Thermosetting resin sandwich preimpregnation body and preparation method thereof, and copper-clad plate

A thermosetting, prepreg technology, used in chemical instruments and methods, synthetic resin layered products, thermoplastic polymer dielectrics, etc., can solve problems such as increasing production costs, improve insulation, improve adhesion, and improve uniformity. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

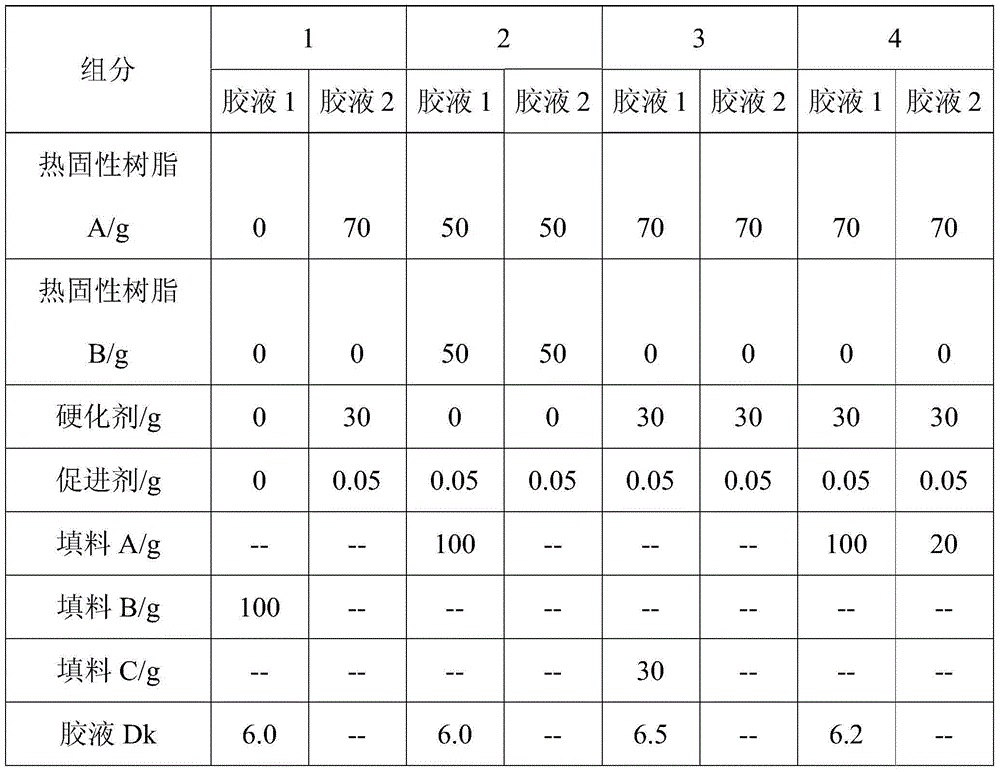

[0049] The composition of the solid ingredients of Examples 1-4 is shown in Table 1, and methyl ethyl ketone is used to prepare the thermosetting epoxy resin varnish used in the manufacture of copper clad laminates, in which the solid content accounts for 65%.

[0050] The copper clad substrates of Examples 1-4 were prepared according to the following preparation process:

[0051] (1) Glue making: add the solvent to the batching container, add thermosetting resin, curing agent solution and curing accelerator solution separately under stirring; after stirring for 2 hours, add fillers, continue stirring for 4-8 hours, sample the glue solution The gel time (170°C constant temperature hot plate) is 200-300 seconds.

[0052] (2) Impregnation: The reinforced material layer impregnated with glue 1 and glue 2 is passed through a vertical or horizontal impregnation machine, and the sandwich prefabricated is prepared by controlling the extrusion wheel speed, line speed, air temperature and fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com