Water-based acrylic painting pigment and preparation method thereof

A technology of acrylic and painting, applied in the field of pigments, can solve the problems of hydrolysis and softening of paint film on the surface of paintings, contact adhesion, etc., and achieve the effects of avoiding mutual adhesion, increasing fluid volume, good water retention and fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

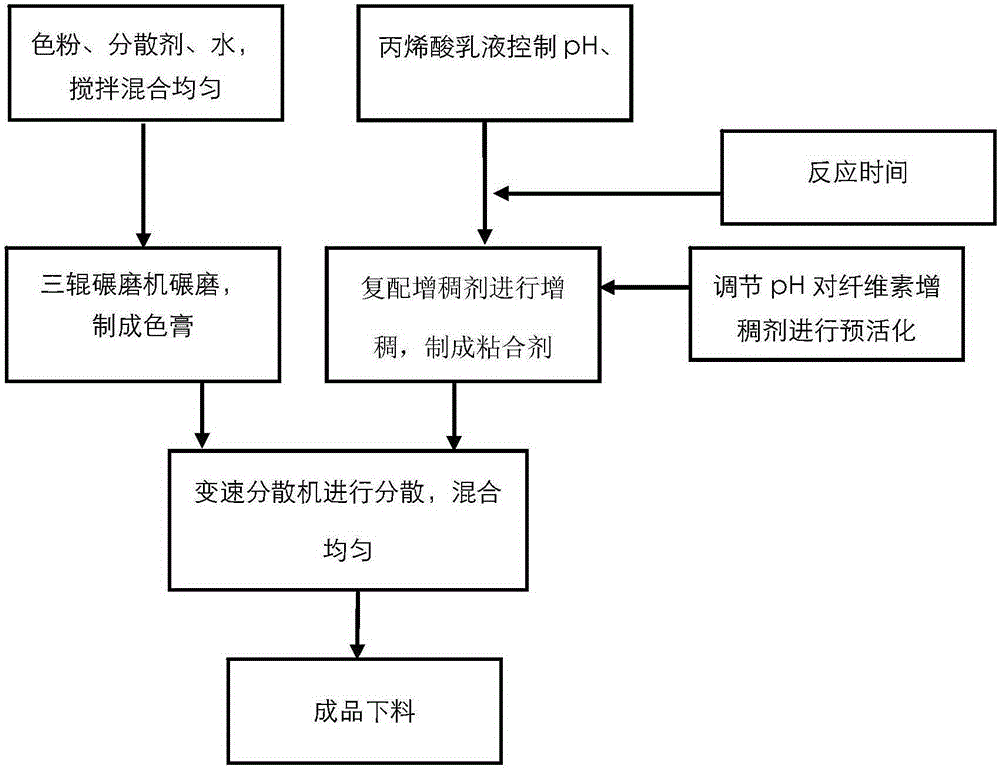

[0044] The present invention also discloses a preparation method of the above-mentioned water-based acrylic paint, comprising the following steps:

[0045] (A) Mix 10-15 parts by weight of toner, 0.2-0.4 parts by weight of dispersant and 15-20 parts by weight of water, and make a color paste after grinding;

[0046] (B) mixing hydroxycellulose and an alkali-soluble thickener to obtain a thickener;

[0047] Mix 40-50 parts of acrylic emulsion with 5-10 parts by weight of the thickener, adjust the pH value to 8-9, and obtain an adhesive after reaction;

[0048](C) mixing the color paste and adhesive to obtain water-based acrylic paint.

[0049] According to the present invention, the selection and addition amount of each component is as described in the technical solution above, and will not be repeated here.

[0050] First, 10-15 parts by weight of toner, 0.2-0.4 parts by weight of dispersant and 15-20 parts by weight of water are uniformly mixed, and the color paste is prepa...

Embodiment 1

[0058] The solid acrylic resin is mixed with ammonia water, and the pH value is adjusted to 8 until the solid acrylic resin is completely dissolved, wherein the mass percentage of the solid acrylic resin is 30%.

[0059] Mix 10 parts by weight of toner, 0.2 parts by weight of dispersant and 15 parts by weight of water evenly, and make a color paste after grinding to a particle size of 35 μm;

[0060] Mixing hydroxyethyl cellulose and an alkali-soluble thickener according to a mass ratio of 3:2 to obtain a thickener;

[0061] Mix 40 parts of acrylic emulsion and 5 parts of the thickener, adjust the pH value to 8-9, and obtain the adhesive after reaction;

[0062] The color paste and the adhesive are mixed evenly to obtain the water-based acrylic paint.

[0063] After diluting the water-based acrylic paint prepared in this embodiment 3 times with water, coat it on the drawing paper with a 120 μm applicator. Layer contact), press 20kg of gravity, and check whether the coating i...

Embodiment 2

[0066] Mix the solid acrylic resin with ammonia water, adjust the pH value to 8, until the solid acrylic resin is completely dissolved, wherein the mass percentage of the solid acrylic resin is 32%.

[0067] Mix 13 parts by weight of toner, 0.3 parts by weight of dispersant and 18 parts by weight of water evenly, and make a color paste after grinding to a particle size of 30 μm;

[0068] Mixing hydroxyethyl cellulose and an alkali-soluble thickener according to a mass ratio of 5:1 to obtain a thickener;

[0069] Mix 45 parts of acrylic emulsion and 8 parts of the thickener, adjust the pH value to 8-9, and obtain the adhesive after reaction;

[0070] The color paste and the adhesive are mixed evenly to obtain the water-based acrylic paint.

[0071] After diluting the water-based acrylic paint prepared in this embodiment 3 times with water, coat it on the drawing paper with a 120 μm applicator, the area of painting is 7㎡ / kg, and fold it in half after the coating is dried and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com