Tubular conjugated microporous polymer-based phase-change composite energy-storage materials and preparation method thereof

A composite energy storage material and conjugated microporous technology, which is applied in the direction of heat exchange materials, chemical instruments and methods, etc., to achieve the effects of being beneficial to energy storage and sustainable development, enhancing thermal stability, and improving thermal storage performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] A method for preparing a tubular conjugated microporous polymer phase-change composite energy storage material, the steps of which are:

[0020] (1) Preparation of tubular conjugated microporous polymer CMPN-1: add toluene and triethylamine into the container at a ratio of 0.8:1~1.2:1, replace with nitrogen for 15~30min, and then replace with 3:1~ 5:2 Weigh 1,3,5-tris(4-bromophenyl)benzene and 1,4-diethynylbenzene into the container, weigh palladium (0) and copper iodide according to 10:3~8:4 and add Stir the container evenly, slowly raise the temperature to 70~80°C, keep the reaction in the dark for 12~24h, then stop the reaction, cool to 20~30°C, wash with chloroform, acetone, water and methanol in sequence, and wash the sample with Wrap in filter paper, perform Soxhlet extraction with methanol for 48-72 hours, and then dry at 60-70°C;

[0021] (2) Preparation of tubular conjugated microporous polymer CMPN-2: add toluene and triethylamine into the container at a rati...

Embodiment 1

[0030] The present invention uses tubular conjugated microporous polymers CMPN-1, CMPN-2 and CMPN-3 as carriers in phase-change composite energy storage materials, and the steps are as follows:

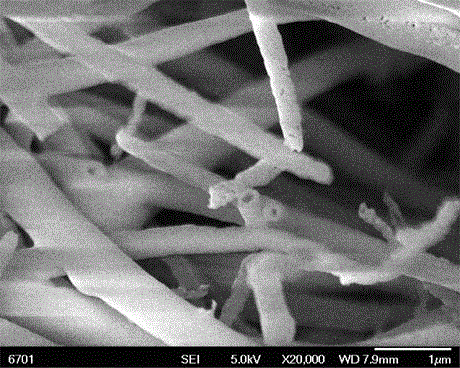

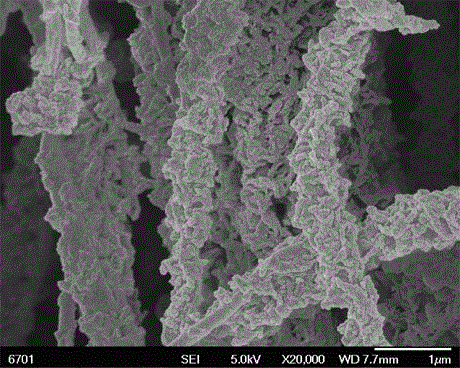

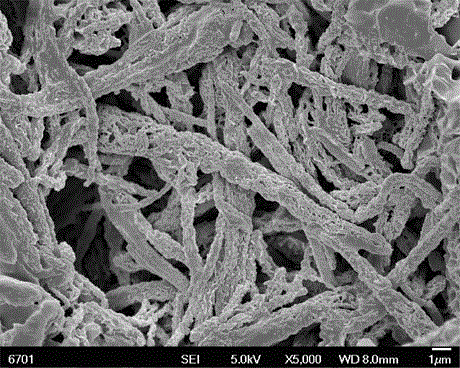

[0031] (1) Preparation of tubular conjugated microporous polymer CMPN-1: Measure 5ml each of toluene and triethylamine into the container, replace with nitrogen for 20min, weigh 1,3,5-tris(4-bromo Add 543mg of phenyl)benzene and 283.5mg of 1,4-diethynylbenzene into the container, weigh 100mg of palladium (0) and 30mg of copper iodide into the container, stir evenly, slowly raise the temperature to 80°C, keep the reaction in the dark for 24h, and then stop React, cool to room temperature, wash with chloroform, acetone, water and methanol successively, wrap the washed sample with filter paper, carry out Soxhlet extraction with methanol for 72 hours, and then dry at 70°C to obtain tubular conjugated microparticles The pore polymer CMPN-1, composed of figure 1 with Figure 4 The specifi...

Embodiment 2

[0038] (1) Preparation of tubular conjugated microporous polymer CMPN-1: Measure 5ml each of toluene and triethylamine into the container, replace with nitrogen for 20min, weigh 1,3,5-tris(4-bromo Add 543mg of phenyl)benzene and 283.5mg of 1,4-diethynylbenzene into the container, weigh 100mg of palladium (0) and 30mg of copper iodide into the container, stir evenly, slowly raise the temperature to 80°C, keep the reaction in the dark for 24h, and then stop React, cool to room temperature, wash with chloroform, acetone, water and methanol successively, wrap the washed sample with filter paper, carry out Soxhlet extraction with methanol for 72 hours, and then dry at 70°C to obtain tubular conjugated microparticles The pore polymer CMPN-1, composed of figure 1 with Figure 4 The specific morphology of the tubular conjugated microporous polymer CMPN-1 can be seen;

[0039] (2) Preparation of tubular conjugated microporous polymer CMPN-2: Measure 5ml each of toluene and triethylam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com