Handset casing testing apparatus and method based on computer vision

A technology of computer vision and mobile phone casing, applied in computing, image data processing, instruments, etc., can solve problems such as uneven stretching during cooling time, irregular rounded corners, warping of rough products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0097] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

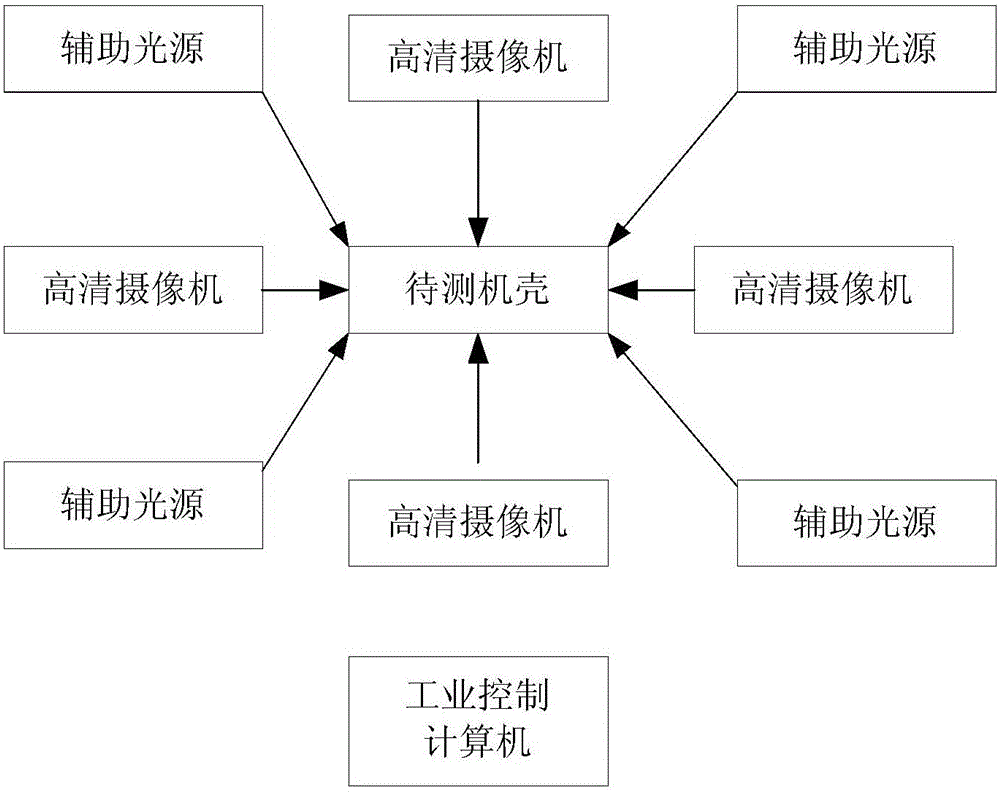

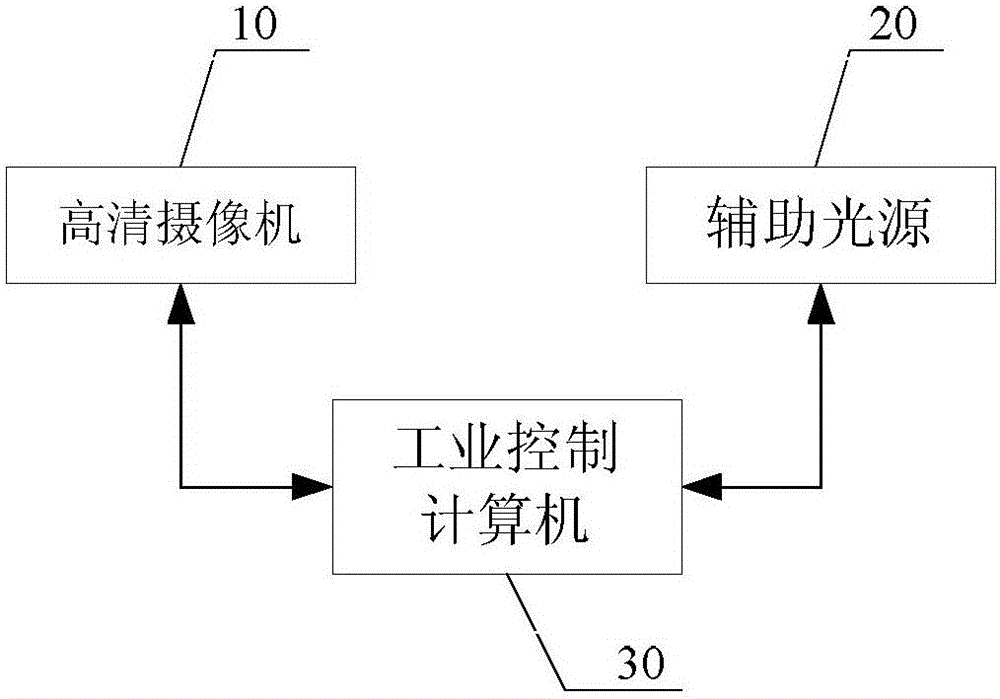

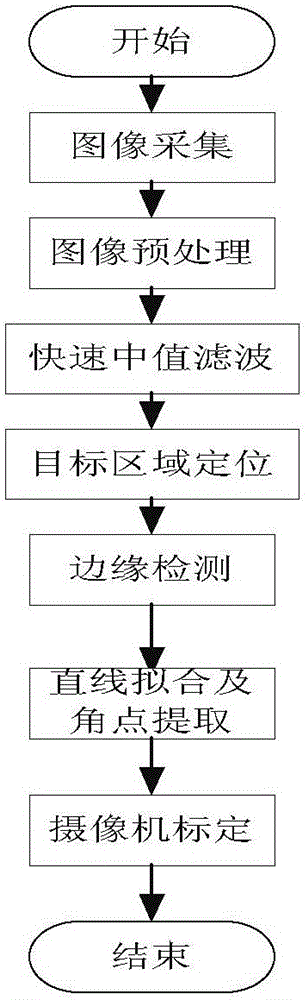

[0098] figure 1 It is a physical schematic diagram of the mobile phone shell detection device of the present invention; figure 2 It is a block diagram of the composition of the mobile phone shell detection device of the present invention; as figure 1 figure 2 Shown, a kind of mobile phone case inspection device based on computer vision of the present invention comprises, high-definition camera 10, auxiliary light source 20 and industrial control computer 30; The light source 20 is arranged at the mobile phone casing inspection station of the production line, which can capture the position of the mobile phone casing that needs to be accurately inspected, and is used to collect images of the mobile phone casing to be inspected; the industrial control computer 30 is connected with the high-definition camera 10 and the auxiliary light source 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com