Antibacterial treatment method of silicon surface

A treatment method and silicon surface technology, applied in medical science, prosthesis, surgery, etc., can solve the problem of reducing the biocompatibility of materials, and achieve the effect of excellent antibacterial performance and biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The antibacterial treatment method of the silicon surface of the present embodiment comprises the following steps:

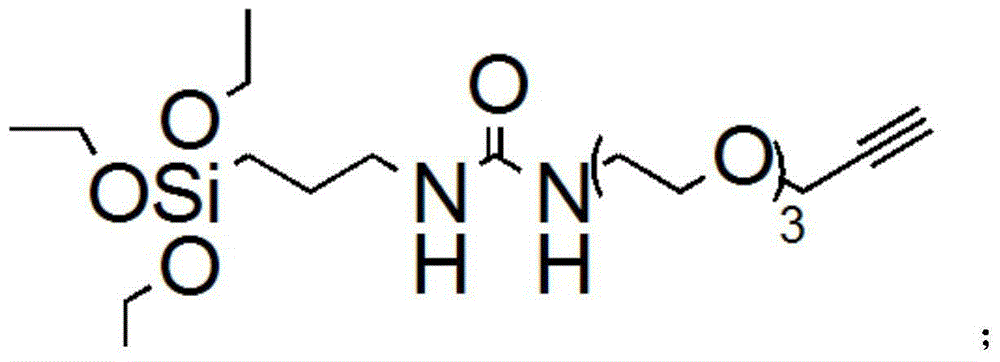

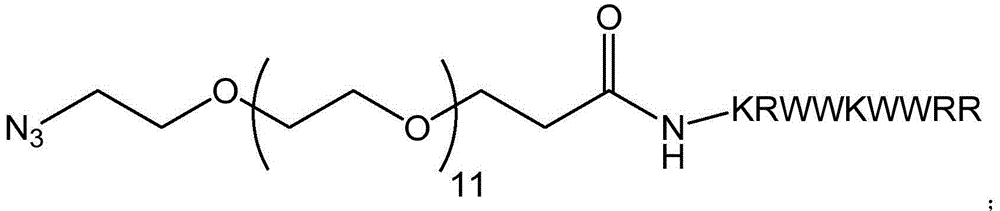

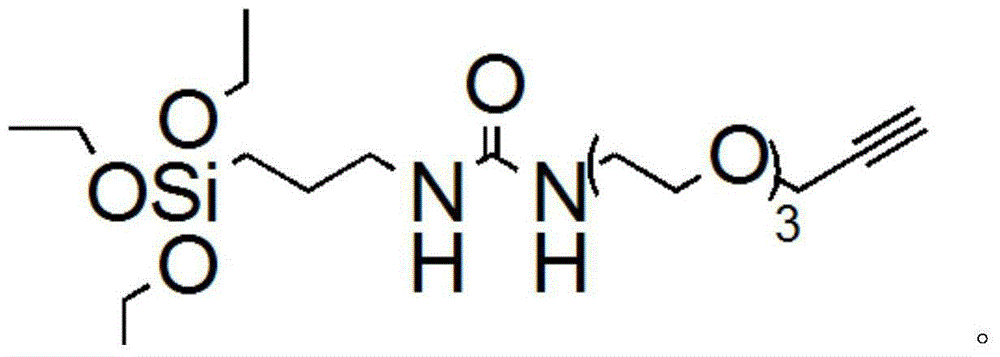

[0033] (1) Treat the surface of Si(100) with hydrofluoric acid with a volume concentration of 5% for 3 minutes; (2) use ethanol as a solvent to dissolve the silane coupling agent with an alkynyl group at a concentration of 10 mM; (3) configure Click reaction solution, which consists of: 1mM anhydrous copper sulfate, 10mM sodium ascorbate, 500μM antibacterial polypeptide KRWWKWWRR; (4) Add the click reaction solution to the silane coupling agent solution to perform a click chemical reaction, wherein the click reaction solution is mixed with silane The volume ratio of the ethanol solution of the coupling agent is 9:1, the total volume of the solution is 1mL, the reaction time is 4 hours, the temperature is 37°C, and the oxygen content in the reaction is 1ppm; (5) The solution after the reaction is spin-dried, And add the mixed solution of water and ethanol ...

Embodiment 2

[0040] The antibacterial treatment method of the silicon surface of the present embodiment comprises the following steps:

[0041] (1) Treat the surface of Si(100) with 10% hydrofluoric acid for 1 minute; (2) Use ethanol as solvent to dissolve the silane coupling agent with alkynyl groups at a concentration of 1 mM; (3) Configure the click reaction solution, It consists of: 0.5mM anhydrous copper sulfate, 5mM sodium ascorbate, 1mM antibacterial polypeptide KRWWKWWRR; (4) Add the click reaction solution to the silane coupling agent solution to perform a click chemical reaction, wherein the click reaction solution and the silane coupling agent The volume ratio of the ethanol solution is 3:1, the total volume of the solution is 1mL, the reaction time is 1 hour, the temperature is 25°C, and the oxygen content in the reaction is 2ppm; (5) spin dry the solution after the reaction, and add water and the mixed solution of ethanol to re-dissolve the product, wherein the volume ratio of...

Embodiment 3

[0046] The antibacterial treatment method of the silicon surface of the present embodiment comprises the following steps:

[0047] (1) Treat the surface of Si(100) with 8% hydrofluoric acid for 2 minutes; (2) Use ethanol as a solvent to dissolve the silane coupling agent with an alkynyl group at a concentration of 5 mM; (3) Configure the click reaction solution, It consists of: 50 μM anhydrous copper sulfate, 0.5 mM sodium ascorbate, 100 μM antibacterial polypeptide KRWWKWWRRC; (4) Add the click reaction solution to the silane coupling agent solution to perform a click chemical reaction, wherein the click reaction solution and the silane coupling agent The volume ratio of the ethanol solution is 10:1, the total volume of the solution is 1mL, the reaction time is 2 hours, the temperature is 30°C, and the oxygen content in the reaction is 1ppm; (5) spin dry the solution after the reaction, and add water and the mixed solution of ethanol to re-dissolve the product, wherein the vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com