Silicon-based OLED display pixel preparation method

A display pixel and silicon-based technology, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problems of insufficient dimensional accuracy and positioning accuracy of RGB pixel areas, unreasonable color mixing ratio, and color distortion of display images, etc. , to achieve normal image color, reduce sheet resistance, and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

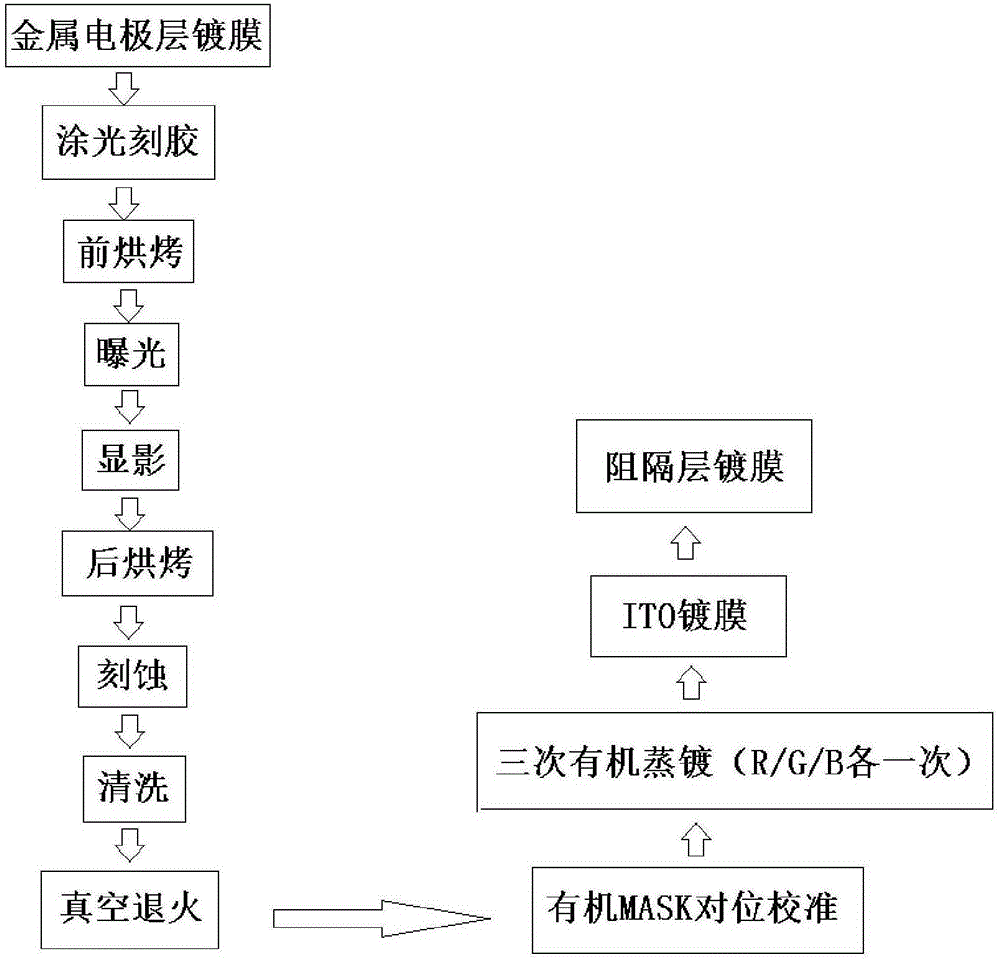

[0033] Such as figure 1 As shown, this embodiment provides a method for manufacturing a silicon-based OLED display pixel, which includes a pixel backplane process and an organic light-emitting layer process, wherein the pixel backplane process includes:

[0034] (1) Metal electrode layer coating is carried out on the monocrystalline silicon substrate, and the substrate pretreatment is carried out before the coating: the monocrystalline silicon substrate is ultrasonically cleaned with deionized water for 2 minutes at 80 ° C in an ultrasonic cleaning device, and then The substrate was rinsed with deionized water at a speed of 1500rpm / min for 1min, and then dried at a high speed of 2500rpm for 1min after cleaning, then put into a nitrogen protection oven and baked for 3min. Using magnetron sputtering coating equipment, Ti / Al / Pt three-layer metal stacked electrodes were fabricated sequentially, with thicknesses of and The coating rate is and Obtain a metal electrode layer;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com