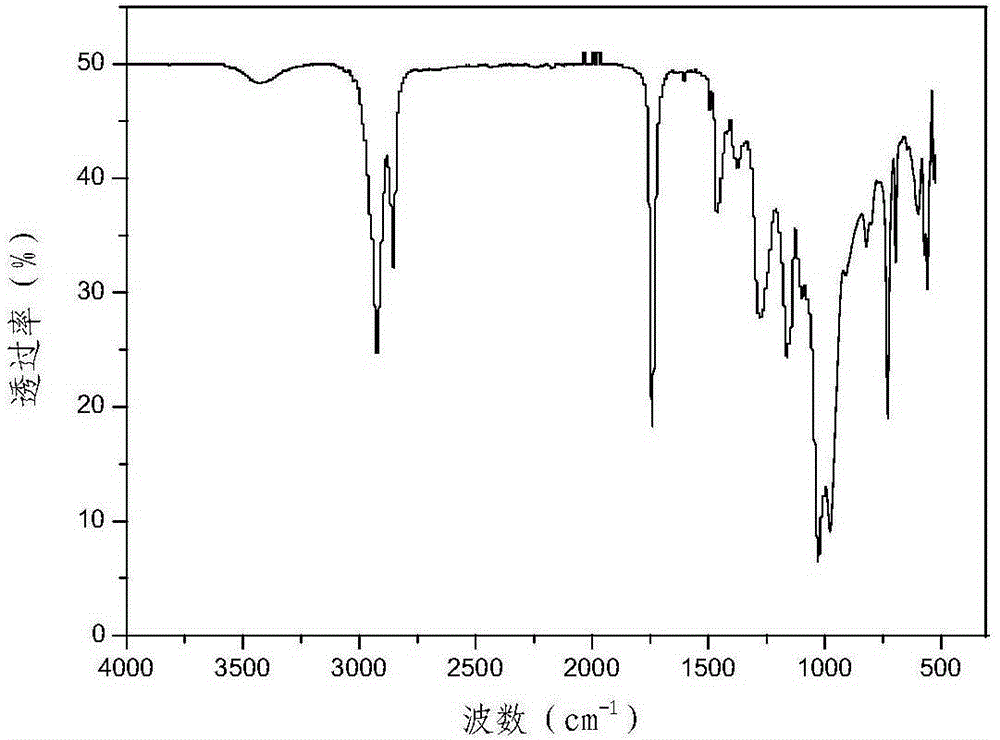

[0028] Step 1: Mix 60 parts by mass of soybean oil, 9 parts by mass of glacial acetic acid, 48 parts by mass of 30%wt hydrogen peroxide, and 0.06 parts by mass of phosphoric acid, react at 50-60°C for 2.6-5 hours, and mix with water and ethyl acetate Wash the ester until pH = 5, then wash with sodium hydroxide solution until neutral, and remove water under reduced pressure at 50°C;

[0029] Step 2: Mix 10 parts by mass of the product obtained in step 1, 1 part by mass of diethyl phosphate, 0.01 parts by mass of triphenylphosphine, and 8 parts by mass of toluene, and react at 70-75°C for 4 hours, and use water Wash with ethyl acetate until pH = 5, then neutralize to neutral with sodium hydroxide solution to obtain the product with an acid value ≤ 2 mg / g.

Embodiment 2

[0031] Step 1: Mix 60 parts by mass of soybean oil, 9 parts by mass of glacial acetic acid, 48 parts by mass of 30%wt hydrogen peroxide, and 0.06 parts by mass of phosphoric acid, react at 50-60°C for 2.6-5 hours, and mix with water and ethyl acetate Wash the ester until pH = 5, then wash with sodium hydroxide solution until neutral, and remove water under reduced pressure at 50°C;

[0032] Step 2: Mix 10 parts by mass of the product obtained in step 1, 2 parts by mass of diethyl phosphate, 0.01 parts by mass of triphenylphosphine, and 8 parts of toluene, and react at 70-75°C for 4 hours, then water and Wash with ethyl acetate until pH = 5, then neutralize to neutral with sodium hydroxide solution to obtain the product with an acid value ≤ 2 mg / g.

Embodiment 3

[0034] Step 1: Mix 60 parts by mass of soybean oil, 9 parts by mass of glacial acetic acid, 57 parts by mass of 30%wt hydrogen peroxide, and 0.06 parts by mass of phosphoric acid, react at 50-60°C for 2.6-5 hours, and mix with water and ethyl acetate Wash the ester until pH = 5, then wash with sodium hydroxide solution until neutral, and remove water under reduced pressure at 50°C;

[0035] Step 2: Mix 10 parts by mass of the product obtained in step 1, 3 parts by mass of diethyl phosphate, 0.02 parts by mass of triphenylphosphine, and 10 parts by mass of toluene, and react at 70-75°C for 4 hours, and use water Wash with ethyl acetate until pH = 5, then neutralize to neutral with sodium hydroxide solution to obtain the product with an acid value ≤ 2 mg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com