Comn composite oxide catalyst for eliminating benzene series volatile organic compounds in air and preparation method thereof

A technology of volatile organic compounds and composite oxides, applied in the direction of metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of low content of active components in metal oxides Compactness, limited catalytic performance and other issues, to achieve good catalytic combustion activity of benzene-based volatile organic compounds, simple process, mild and easy-to-control conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A CoMn composite oxide catalyst for eliminating benzene series volatile organic compounds in the air, the active component of the catalyst is a CoMn spinel oxide, and the preparation method of the catalyst comprises the following steps:

[0029] (1) According to the molar ratio of citric acid: (the sum of cobalt nitrate and manganese nitrate) = 1 ~ 1.8: 1, the three are prepared into a solution, and the solution is evaporated to dryness at 80 ° C and then dried at 80 ~ 100 ° C for 12 ~24h to obtain dry material; the molar ratio between cobalt nitrate and manganese nitrate is 2~6:1;

[0030] (2) Roast the dry material obtained in step 1. The calcination condition is to raise the temperature to 300-450°C at a heating rate of 10°C / min, and then roast at a constant temperature of 300-450°C for 2.0-4.0 hours.

Embodiment 1

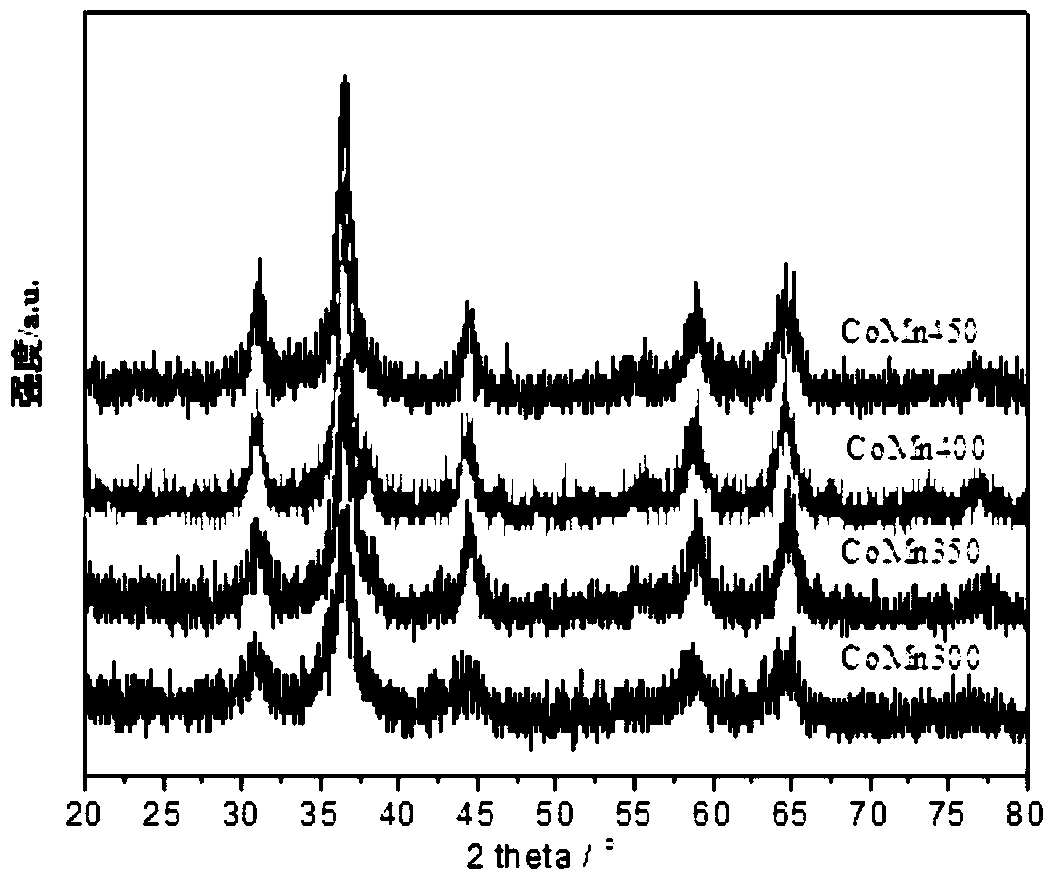

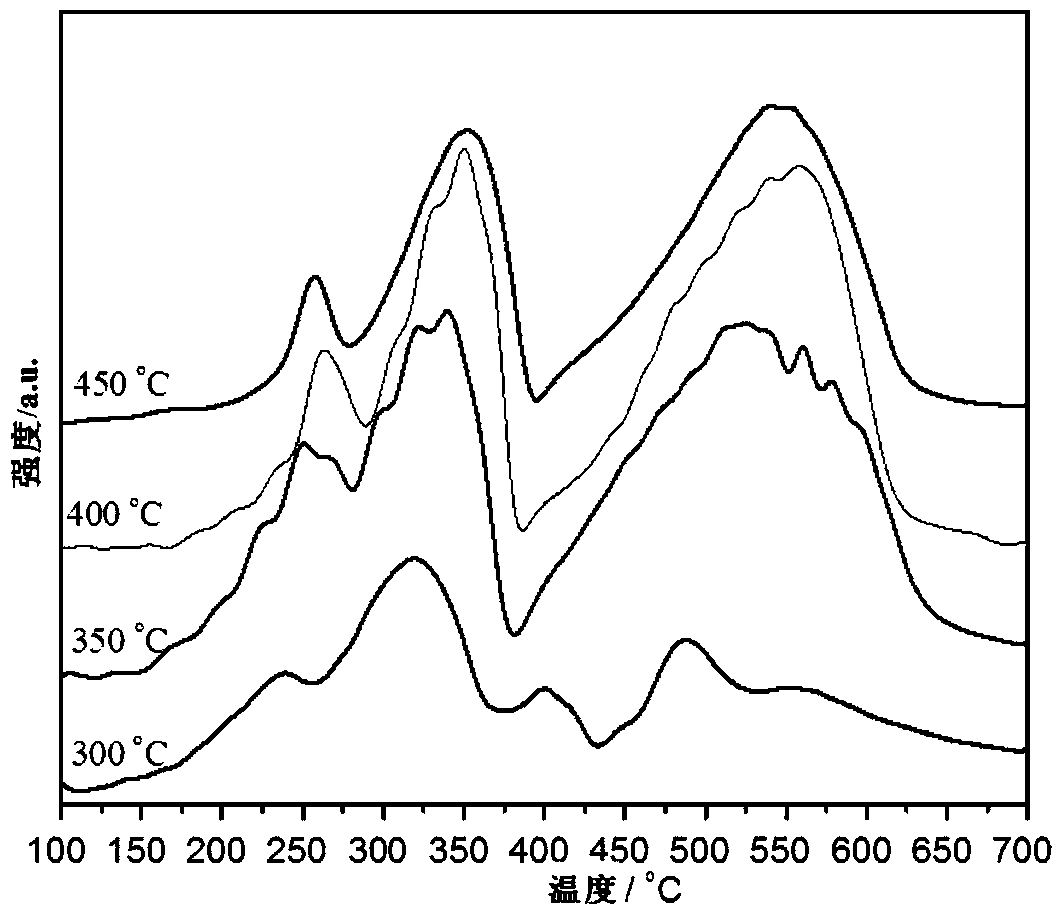

[0031] The influence of embodiment 1 calcining temperature on catalyst performance

[0032] According to the molar ratio (Co / Mn) between cobalt nitrate and manganese nitrate is 4:1, the molar ratio (CA / M, M=Co+Mn) of citric acid: (Co+Mn) is 1.5:1, the roasting temperature 300, 350, 400, 450°C, roasting time 3h, prepare CoMn composite oxide catalyst, use the catalyst in the catalytic combustion of toluene, and evaluate the activity of the catalyst; It is carried out in a fixed-bed reactor, and a thermocouple is built in the reactor, and the reaction temperature is determined by The micro-reactor is placed in a tube furnace; the toluene waste gas includes: 1.0% toluene and 99.0% air by volume percentage; the specific operation steps are as follows:

[0033] Measure 50 mg of catalyst and pack it into the reaction tube of the microtubular fixed-bed reactor, heat up to the reaction temperature, and feed the toluene waste gas of the composition, at the reaction temperature and 66,...

Embodiment 2

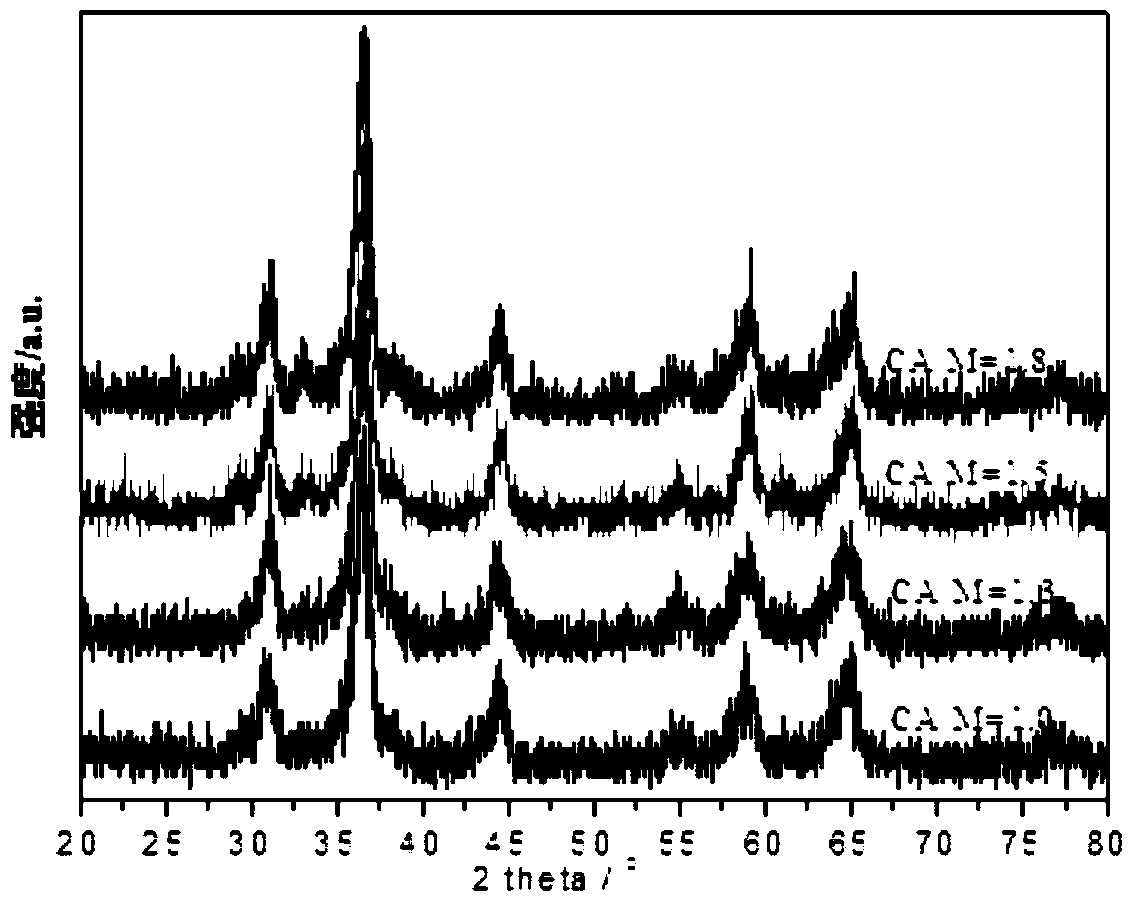

[0040] Embodiment 2 citric acid: the influence of the mol ratio (CA / M, M=Co+Mn) of (Co+Mn) on catalyst performance

[0041] Under the condition that the molar ratio (Co / Mn) between cobalt nitrate and manganese nitrate is 4:1, the calcination temperature is 350°C, and the calcination time is 3.0h, different citric acid: (Co+Mn) molar ratios are set, A CoMn composite oxide catalyst was prepared, and the catalyst was used for catalytic combustion of toluene, and the activity evaluation of the catalyst was carried out. The activity evaluation method was the same as in Example 1.

[0042] The results of the catalytic combustion conversion rate of benzene series volatile organic compounds obtained by the above-mentioned catalyst activity evaluation experiment of the CoMn composite oxide catalyst are shown in Table 2:

[0043] Table 2 citric acid: the influence of the molar ratio (CA / M(M=Co+Mn)) of (Co+Mn) on the catalytic combustion performance of toluene

[0044]

[0045] It ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com