Preparation method and usage method for slag grinding aid mother liquor

A grinding aid and slag technology, applied in the field of preparation of slag grinding aid mother liquor, can solve the problems of high energy consumption, triethanolamine side reaction, complicated preparation method, etc. simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

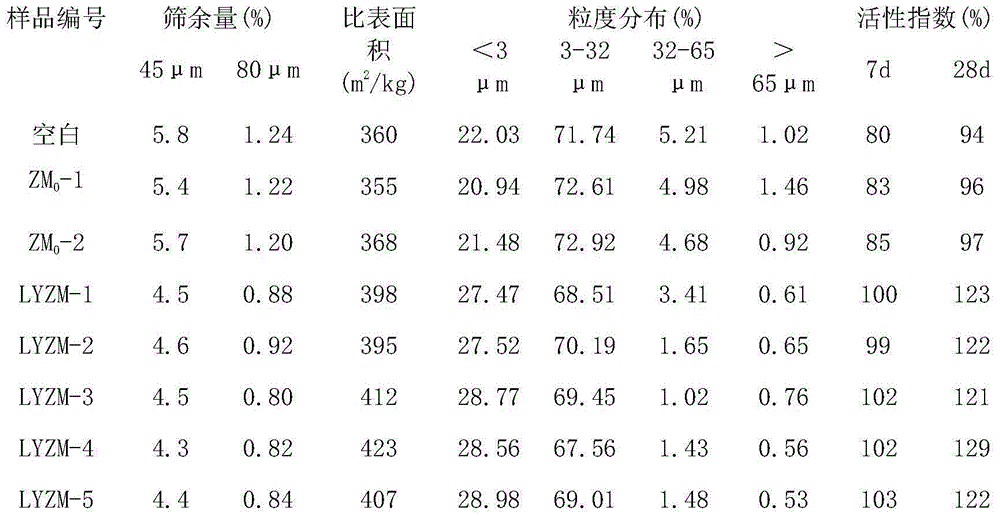

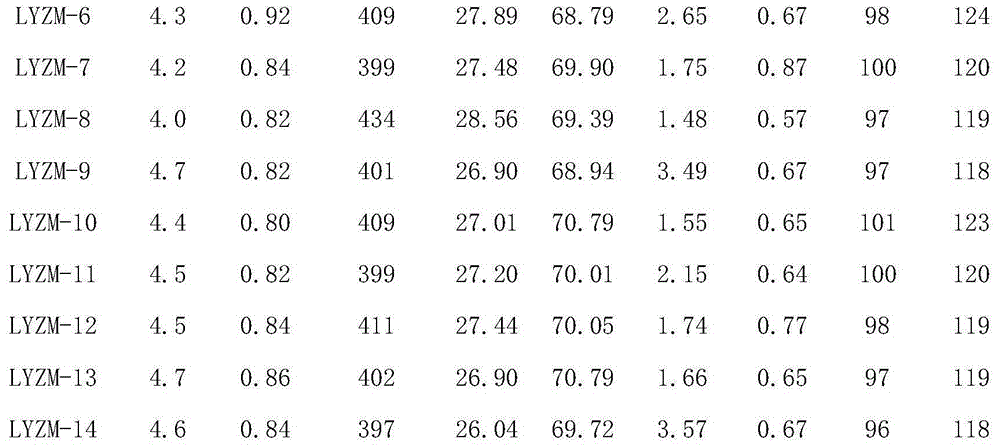

Examples

Embodiment 1

[0031] A kind of preparation method of slag grinding aid mother liquor, comprises the following steps:

[0032] (1) Preparation of amine oxide derivatives:

[0033] At 60°C, 1 mole of peroxide, 1 mole of triethanolamine, and 0.6 mole of water were mixed and stirred for 2 hours to obtain an amine oxide derivative solution;

[0034] (2) Preparation of quaternary ammonium salt type derivatives:

[0035] (21), at 5°C, dissolve 1 mole of polyacid in an appropriate amount of deionized water to prepare a 40wt% aqueous solution of polyacid;

[0036] (22), 2 moles of triethanolamine are added in the polyacid aqueous solution that step (21) obtains, promptly obtain quaternary ammonium salt type derivative solution after stirring for 5min;

[0037] (3) 5 parts of the amine oxide derivative solution obtained in step (1), 8 parts of the quaternary ammonium salt derivative solution obtained in step (22), 5 parts of glycerin, 5 parts of molasses and 77 parts of After mixing and stirring t...

Embodiment 2

[0046] A kind of preparation method of slag grinding aid mother liquor, comprises the following steps:

[0047] (1) Preparation of amine oxide derivatives:

[0048] At 70°C, 1.2 moles of peroxide, 1 mole of triethanolamine, and 0.65 moles of water were mixed and stirred for 4 hours to obtain an amine oxide derivative solution;

[0049] (2) Preparation of quaternary ammonium salt type derivatives:

[0050] (21), at 30°C, dissolve 1 mole of polybasic acid in an appropriate amount of deionized water to prepare a 50wt% polybasic acid aqueous solution;

[0051] (22), 3 moles of diethanol monoisopropanolamine are added in the polyacid aqueous solution that step (21) obtains, promptly obtain quaternary ammonium salt type derivative solution after stirring for 15min;

[0052] (3) 12 parts of the amine oxide derivative solution obtained in step (1), 8 parts of the quaternary ammonium salt derivative solution obtained in step (22), 5 parts of glycerin, 5 parts of molasses and 70 parts o...

Embodiment 3

[0061] A kind of preparation method of slag grinding aid mother liquor, comprises the following steps:

[0062] (1) Preparation of amine oxide derivatives:

[0063] At 60°C, 1 mole of peroxide, 1 mole of diethanol monoisopropanolamine, and 0.6 mole of water were mixed and stirred for 2 hours to obtain an amine oxide derivative solution;

[0064] (2) Preparation of quaternary ammonium salt type derivatives:

[0065] (21), at 5°C, dissolve 1 mole of polyacid in an appropriate amount of deionized water to prepare a 40wt% aqueous solution of polyacid;

[0066] (22), 2 moles of triethanolamine are added in the polyacid aqueous solution that step (21) obtains, promptly obtain quaternary ammonium salt type derivative solution after stirring for 5min;

[0067] (3) 5 parts of the amine oxide derivative solution obtained in step (1), 8 parts of the quaternary ammonium salt derivative solution obtained in step (22), 10 parts of glycerol, 5 parts of molasses and 72 parts of After mixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com