Organic light emitting diode (OLED) display panel, preparation method thereof and display device

An electroluminescence display and display panel technology, which is applied in the direction of circuits, electrical components, and electric solid-state devices, and can solve problems such as low product resolution and complex manufacturing process of OLED display panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

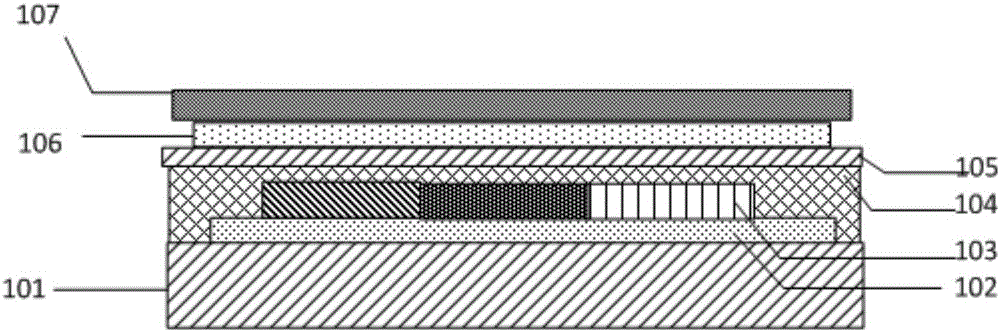

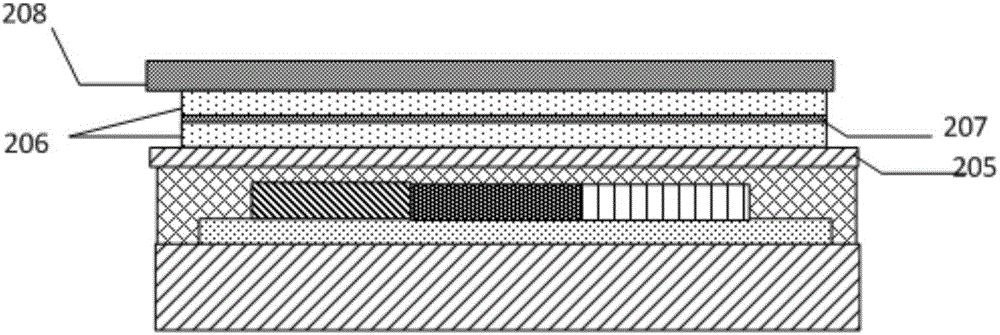

[0063] Based on the same inventive concept, an embodiment of the present invention provides a method for preparing an organic electroluminescent display panel, such as Figure 8 As shown, the following steps may be specifically included:

[0064] S101, forming a switching transistor array on a flexible substrate through a patterning process;

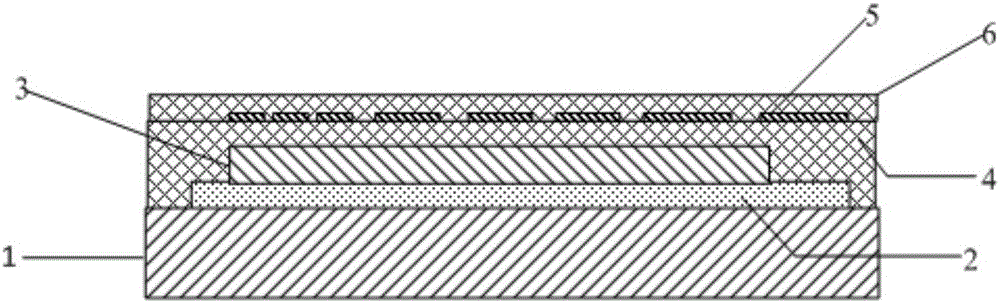

[0065] S102, forming a white organic light emitting diode on the flexible substrate formed with the switch transistor array;

[0066] S103, performing a thin film packaging process on the flexible substrate formed with white organic light emitting diodes to form a first packaging film;

[0067] S104, forming metal color filters with periodic nanostructures on the flexible substrate formed with the first encapsulation film by photolithography;

[0068] S105 , performing a thin film packaging process on the flexible substrate on which the metal color filter is formed, to form a second packaging film.

[0069] In the method for preparing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com