Method for preparing tanshinone IIA chemical reference substance from Salvia prattii

A technology of Kangding sage and tanshinone, which is applied in the field of preparation of tanshinone IIA chemical reference substances, can solve the problems of large loss and complicated process in the crystallization process, and achieve the effects of high recovery rate, simple process and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

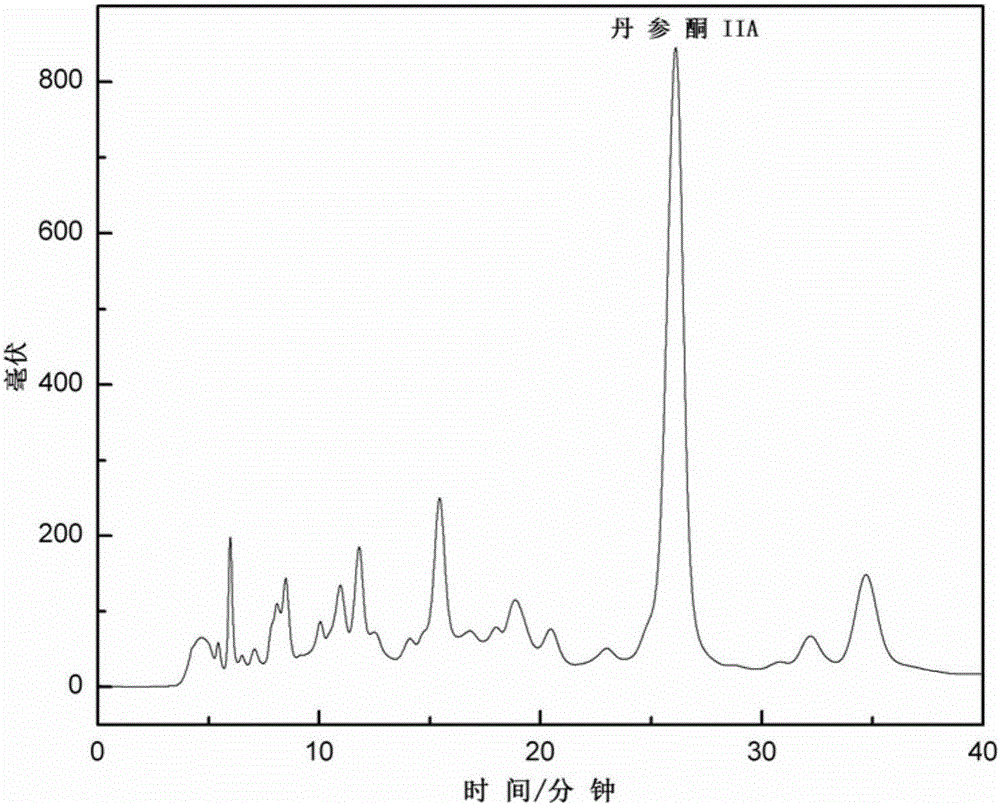

[0028] A method for preparing tanshinone IIA chemical reference substance in Kangding sage, comprising the following steps:

[0029] ⑴ Silica gel column enrichment:

[0030] Separation of 1.0 Kg of the ethanol extract of Sage Kangding in the form of brownish red extract prepared by conventional methods through silica gel column chromatography: eluting with 5 times the column volume of chloroform solvent, collecting the chloroform eluate and drying under reduced pressure To obtain 26.4 g of crude sample rich in tanshinone IIA in red powder form;

[0031] in:

[0032] The conditions of decompression drying refer to a vacuum degree of 0.06MPa and a temperature of 70°C;

[0033] Silica gel column refers to column chromatography silica gel equipped with 100-200 mesh.

[0034] ⑵Microporous resin impurity removal:

[0035] The crude sample rich in tanshinone IIA was dissolved with 100% methanol, filtered to obtain filtrate A, separated on a microporous resin column on the filtrat...

Embodiment 2

[0046] A method for preparing tanshinone IIA chemical reference substance in Kangding sage, comprising the following steps:

[0047] ⑴ Silica gel column enrichment:

[0048] Separation of 0.5 Kg of the ethanol extract of Sage Kangding in the form of brownish red extract prepared by a conventional method through silica gel column chromatography: eluting with 10 times the column volume of chloroform solvent, collecting the chloroform eluate and drying under reduced pressure To obtain 13.5 g of crude sample rich in tanshinone IIA in red powder form;

[0049] in:

[0050] The conditions of decompression drying refer to a vacuum degree of 0.09MPa and a temperature of 50°C;

[0051] Silica gel column refers to column chromatography silica gel equipped with 100-200 mesh.

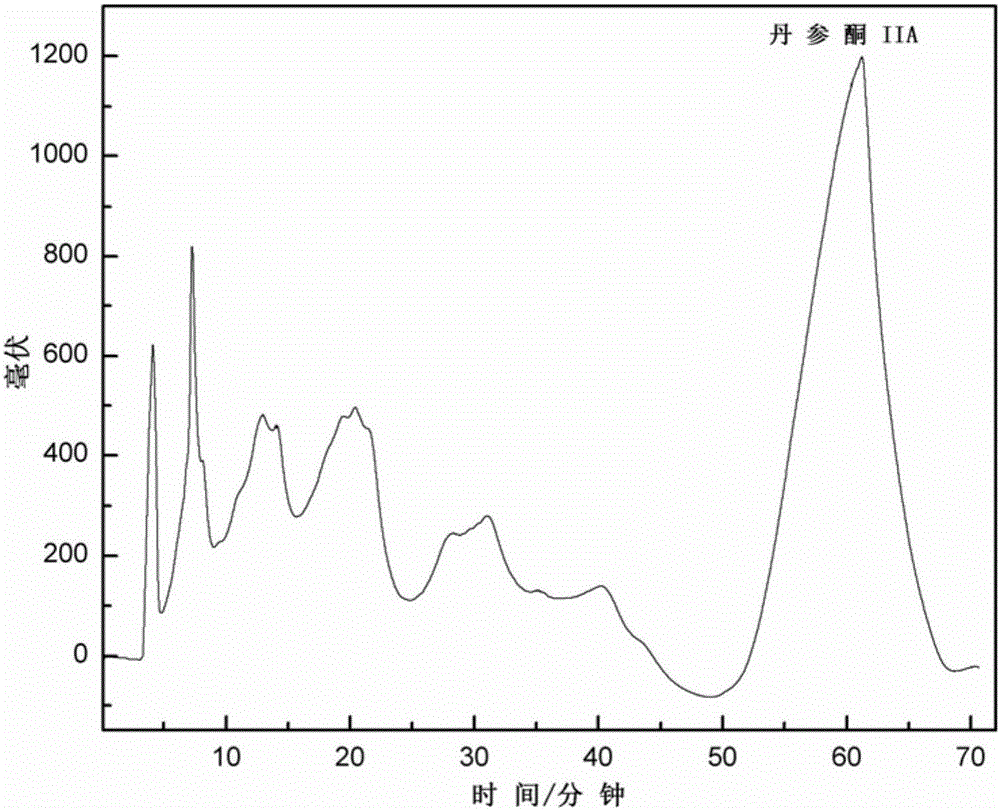

[0052] ⑵Microporous resin impurity removal:

[0053] The crude sample rich in tanshinone IIA was dissolved with 100% methanol, filtered to obtain filtrate A, separated on a microporous resin column on the filtr...

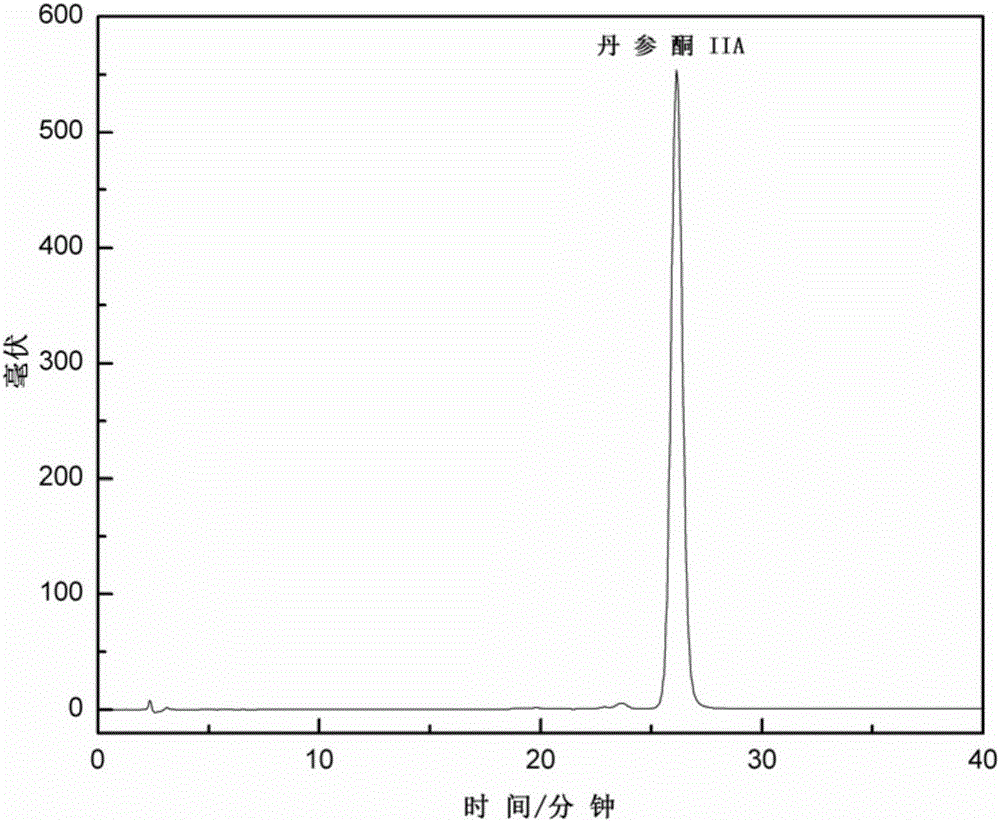

Embodiment 3

[0064] A method for preparing tanshinone IIA chemical reference substance in Kangding sage, comprising the following steps:

[0065] ⑴ Silica gel column enrichment:

[0066] Separation of 2.0 Kg of the alcohol extract of Sage Kangding in the form of brownish red extract prepared by conventional methods through silica gel column chromatography: eluting with chloroform solvent of 8 times the column volume, collecting the chloroform eluate and drying under reduced pressure To obtain 51.9 g of crude sample rich in tanshinone IIA in red powder form;

[0067] in:

[0068] The conditions of decompression drying refer to a vacuum degree of 0.07MPa and a temperature of 60°C;

[0069] Silica gel column refers to column chromatography silica gel equipped with 100-200 mesh.

[0070] ⑵Microporous resin impurity removal:

[0071] The crude sample rich in tanshinone IIA was dissolved with 95% methanol, and filtrate A was obtained by filtration. The filtrate A was separated on a microporo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com