Cordyceps sinensis liquid state fermentation culture medium for producing exopolysaccharides

An extracellular polysaccharide, liquid fermentation technology, applied in microorganism-based methods, fermentation, microorganisms, etc., can solve the problems of low yield of extracellular polysaccharide and insignificant effect, and achieve the effect of increasing yield, low cost and promoting growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

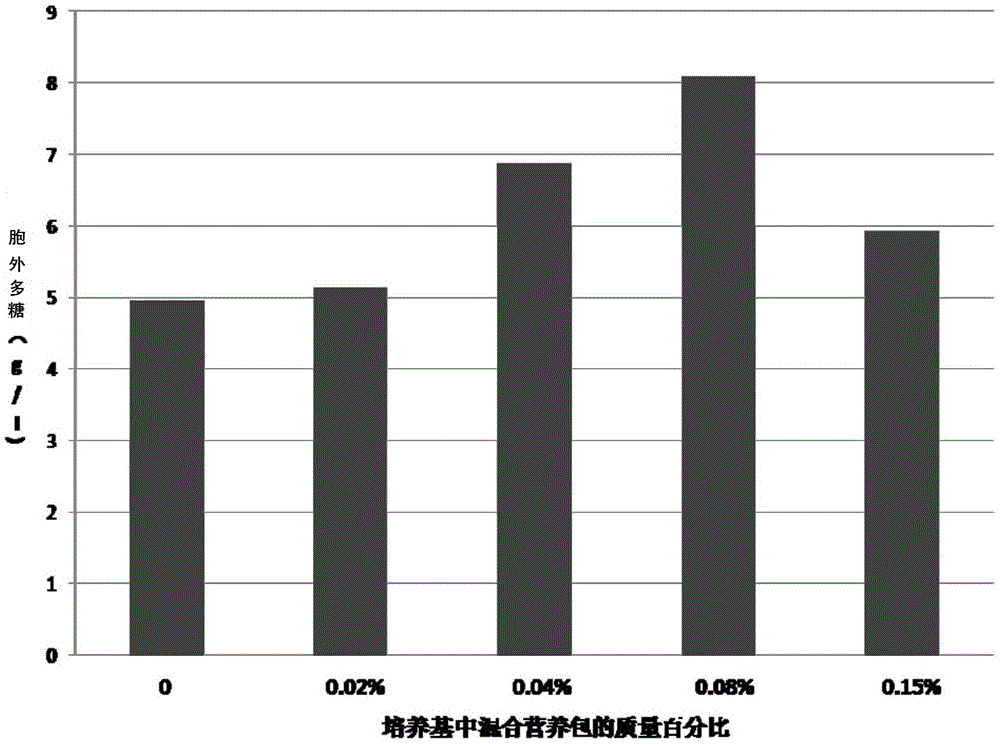

Embodiment 1

[0028] (1) Preparation of liquid medium: by mass percentage, it includes glucose 3%, peptone 1.5%, yeast powder 0.5%, KH 2 PO 4 0.3%, MgSO 4 ·7H 2 O0.15% and potato 20%, the solvent is water, and the pH value of the liquid medium is 6.0;

[0029] (2) Fermentation culture: put the prepared fermentation medium into a fermenter with a capacity of 1 L, sterilize, inoculate the strains into the liquid medium under aseptic conditions, and cultivate at a constant temperature at 24°C and 150r / min;

[0030] (3) After the fermentation finishes, use a microscope to observe the growth of mycelia in the fermented liquid, and inoculate the fermented liquid on the nutrient agar plate to check whether it is infected with bacteria;

[0031] (4) Centrifuge the uninfected fermentation broth detected in step (3) at 4000r / min for 20min to obtain the fermented mycelia in the form of pellets, and then freeze-dry the mycelium and supernatant and stored in a -18°C refrigerator for later use;

[0...

Embodiment 2

[0036] (1) Preparing a nutrition package, the mixed nutrition package includes by mass percentage: 31.1% histidine, 31.1% lysine, 18.3% glutamine, 18.3% vitamin B2 and 1.2% selenium;

[0037] (2) Preparation of liquid medium: a medium for the production of exopolysaccharides by liquid fermentation of Cordyceps sinensis comprising: 0.02% mixed nutrition package, 3% glucose, 1.5% peptone, 0.5% yeast powder, KH 2 PO 4 0.3%, MgSO 4 ·7H 2 O0.15% and potato 20%, the solvent is water, and the pH value of the liquid medium is 6.0;

[0038] (3) Fermentation culture: put the prepared fermentation medium into a fermenter with a capacity of 1 L, sterilize, inoculate the strains into the liquid medium under aseptic conditions, and cultivate at a constant temperature at 24°C and 150r / min;

[0039] (4) After the fermentation finishes, use a microscope to observe the growth of mycelia in the fermented liquid, and inoculate the fermented liquid onto the nutrient agar plate to check whether ...

Embodiment 3

[0045] (1) Preparing a nutrition package, the mixed nutrition package includes by mass percentage: 31.1% histidine, 31.1% lysine, 18.3% glutamine, 18.3% vitamin B2 and 1.2% selenium;

[0046] (2) Preparation of liquid medium: a medium for the production of exopolysaccharides by liquid fermentation of Cordyceps sinensis, including: 0.04% mixed nutrition package, 3% glucose, 1.5% peptone, 0.5% yeast powder, KH 2 PO 4 0.3%, MgSO 4 ·7H 2 O0.15% and potato 20%, the solvent is water, and the pH value of the liquid medium is 6.0;

[0047] (3) Fermentation culture: put the prepared fermentation medium into a fermenter with a capacity of 1 L, sterilize, inoculate the strains into the liquid medium under aseptic conditions, and cultivate at a constant temperature at 24°C and 150r / min;

[0048] (4) After the fermentation finishes, use a microscope to observe the growth of mycelia in the fermented liquid, and inoculate the fermented liquid onto the nutrient agar plate to check whether ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com