Plunger self-locking metal corrugated pipe multi-corrugate water expansion once-forming machine

A metal bellows and molding machine technology, applied in molding tools, metal processing equipment, manufacturing tools, etc., can solve the problems of inability to process wave number bellows at one time, poor quality of finished products, low clamping force, etc., and achieve fitting Tightness, good quality of finished products, and the effect of improving clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Through the following description of the embodiments, it will be more helpful for the public to understand the present invention, but the specific embodiments given by the applicant cannot and should not be regarded as limitations on the technical solutions of the present invention, any components or technical features Changes to the definition and / or formal but not substantive changes to the overall structure should be regarded as the scope of protection defined by the technical solutions of the present invention.

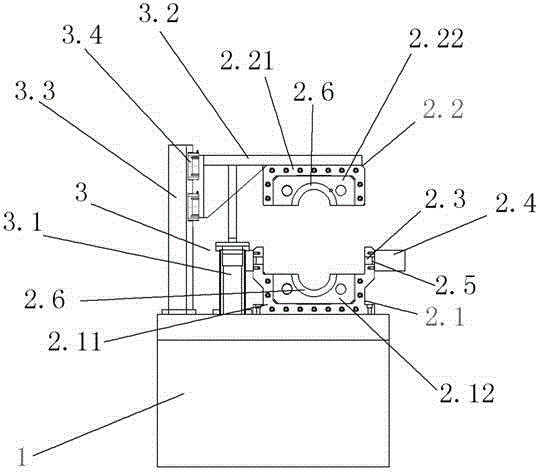

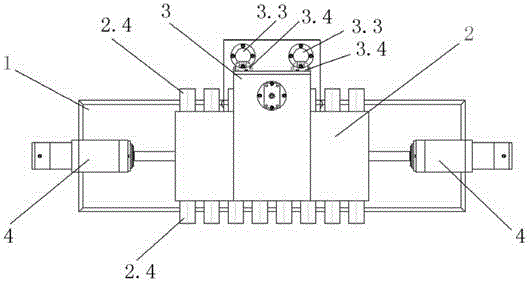

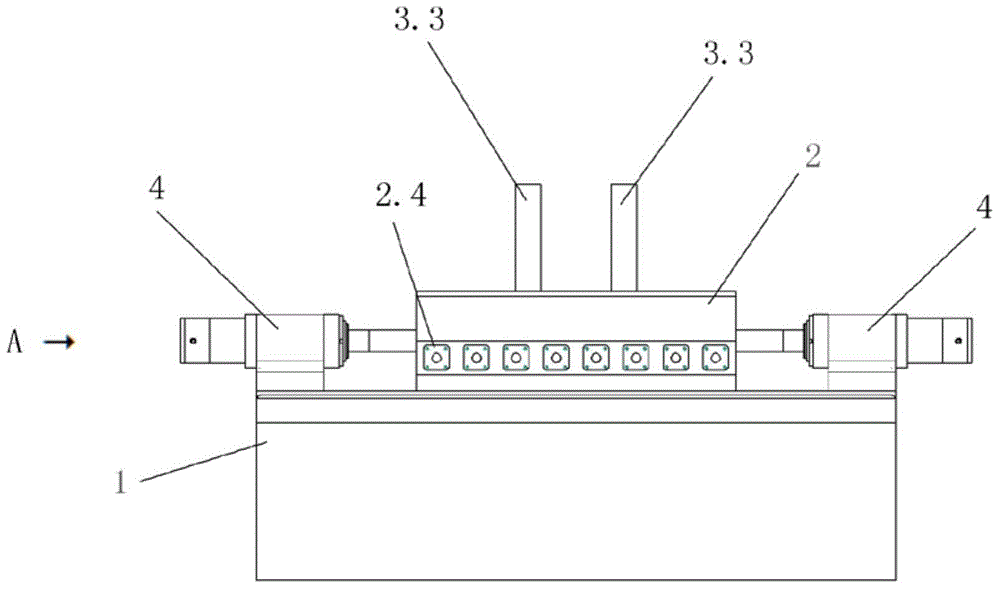

[0021] This embodiment provides a plunger self-locking metal bellows multi-wave water swelling one-time forming machine, such as Figure 1-4 As shown, it includes an operating table 1, a molding die 2, a mold opening and closing mechanism 3, and two axial pressing cylinders 4 respectively arranged on both sides of the molding die 2.

[0022] The forming mold 2 , the mold opening and closing mechanism 3 , and the axial pressing oil cylinder 4 are all arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com