Connecting method and connecting structure of valve reactor and voltage source transverter in flexible direct current power transmission

A flexible direct current transmission and voltage source converter technology, which is applied in the installation of cables, power distribution substations, electrical components, etc., can solve the problems of heavy operation and maintenance workload, bulky transition busbar, poor flexibility and adaptability, etc. Operation and maintenance, reducing the total length of wiring, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

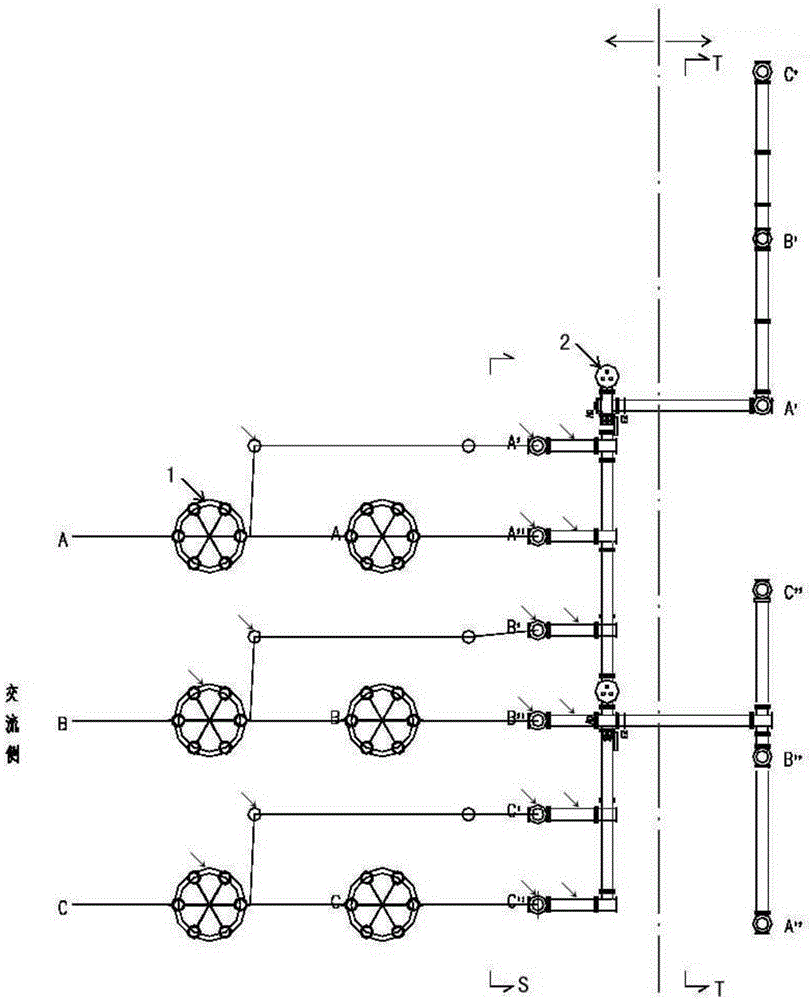

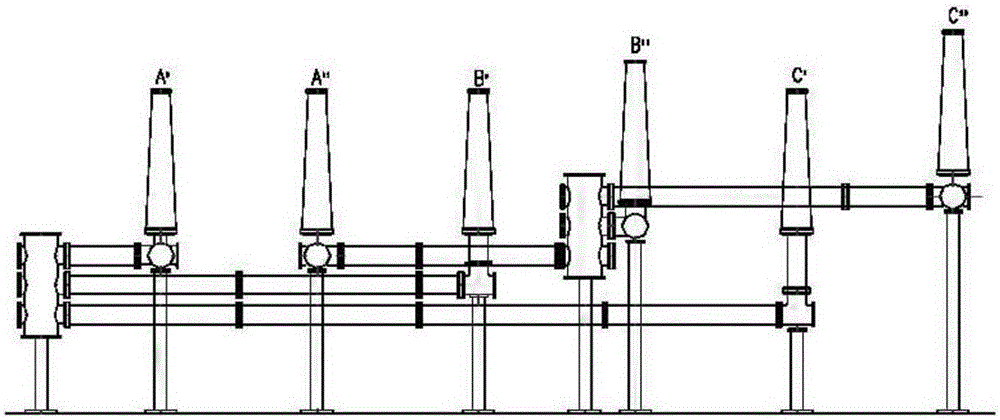

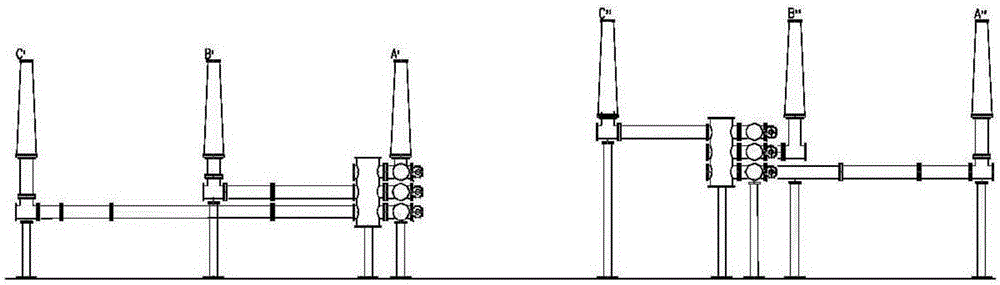

[0043] refer to Figure 1 to Figure 3 , the connection structure between the valve reactor and the voltage source converter in the flexible DC transmission involved in this embodiment includes the valve reactor on the AC side and the converter in the valve hall, and its structural features are: the valve reactance on the AC side The gas-insulated metal-enclosed transmission line structure GIL is set at the junction of the inverter and the converter in the valve hall. The gas-insulated metal-enclosed transmission line structure GIL is SF6GIL, and its segmental assembly and testing are completed in the factory. The maximum segment length is 18 m, the elbow section is pre-assembled in the factory, and its bending angle is 79° to 179°, which is used to change the line direction to reduce the total length of wiring. GIL also has pre-assembled T-shaped pipe sections, which are convenient for connecting branch circuits and other system components. Including SF6 arrester and voltage t...

specific Embodiment 2

[0056] The characteristics of this embodiment are: the layout of the GIL outlet bushings is flexibly adjusted according to the layout requirements of the valve reactors and converters, and the valve reactors on the AC side are arranged in parallel double rows according to the upper and lower bridge arms. The converter station of flexible direct current transmission is designed according to indoor multi-layer layout, and the whole station is divided into 110kV AC power distribution device area, connecting transformer area, starting circuit and valve reactor area, valve hall area and DC field area according to electrical functions; , 110kV AC power distribution device area, connecting transformer area, starting circuit and valve reactor area are located on the first floor of the AC and DC power distribution device building, the valve hall and DC field are arranged on the second floor of the AC and DC power distribution device building, and the valve reactor The connection with th...

specific Embodiment 3

[0057] The feature of this embodiment is that compressed air is used to replace SF6 in the GIL to reduce costs and benefit environmental protection, and at the same time adopts a tubular structure, which is not affected by the environment. The use of this technology can effectively save the occupied area, has strong safety, is convenient for maintenance, and prevents the occurrence of vicious accidents caused by climate. The analysis shows that CAIL is a promising new environmentally friendly connection method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com