Preparation method of remediation agent for low-concentration single-type organic pollution

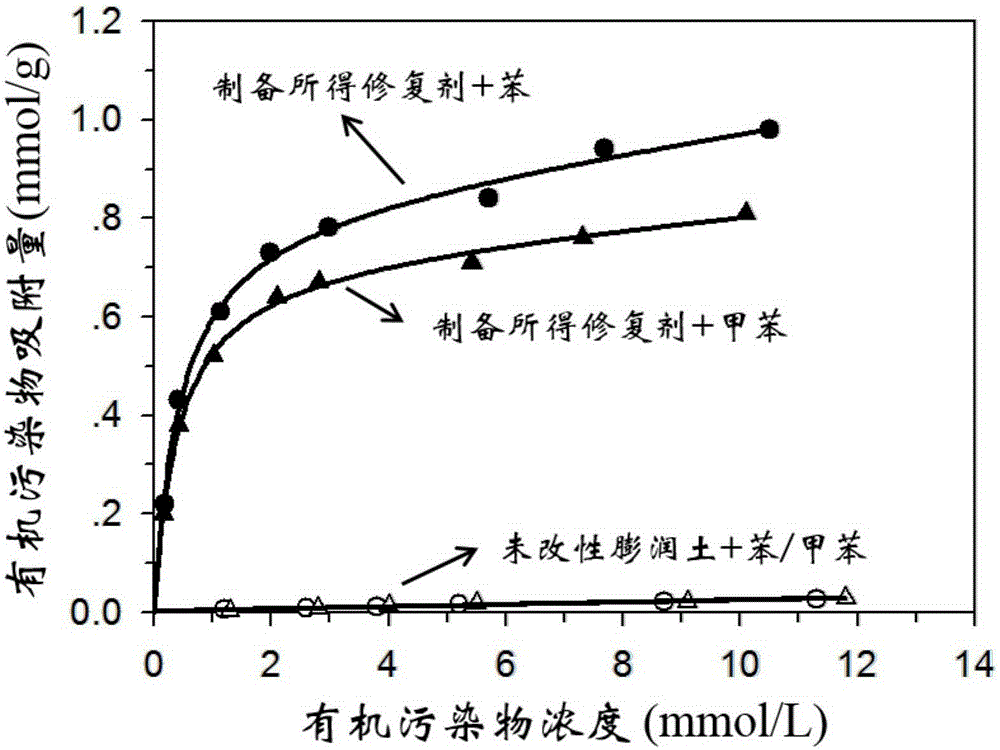

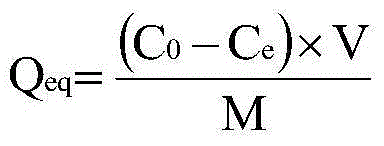

An organic pollution, low-concentration technology, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as the reduction of the ability of organic pollutants, and achieve the effects of excellent adsorption, excellent adsorption performance, and stable properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method of a low-concentration single-type organic pollution remediation agent, comprising the following steps:

[0028] a. Preparation of sodium bentonite

[0029] Add natural bentonite to excess sodium chloride solution, stir magnetically at room temperature for 24 hours, and centrifuge the solid and liquid, then rinse the bentonite with deionized water equal in volume to the sodium chloride solution for 3 consecutive times;

[0030] b. Optimization of sodium bentonite

[0031] Adding deionized water equal to the volume of the sodium chloride solution in step a to the sodium bentonite obtained in step a, separating and removing bentonite with a particle size > 2 μm by wet sedimentation, centrifuging the upper suspension and removing the supernatant, Obtain sodium bentonite with optimized particle size ≤ 2 μm;

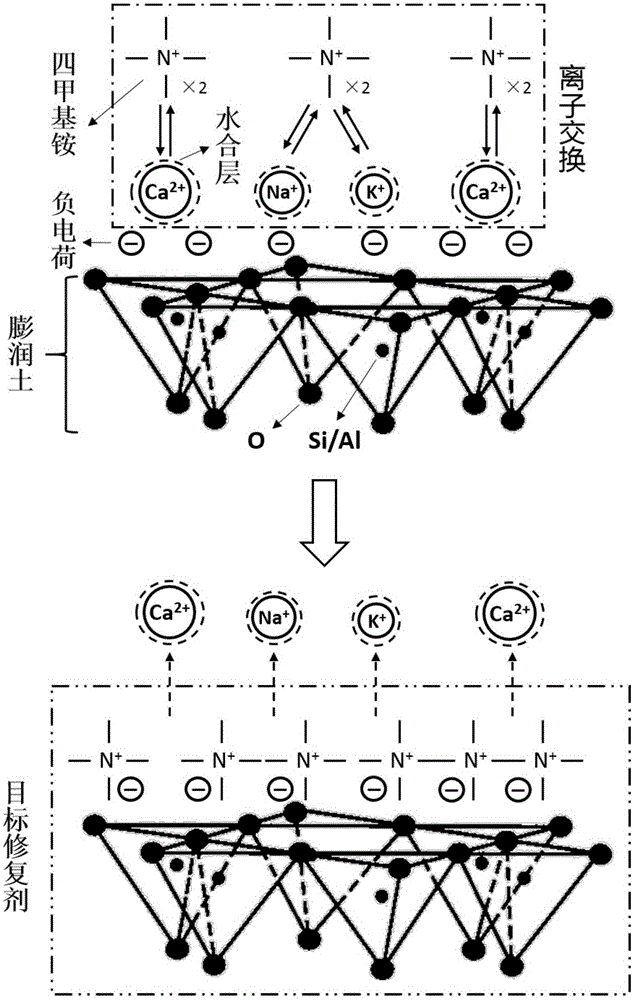

[0032] c. Modification of sodium bentonite

[0033] Add excess tetrapropylammonium bromide solution to the sodium bentonite obtained in step b,...

Embodiment 2

[0037] A preparation method of a low-concentration single-type organic pollution remediation agent, comprising the following steps:

[0038] a. Preparation of sodium bentonite

[0039] Add natural bentonite to excess sodium chloride solution, stir mechanically at room temperature for 48 hours, and after solid-liquid centrifugation, rinse bentonite with deionized water equal to the volume of sodium chloride solution for 5 consecutive times;

[0040] b. Optimization of sodium bentonite

[0041] Adding deionized water equal to the volume of the sodium chloride solution in step a to the sodium bentonite obtained in step a, separating and removing bentonite with a particle size > 2 μm by wet sedimentation, centrifuging the upper suspension and removing the supernatant, Obtain sodium bentonite with optimized particle size ≤ 2 μm;

[0042] c. Modification of sodium bentonite

[0043] Add excess tetraethylammonium bromide solution to the sodium bentonite obtained in step b, mechani...

Embodiment 3

[0047] A preparation method of a low-concentration single-type organic pollution remediation agent, comprising the following steps:

[0048] a. Preparation of sodium bentonite

[0049] Add natural bentonite to excess sodium chloride solution, mechanically stir at room temperature for at least 36 hours, and after solid-liquid centrifugation, wash the bentonite with deionized water equal to the volume of sodium chloride solution, at least 4 times in a row;

[0050] b. Optimization of sodium bentonite

[0051] Adding deionized water equal to the volume of the sodium chloride solution in step a to the sodium bentonite obtained in step a, separating and removing bentonite with a particle size > 2 μm by wet sedimentation, centrifuging the upper suspension and removing the supernatant, Obtain sodium bentonite with optimized particle size ≤ 2 μm;

[0052] c. Modification of sodium bentonite

[0053] Add excess tetramethylammonium bromide solution to the sodium bentonite obtained in s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com