Intermittent steam vulcanization calendered and externally bonded earth yellow shoe sole rubber as well as preparation method and application thereof

A rubber sole, khaki technology, applied in the field of rubber processing, can solve the problems of not meeting the needs of users, shortening the service life of rubber shoes, increasing the smell of rubber, etc., achieving good process performance and mechanical performance, improved adhesion performance, and clear patterns. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

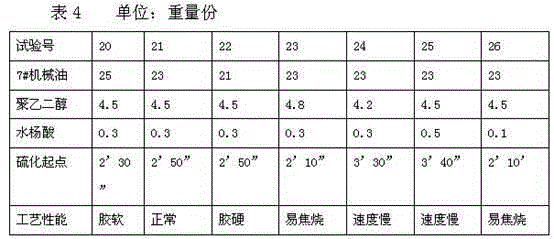

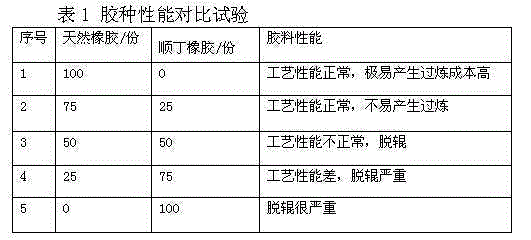

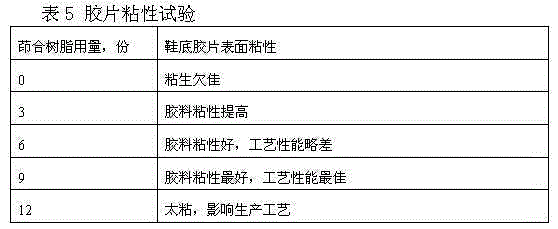

[0031] Embodiment 1 of the present invention: intermediate steam vulcanization and calendering type khaki-colored outer-adhesive rubber sole rubber, calculated by weight fraction, including 80 parts of standard rubber, 20 parts of butadiene rubber, 2 parts of sulfur, and 0.2 part of peptizer DS-T -1, 2.4 parts of vulcanization accelerator, 3 parts of stearic acid, 3 parts of nano zinc oxide, 23 parts of 7# mechanical oil, 50 parts of white carbon black, 4.5 parts of polyethylene glycol, 10 parts light calcium carbonate , 2.5 parts of anti-aging agent, 9 parts of indene resin, 0.3 part of salicylic acid and 1.5 parts of khaki coloring agent; described vulcanization accelerator is that every 2.4 parts of vulcanization accelerator consists of 0.4 part of accelerator DM, 1.6 parts of accelerator DM and 0.4 parts of accelerator DS; the standard glue is 1# standard glue; the specification of polyethylene glycol is PEG-4000; the khaki colorant is composed of anatase titanium dioxide,...

Embodiment 2

[0035]Embodiment 2 of the present invention: intermediate steam vulcanization and calendering type khaki-colored outer-adhesive rubber sole rubber, calculated by weight fraction, including 75 parts of standard rubber, 25 parts of butadiene rubber, 1.8 parts of sulfur, and 0.15 parts of peptizer DS-T -1, 2.2 parts of vulcanization accelerator, 3.5 parts of stearic acid, 3.5 parts of nano zinc oxide, 20 parts of 7# mechanical oil, 48 parts of white carbon black, 4.0 parts of polyethylene glycol, 15 parts light calcium carbonate , 1 part of anti-aging agent, 8 parts of indene resin, 0.4 part of salicylic acid and 1.4 parts of khaki coloring agent; described vulcanization accelerator is that every 2.4 parts of vulcanization accelerator consists of 0.4 part of accelerator DM, 1.6 parts of accelerator DM and 0.4 parts of accelerator DS; the standard glue is 1# standard glue; the specification of polyethylene glycol is PEG-4000; the khaki colorant is composed of anatase titanium diox...

Embodiment 3

[0037] Embodiment 3 of the present invention: intermediate steam vulcanization and calendering type khaki-colored outer-adhesive rubber sole rubber, calculated by weight fraction, including 78 parts of standard rubber, 22 parts of butadiene rubber, 2.2 parts of sulfur, and 0.17 parts of peptizer DS-T -1, 2.6 parts of vulcanization accelerator, 2.5 parts of stearic acid, 2.5 parts of nano zinc oxide, 25 parts of 7# mechanical oil, 45 parts of white carbon black, 4.3 parts of polyethylene glycol, 13 parts light calcium carbonate , 2 parts of anti-aging agent, 10 parts of indene resin, 0.2 part of salicylic acid and 1.6 parts of khaki coloring agent; described vulcanization accelerator is that every 2.4 parts of vulcanization accelerator consists of 0.4 part of accelerator DM, 1.6 parts of accelerator DM and 0.4 parts of accelerator DS; the standard glue is 1# standard glue; the specification of polyethylene glycol is PEG-4000; the khaki colorant is composed of anatase titanium d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com