Chromium-doped red fluorescent powder and preparation method thereof

A red phosphor, photoactive technology, applied in the field of phosphor, can solve the problems of shortage, difficulty in reaching the deep red area, expensive phosphor, etc., and achieve the effect of uniform size, high purity and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] (1) Accurately weigh Cr(NO 3 ) 3` 9H 2 O, Ga 2 o 3 , ZnAc 2` 9H 2 O, control the molar ratio of Zn:Ga:Cr to 1:2:0.0516.

[0017] (2) Mechanically mix the above-mentioned raw materials after weighing, and sinter at 1200° C. for 3.5 hours;

[0018] (3) The sintered product is cooled to room temperature, ball milled, and passed through a mesh sieve to obtain the red phosphor.

Embodiment 2~4

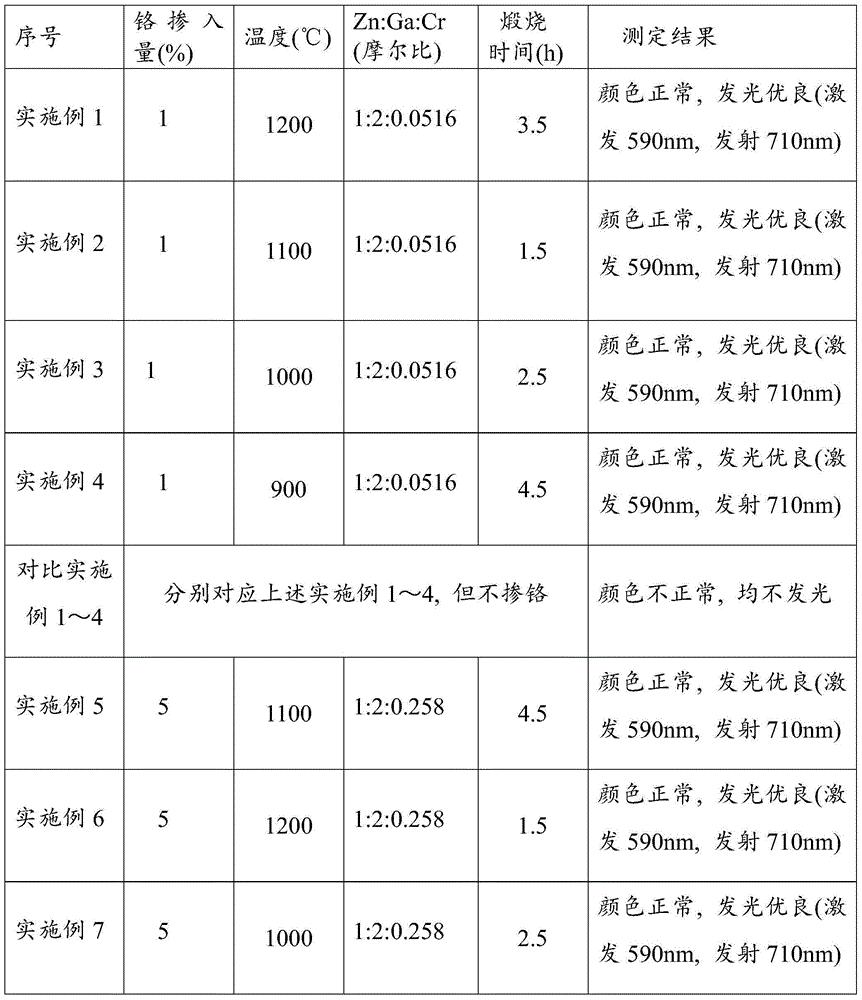

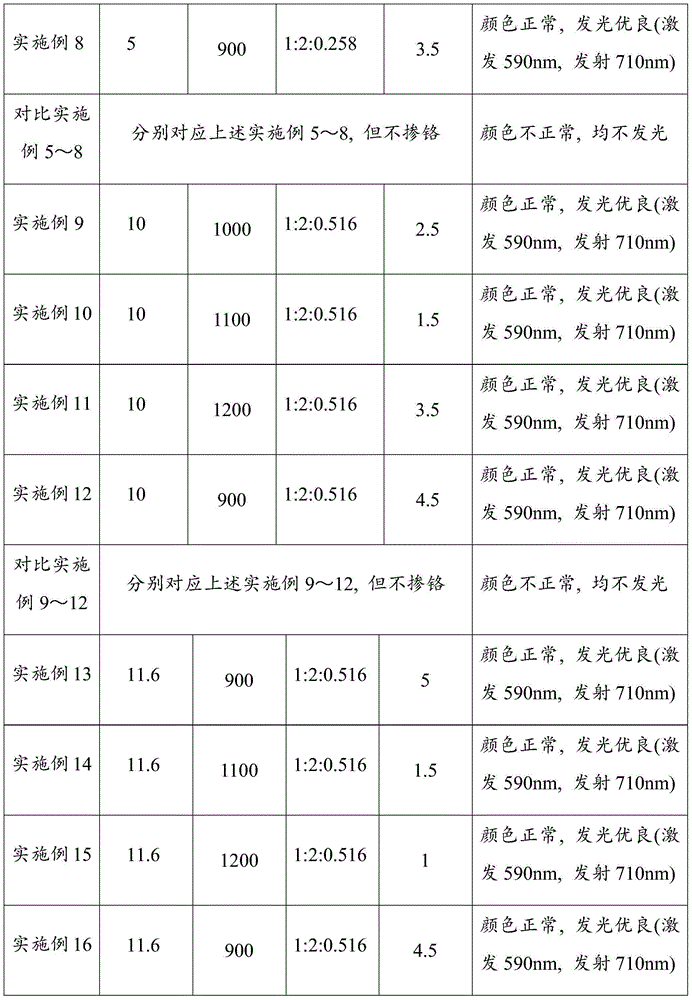

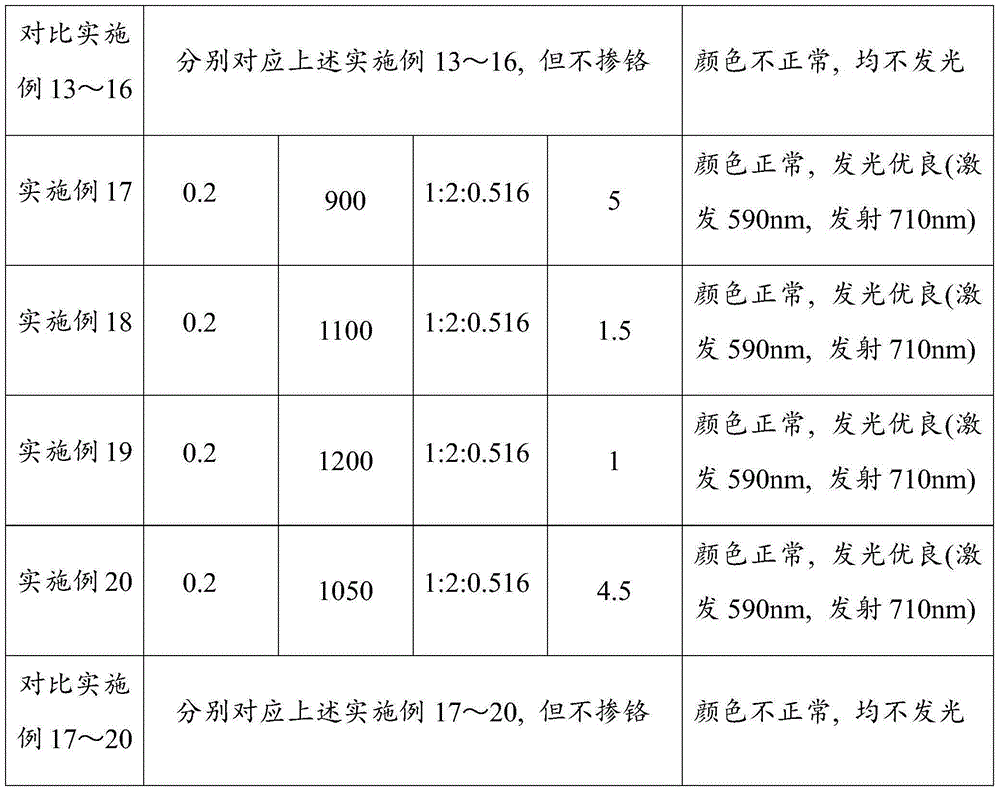

[0019] Embodiment 2~4: the reaction raw material ratio is the same as embodiment 1, but reaction temperature and reaction time change, and concrete situation and experimental result are shown in Table 1.

[0020] Comparative examples 1~4: reaction raw material ratio and reaction temperature, reaction time are respectively with embodiment 1~4, but do not mix chromium in the reaction raw material, experimental result is shown in Table 1.

Embodiment 5

[0022] (1) Accurately weigh Cr(NO 3 ) 3` 9H 2 O, Ga 2 o 3 , ZnAc 2` 9H 2 O, control the molar ratio of Zn:Ga:Cr to 1:2:0.256.

[0023] (2) Mechanically mix the above-mentioned raw materials after weighing, and sinter at 1100° C. for 4.5 hours;

[0024] (3) The sintered product is cooled to room temperature, ball milled, and passed through a mesh sieve to obtain the red phosphor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com