A kind of firing process of light-weight insulating brick

An insulating brick, light-weight technology, applied in the field of insulating materials, can solve the problems of long time consumption and complicated firing process, and achieve the effect of simple firing process, improving plasticity and ensuring compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

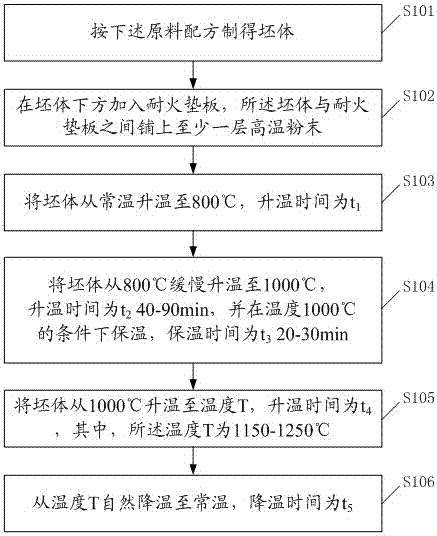

[0085] (1) Mix the raw materials according to the ratio. The formula is: 60% industrial cinder, 20% mud, 4% potassium feldspar, 4% albite feldspar, 4% quartz, and 8% polishing slag; then ball milling, spraying, and pressing Forming and drying to obtain a green body;

[0086] (2) Add a refractory backing plate under the green body, and spread at least one layer of alumina high-temperature powder between the green body and the refractory backing plate;

[0087] (3) Raise the green body from room temperature to 800°C, and the heating time is t 1 =20min;

[0088] (4) Slowly raise the temperature of the green body from 800°C to 1000°C, and the heating time is t 2 =40min, and heat preservation under the condition of temperature 1000℃, the heat preservation time is t 3 =20min;

[0089] (5) Raise the green body from 1000°C to temperature T, wherein the temperature T is 1150°C, and the heating time is t 4 =40min;

[0090] (6) Naturally cool down from temperature T to normal temp...

Embodiment 2

[0093] (1) Mix the raw materials according to the ratio. The formula is: 65% industrial cinder, 10% mud, 5% potassium feldspar, 5% albite feldspar, 5% quartz, and 10% polishing slag; then ball milling, spraying, and pressing Forming and drying to obtain a green body;

[0094] (2) Add a refractory backing plate under the green body, and spread at least one layer of high-temperature silica powder between the green body and the refractory backing plate;

[0095] (3) Raise the green body from room temperature to 800°C, and the heating time is t 1 =30min;

[0096] (4) Slowly raise the temperature of the green body from 800°C to 1000°C, and the heating time is t 2 =50min, and heat preservation under the condition of temperature 1000℃, the heat preservation time is t 3 =25min;

[0097] (5) Raise the green body from 1000°C to temperature T, wherein the temperature T is 1200°C, and the heating time is t 4 =50min;

[0098] (6) Naturally cool down from temperature T to normal temp...

Embodiment 3

[0101] (1) Mix the raw materials according to the ratio, the formula is: 70% industrial cinder, 6% mud, 6% potassium feldspar, 6% albite feldspar, 6% quartz, 6% polishing slag; then ball milling, spraying, pressing Forming and drying to obtain a green body;

[0102] (2) Add a refractory backing plate under the green body, and spread at least one layer of alumina high-temperature powder between the green body and the refractory backing plate;

[0103] (3) Raise the green body from room temperature to 800°C, and the heating time is t 1=40min;

[0104] (4) Slowly raise the temperature of the green body from 800°C to 1000°C, and the heating time is t 2 =60min, and heat preservation under the condition of temperature 1000℃, the heat preservation time is t 3 =30min;

[0105] (5) Raise the green body from 1000°C to temperature T, wherein the temperature T is 1180°C, and the heating time is t 4 =50min;

[0106] (6) Naturally cool down from temperature T to normal temperature, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com