Water-based double-component anti-doodling paint

A two-component coating and anti-graffiti technology, applied in anti-fouling/underwater coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problem of low surface energy of anti-graffiti coatings, affecting the appearance of buildings, and solvent poisoning and explosion To improve the uniformity of the paint film, improve the self-cleaning effect, and prolong the life of the paint film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] A kind of anti-graffiti coating, described anti-graffiti coating is the two-component coating that is made up of A component and B component:

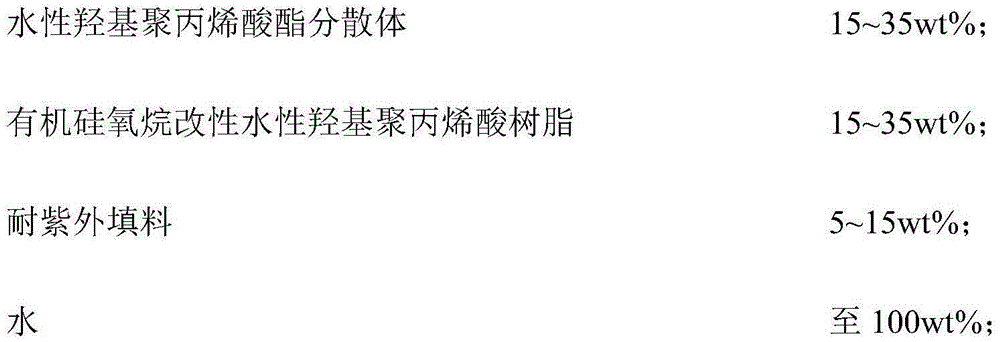

[0061] Wherein, A component comprises following components by weight percentage:

[0062]

[0063] Wherein, the B component comprises the following components by weight percentage:

[0064] Hydrophilic modified aliphatic polyisocyanate curing agent 60wt%;

[0065] Solvent to 100wt%.

Embodiment 2

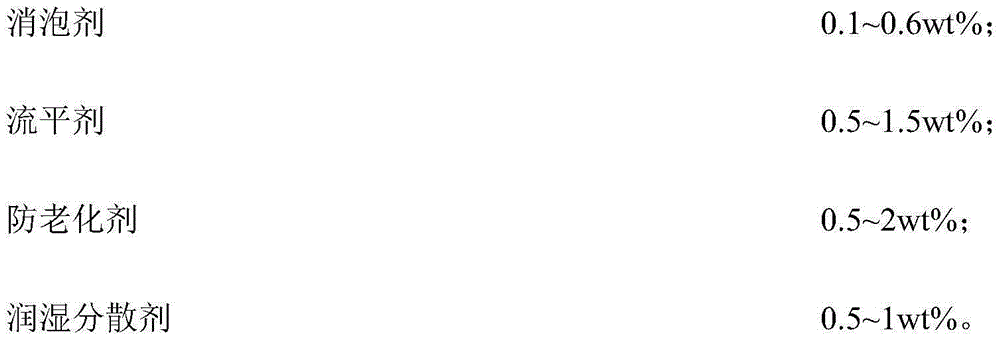

[0067] A kind of antigraffiti coating, described antigraffiti coating is the two-component coating that is made up of A component and B component: wherein, A component comprises following component by weight percentage:

[0068]

[0069]

[0070] Wherein, the B component comprises the following components by weight percentage:

[0071] Hydrophilic modified aliphatic polyisocyanate curing agent 80wt%;

[0072] Solvent to 100wt%.

Embodiment 3

[0074] A kind of anti-graffiti coating, described anti-graffiti coating is the two-component coating that is made up of A component and B component:

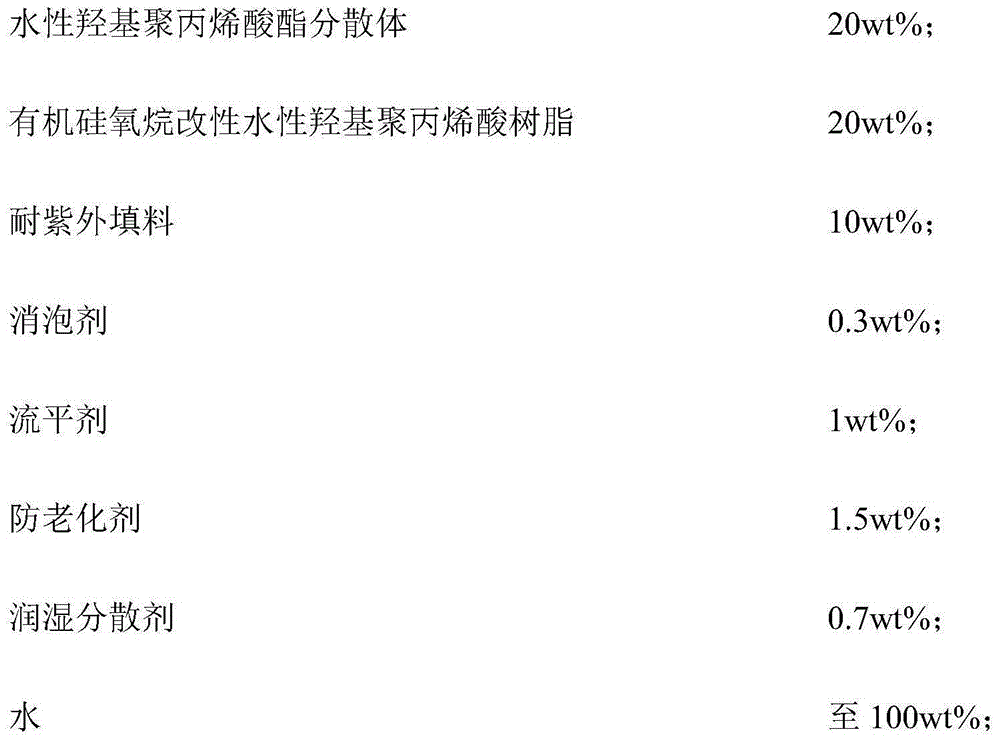

[0075] Wherein, A component comprises following components by weight percentage:

[0076]

[0077] Wherein, the B component comprises the following components by weight percentage:

[0078] Hydrophilic modified aliphatic polyisocyanate curing agent 70wt%;

[0079] Solvent to 100wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com