Automatic adjusting device and method for converter second venturi throat

An automatic adjustment and throat technology, applied in the manufacture of converters, etc., can solve the problems of difficult sensor maintenance, high failure rate, cumbersome control process, etc., and achieve the effect of improving gas recovery rate, significant economic benefits, and reducing accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

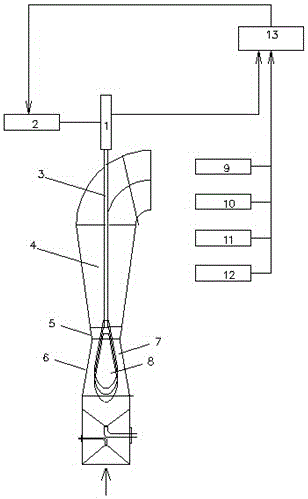

[0027] The automatic adjustment device for the second-stage throat of the converter of the present invention includes a magnetic scale hydraulic cylinder 1, a hydraulic servo control station 2, a connecting rod 3, a secondary venturi expansion section 4, a throat 5, a secondary venturi contraction section 6, Heavy weight 8, PLC industrial computer 13.

[0028] The figure shows that the signal output terminal of the PLC industrial computer 13 is connected with the hydraulic servo control station 2, the hydraulic servo control station 2 is connected with the magnetic ruler hydraulic cylinder 1, and the magnetic ruler hydraulic cylinder 1, the connecting rod 3 and the weight 8 pass through the pin The shaft is connected as a whole, the expansion section 4 of the secondary venturi tube, the throat 5 and the contraction section 6 of the secondary venturi tube are welded and connected, and the PLC industrial computer 13 controls the magnetic ruler hydraulic cylinder 1 to move up and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com