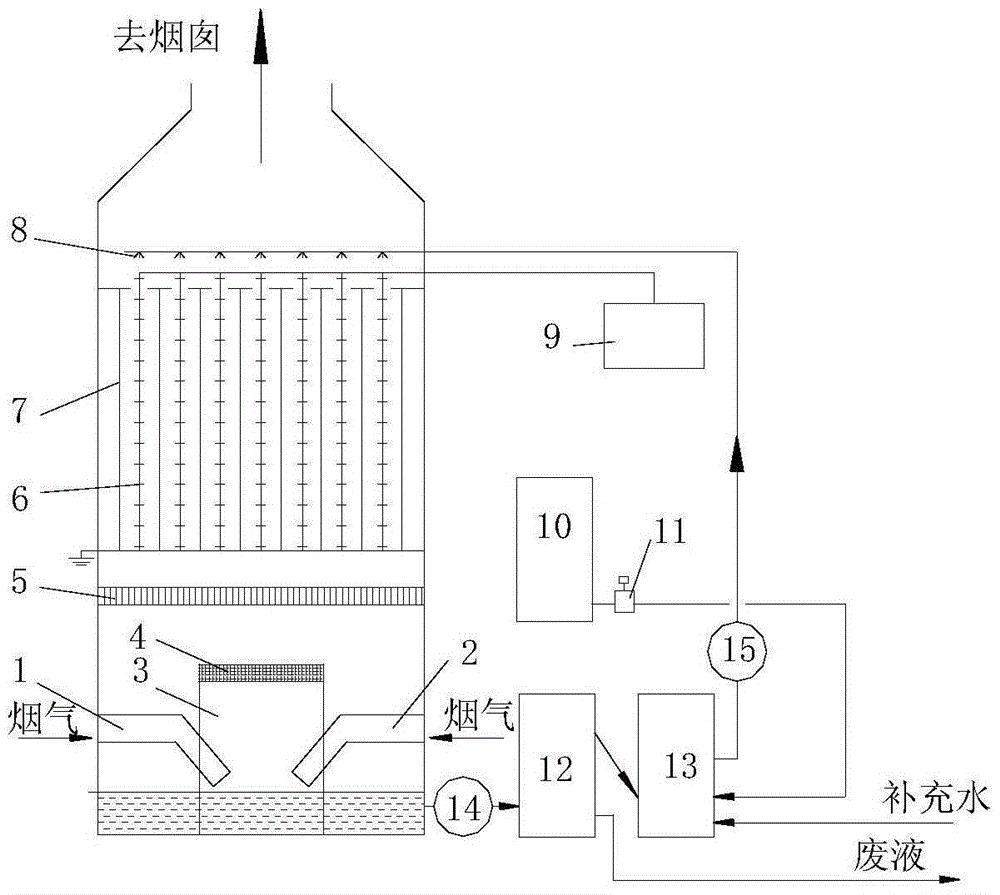

Device and method for flue gas cleaning by combining impact agglomeration wet dust collector with wet electric dust collector

A technology for wet dust collector and flue gas purification, which is applied in combined devices, chemical instruments and methods, separation methods, etc., can solve the problems of ineffective removal of submicron fine particles, achieve compact structure, improve removal efficiency, reduce The effect of operating pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] The flue gas produced by burning anthracite in the pulverized coal furnace passes through the SCR denitrification device, dry electrostatic precipitator, low temperature economizer, limestone / gypsum desulfurization tower, impact condensation wet dust collector and wet electric composite device, and chimney. The compound transposition is about 30m high and 16m in diameter; the two-way air intake pipe changes from horizontal to slanted downwards at 45° outside the impact chamber and extends into the impact chamber. The impact chamber is made of cylindrical carbon steel with a height of 12m and a diameter of 10m. The center of the inlet pipe outlet is 6m apart, and the lower end is 2m away from the liquid surface. The upper part of the wet electricity is a tubular wet electricity, and the cathode line is made of prickly wire. Flue gas parameter tests were performed at the outlet of the limestone / gypsum scrubber and at the inlet of the chimney. Tested with WJ-60B pitot tub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com