Preparation method of modified tourmaline powder

A technology of tourmaline powder and tourmaline, which is applied in the field of preparation of modified tourmaline powder, can solve the problems that have not yet been achieved, and the performance of tourmaline has not been fully and effectively brought into play, and achieve the effect of improving the biological effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

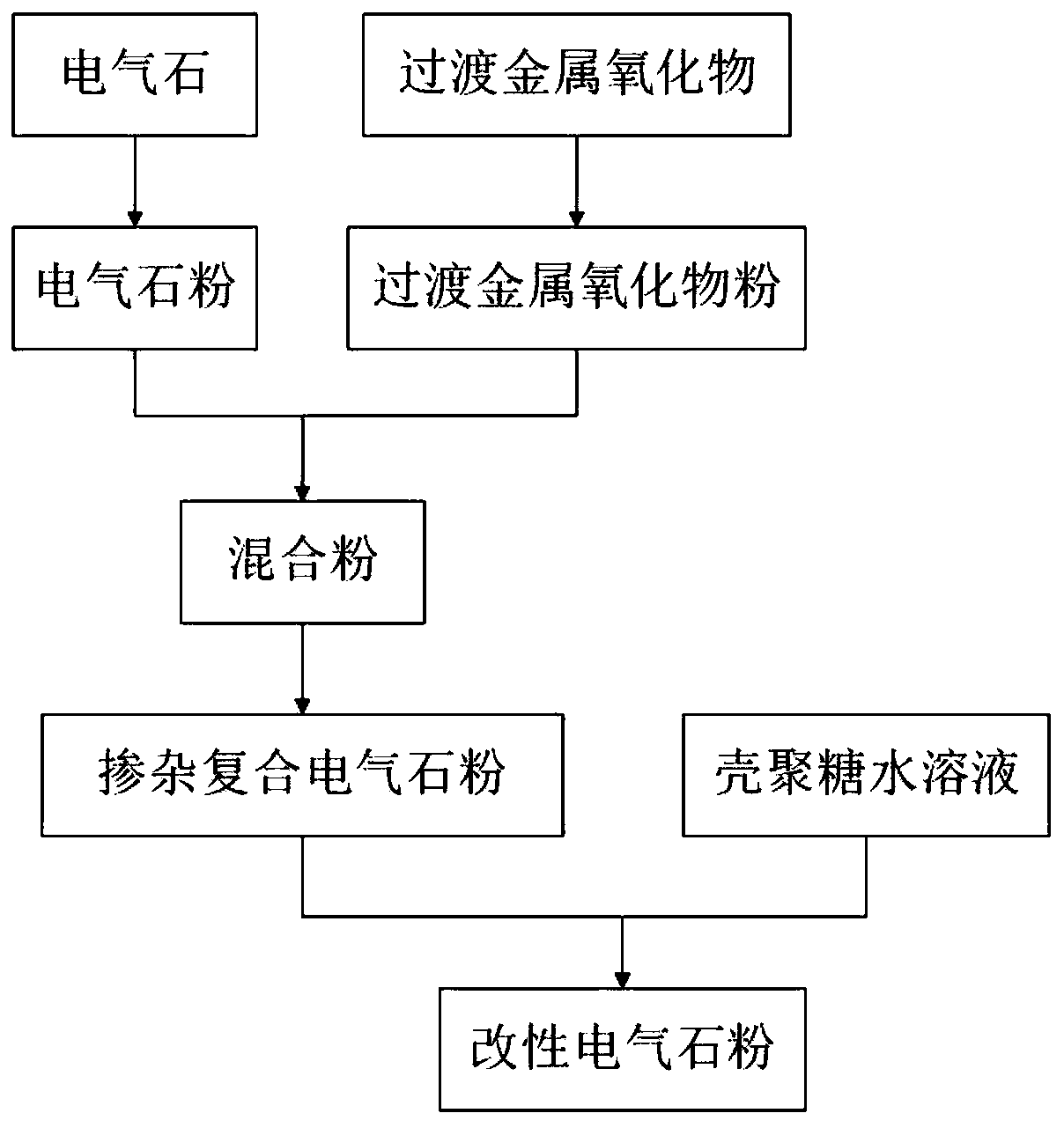

[0033] A kind of preparation method of modified tourmaline powder comprises the following steps:

[0034] 1) Femagnesian tourmaline and transition metal oxides are graded and pulverized respectively, and passed through a 400-mesh sieve, and the pulverized and sieved tourmaline powder and transition metal oxides are mixed at a mass ratio of 20:1 to obtain a mixed powder;

[0035] 2) Put the mixed powder in a muffle furnace, heat up to 550°C at 5°C / min, continue calcining for 2 hours, cool to room temperature, pulverize and pass through a 400-mesh sieve to obtain doped composite tourmaline powder;

[0036] 3) With the assistance of 20Hz ultrasonic vibration, place the doped composite tourmaline powder in 8% chitosan aqueous solution at a ratio of 10:5 (g / ml), wherein the degree of polymerization of chitosan is 6-10, and continue to ultrasonicate 2h, filter, age for 12h, place in a 60°C decompression oven, dry until the moisture content is less than 10%, carry out ultra-fine grin...

Embodiment 2

[0038] A kind of preparation method of modified tourmaline powder comprises the following steps:

[0039] 1) Femagnesian tourmaline and transition metal oxides are graded and crushed respectively, and passed through a 200-mesh sieve, and the pulverized and sieved tourmaline powder and transition metal oxides are mixed at a mass ratio of 15:1 to obtain a mixed powder;

[0040] 2) Put the mixed powder in a muffle furnace, heat up to 550°C at 8°C / min, continue calcining for 4 hours, cool to room temperature, pulverize and pass through a 300-mesh sieve to obtain doped composite tourmaline powder;

[0041] 3) With the assistance of 20Hz ultrasonic vibration, place the doped composite tourmaline powder in 8% chitosan aqueous solution at a ratio of 10:8 (g / ml), wherein the degree of polymerization of chitosan is 3-7, and continue to ultrasonic 2h, filter, age for 12h, place in a 60°C decompression oven, dry until the moisture content is less than 10%, carry out ultra-fine grinding, a...

Embodiment 3

[0043] A kind of preparation method of modified tourmaline powder comprises the following steps:

[0044] 1) Femagnesian tourmaline and transition metal oxides are graded and pulverized respectively, and passed through a 400-mesh sieve, and the pulverized and sieved tourmaline powder and transition metal oxides are mixed at a mass ratio of 18:1 to obtain a mixed powder;

[0045] 2) Put the mixed powder in a muffle furnace, heat up to 400°C at 4°C / min, continue calcining for 6 hours, cool to room temperature, pulverize and pass through a 200-mesh sieve to obtain doped composite tourmaline powder;

[0046] 3) With the assistance of 20Hz ultrasonic vibration, place the doped composite tourmaline powder in 8% chitosan aqueous solution at a ratio of 10:8 (g / ml), wherein the degree of polymerization of chitosan is 6-10, and continue to ultrasonicate 2h, filtered, aged for 12h, placed in a 60°C decompression oven, dried until the moisture content was less than 10%, ultra-finely groun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com