Glass melter flue gas dust removal, desulfurization and denitrification synergetic treatment system, treatment method and application

A co-processing, glass melting furnace technology, applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of poor equipment operation reliability, large investment in flue gas treatment, and difficulty in popularization and application, and achieve low operating costs. , avoid poisoning and blockage, save power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

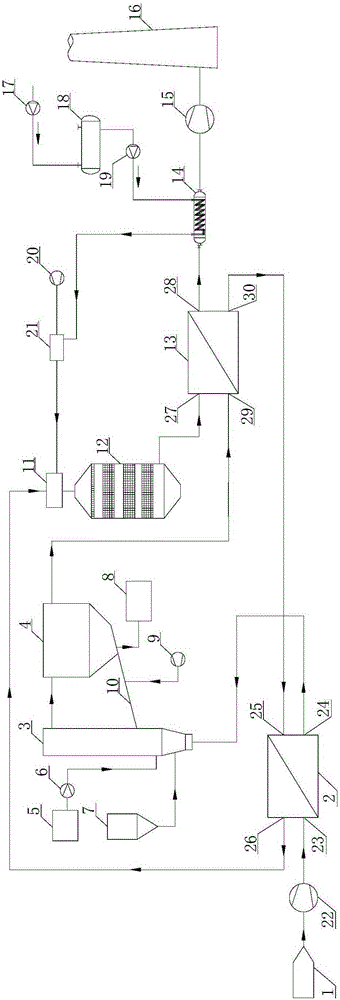

[0057] Such as figure 1 As shown, a glass melting furnace flue gas dedusting desulfurization and denitrification co-processing system includes an inlet flue 1, a first flue gas heat exchanger 2, a desulfurization tower 3, a dust collector 4, an SCR reactor 12, a second flue gas exchanger Heater 13 and ammonia supply device; Ammonia supply device comprises ammonia storage tank 18, ammonia evaporator 14, mixer 21 and ammonia injection grid 11 connected in sequence;

[0058] The inlet flue 1, the first flue gas heat exchanger 2, the desulfurization tower 3 and the dust remover 4 are sequentially connected; the dust remover 4, the second flue gas heat exchanger 13 and the first flue gas heat exchanger 2 are connected;

[0059] The first flue gas heat exchanger 2, the ammoni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com