Edge-controlling rolling method for wide magnesium alloy plate

A magnesium alloy and plate technology, applied in the direction of contour control, etc., can solve the problems of low fracture toughness of magnesium alloy materials, lack of effective replenishment of vacancies, and limited metal flow, so as to improve mechanical properties, eliminate edge cracks, and weaken various parts. The effect of anisotropic defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The billet is AZ31B magnesium alloy ingot, the specifications are: thickness × width × length = 360mm × 1000mm × 1500mm, the rolling mill equipment is a four-high rolling mill, the work roll: ?700mm × 2400mm, and the finished product after rolling: thickness × width = 50mm × 2000mm.

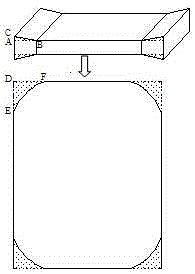

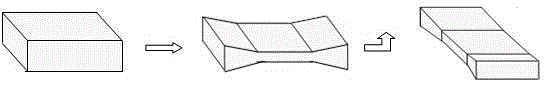

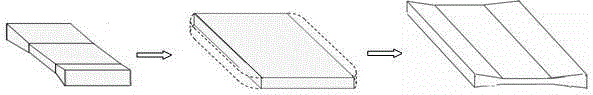

[0021] According to the method of the present invention: at first determine the prefabricated cross-rolling edge portion convexity, according to the established rolling mill work roll specification, get =2000mm, for the material of magnesium alloy AZ31, the specifications of the billet and the dimension after rolling, take =335, from formula (2): 55mm, =364mm, =110mm, the prefabricated cross-rolled edge convexity can be completed according to the process shown in Figure 2(a); then the rolled piece that has been rotated by 90° is subjected to edge-controlled widening rolling, and two passes are carried out in total. The first pass After production, the width of the original billet i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com