Method for eliminating loess foundation collapsibility through microwave heating

A microwave heating and microwave heating device technology, applied in the field of geotechnical engineering, can solve problems such as incomplete elimination of collapsibility, reduction of soil strength, and limited heating methods, etc., to achieve easy promotion and use, high heat utilization efficiency, and elimination of moisture trapping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

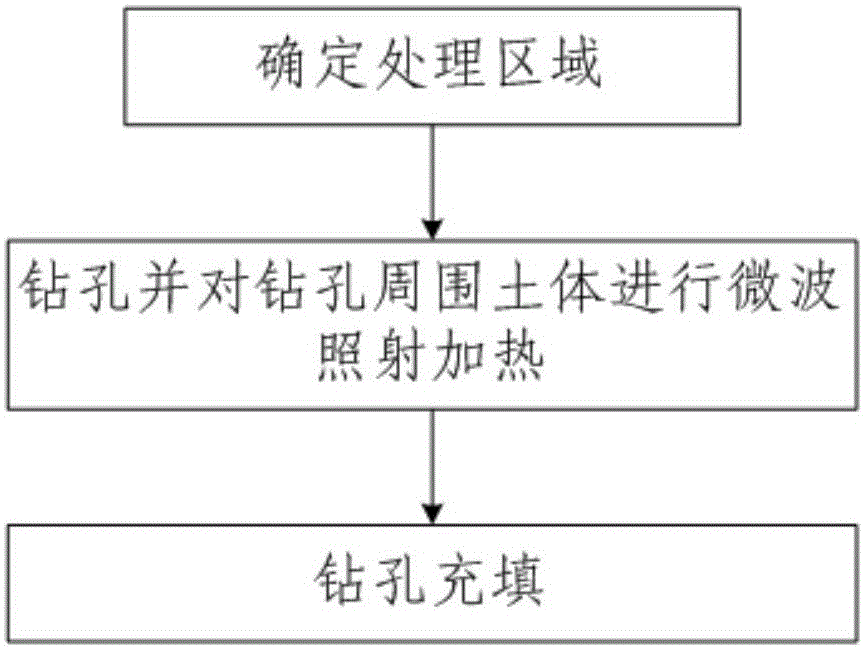

[0036] Such as figure 1 Shown, microwave heating of the present invention eliminates the method for loess foundation collapsibility, comprises the following steps:

[0037] Step 1. Determining the treatment area: according to the building code for collapsible loess areas (GB50025-2004), determine the plane treatment range and treatment thickness of the collapsible loess foundation;

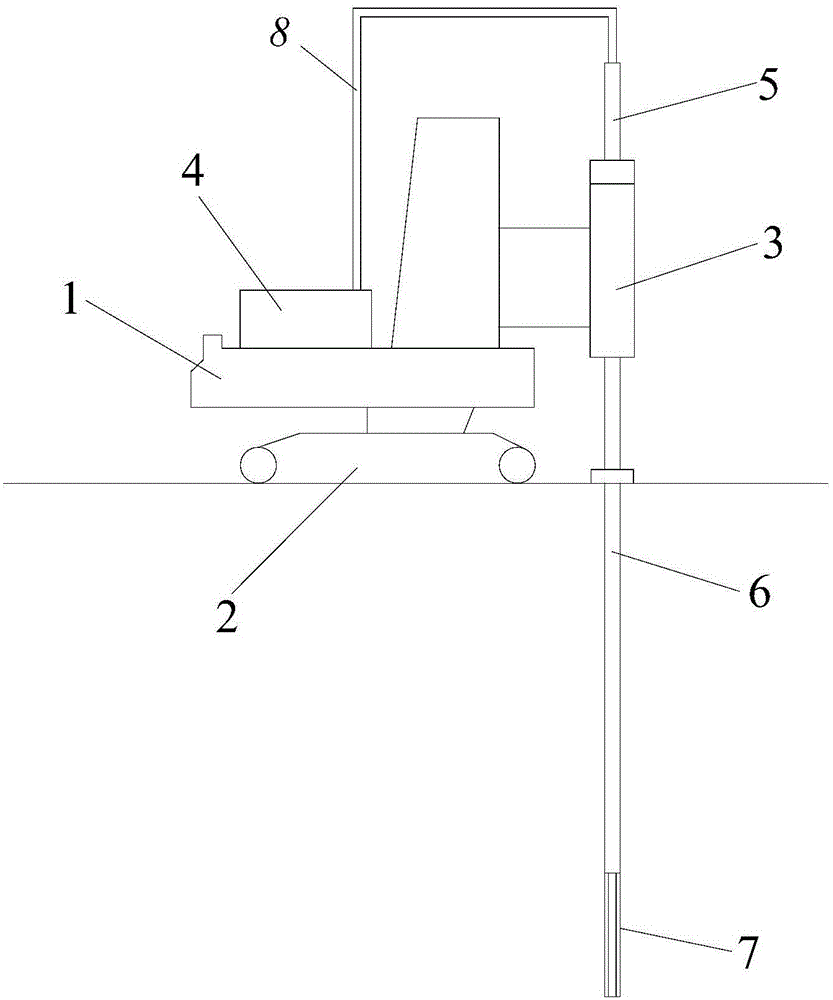

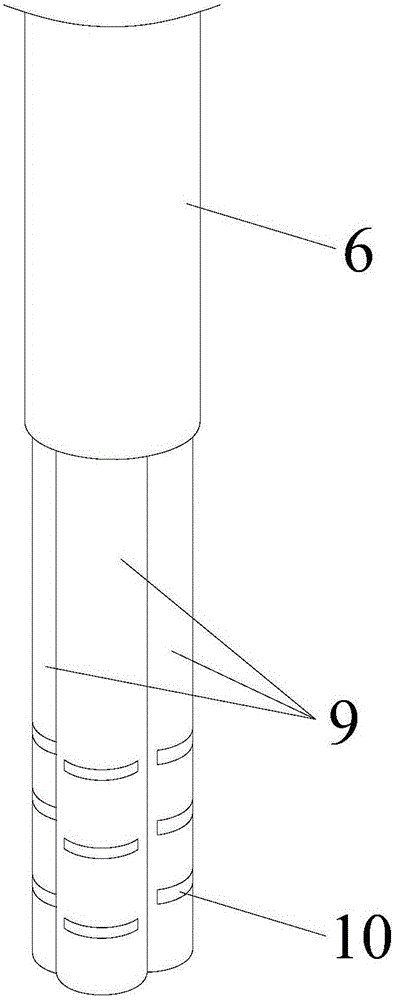

[0038] Step 2. Drilling and heating the soil around the drilling hole with microwave irradiation: use an engineering geological drilling rig to drill the hole, the depth of the drilling hole is the same as the thickness of the collapsible loess foundation, and the layout of the drilling holes is quincunx, rectangular or Rectangular, the distance between two adjacent boreholes is 400mm ~ 1500mm; in the process of drilling, each time a borehole is drilled, the soil around the borehole is heated by a microwave heating device from bottom to top. Carry out microwave irradiation heating in sections;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com