A kind of environment-friendly polymer battery manufacturing method capable of high current charging and discharging

A polymer and lithium-ion battery technology, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, electrodes, etc., to achieve the effects of reasonable design, good environmental protection, and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

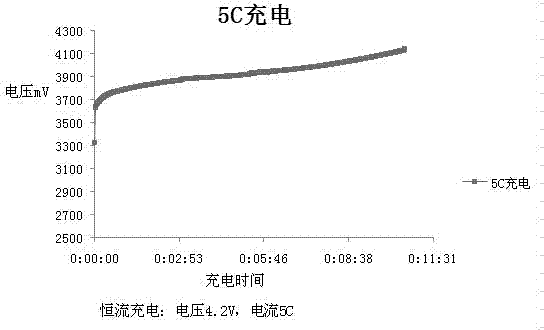

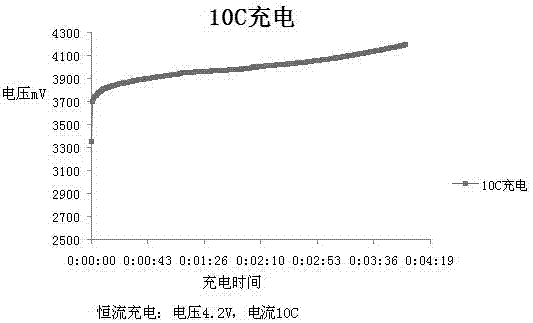

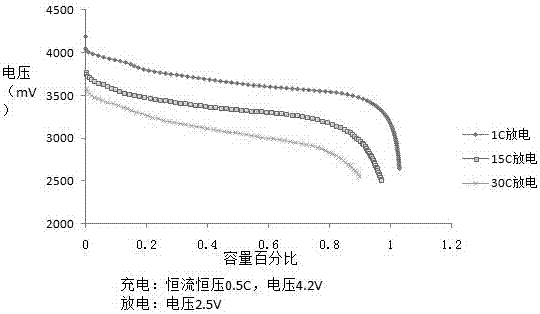

Image

Examples

Embodiment 1

[0026] A polymer lithium-ion battery with a fast charge and fast discharge rate, which includes a positive electrode sheet, a negative electrode sheet, a diaphragm and an aluminum-plastic composite film; the positive electrode is composed of a positive electrode slurry and a positive electrode current collector, and the negative electrode is composed of Composition of negative electrode slurry and negative electrode current collector;

[0027] The positive electrode slurry includes: 85% ternary materials, 3% conductive graphite, 2% carbon nanotubes, 6% polyvinylidene fluoride, the dispersant is a nonionic surfactant, and the solid content of the slurry is 50% %, the slurry is evenly distributed on the upper and lower surfaces of the current collector, and the surface density of the slurry is controlled at 22mg / cm 2 ;

[0028] The negative electrode slurry includes 75% graphite, 10% graphene, 0.5% conductive graphite, 4% carbon nanotubes, 4% polyvinylidene fluoride, the disper...

Embodiment 2

[0036] A polymer lithium-ion battery with a fast charge and fast discharge rate, which includes a positive electrode sheet, a negative electrode sheet, a diaphragm and an aluminum-plastic composite film; the positive electrode is composed of a positive electrode slurry and a positive electrode current collector, and the negative electrode is composed of Composition of negative electrode slurry and negative electrode current collector;

[0037] The positive electrode slurry includes: 88% ternary materials, 0.5% conductive graphite, 5% carbon nanotubes, 4% polyvinylidene fluoride, the dispersant is a nonionic surfactant, and the solid content of the slurry is 55% %, the slurry is evenly distributed on the upper and lower surfaces of the current collector, and the surface density of the slurry is controlled at 18mg / cm 2 ;

[0038] The negative electrode slurry includes 80% graphite, 8% graphene, 2% conductive graphite, 2% carbon nanotubes, 6% polyvinylidene fluoride, the dispers...

Embodiment 3

[0046] A polymer lithium-ion battery with a fast charge and fast discharge rate, which includes a positive electrode sheet, a negative electrode sheet, a diaphragm and an aluminum-plastic composite film; the positive electrode is composed of a positive electrode slurry and a positive electrode current collector, and the negative electrode is composed of Composition of negative electrode slurry and negative electrode current collector;

[0047]The positive electrode slurry includes: 86% ternary materials, 2% conductive graphite, 3% carbon nanotubes, 5% polyvinylidene fluoride, the dispersant is a nonionic surfactant, and the solid content of the slurry is 51 %, the slurry is evenly distributed on the upper and lower surfaces of the current collector, and the surface density of the slurry is controlled at 21mg / cm 2 ;

[0048] The negative electrode slurry includes 76% graphite, 9% graphene, 1% conductive graphite, 3% carbon nanotubes, 5% polyvinylidene fluoride, the dispersant ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com