A kind of anti-tumor solid element microparticle capsule

A technology of capsules and particles, which is applied in the fields of capsule delivery, anti-toxic agents, and medical preparations containing active ingredients, etc. It can solve the problems of slow disintegration release speed, large dosage, and low yield of tablets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A solid yuan microparticle capsule, containing 216.7g of astragalus polysaccharide, 55.7g of ginseng reed head and 77.6g of calcium carbonate.

[0024] Its preparation method is:

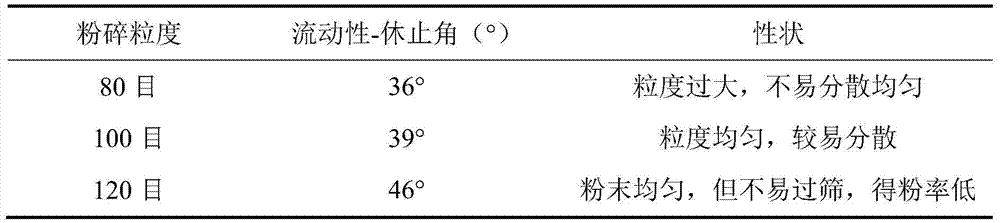

[0025] 1. Grind ginseng and reed heads in proportion, pass through a 80-mesh sieve, then take 60% of the calcium carbonate in the formula and mix them with ginseng and reed heads, and then grind them together for 3 hours at a grinding temperature of 5°C; pass through a 300-mesh sieve;

[0026] 2. Take astragalus polysaccharide, add the remaining amount of calcium carbonate and mix for 2 hours, the mixing temperature is 15°C; then add the ginseng and reed head mixture in step (1), mix evenly, and granulate with 85% ethanol to form 200 meshes; dried at 60°C, whole grains, packed into capsules.

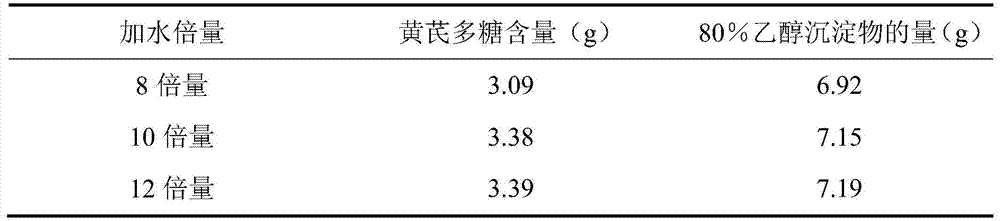

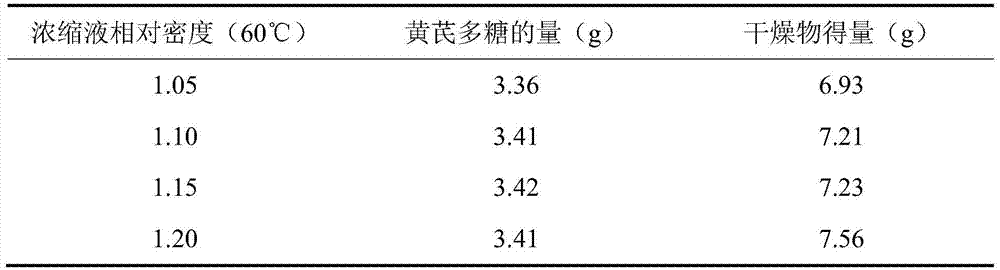

[0027] The preparation method of astragalus polysaccharide is as follows: take 100g of astragalus, add 10 times the amount of water to decoct three times, the first time for 3 hours, the second and thi...

Embodiment 2

[0029] A solid element microparticle capsule, which contains 200g of astragalus polysaccharide, 50g of ginseng reed head and 60g of calcium carbonate.

[0030] Its preparation method is:

[0031] 1. Grind ginseng and reed heads in proportion, pass through a 50-mesh sieve, then take 50% of the calcium carbonate in the formula and mix them with ginseng and reed heads for 4 hours. The grinding temperature is 8°C; pass through a 400-mesh sieve;

[0032] 2. Take astragalus polysaccharide, add the remaining amount of calcium carbonate and mix for 2.5 hours. The temperature of mixing is 12°C; 240 mesh; dried at 55°C, whole grains, packed in capsules.

[0033] The preparation method of astragalus polysaccharide is as follows: take 100g of astragalus, add 10 times the amount of water to decoct three times, the first time for 3 hours, the second and third times for 2 hours each, combine the decoction, filter, and the filtrate is at 60 ~ 70 ℃, - Concentrate under reduced pressure to a ...

Embodiment 3

[0035] The solid yuan microparticle capsule contains 220g of astragalus polysaccharide, 60g of ginseng reed head and 80g of calcium carbonate.

[0036] Its preparation method is:

[0037] 1. Grind ginseng and reed heads in proportion, pass through a 60-mesh sieve, then take 70% of the calcium carbonate in the formula and mix them with ginseng and reed heads for 4 hours. The grinding temperature is 10°C and pass through a 325-mesh sieve;

[0038] 2. Take astragalus polysaccharide, add the remaining amount of calcium carbonate and mix for 1 hour, the mixing temperature is 15°C; then add the ginseng and reed head mixture in step (1), mix evenly, and granulate with 85% ethanol to form 230 mesh; dried at 55°C, whole grains, packed into capsules.

[0039] The preparation method of astragalus polysaccharide is as follows: take 100g of astragalus, add 10 times the amount of water to decoct three times, the first time for 3 hours, the second and third times for 2 hours each, combine t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com