Cu-Fe alloy wire and preparing method thereof

A copper-iron alloy and wire technology, applied in the field of copper-iron alloy wire and its preparation, can solve problems such as hindering the production and application of Cu-Fe alloy, and achieve excellent electromagnetic shielding effect, stable performance and stable chemical composition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

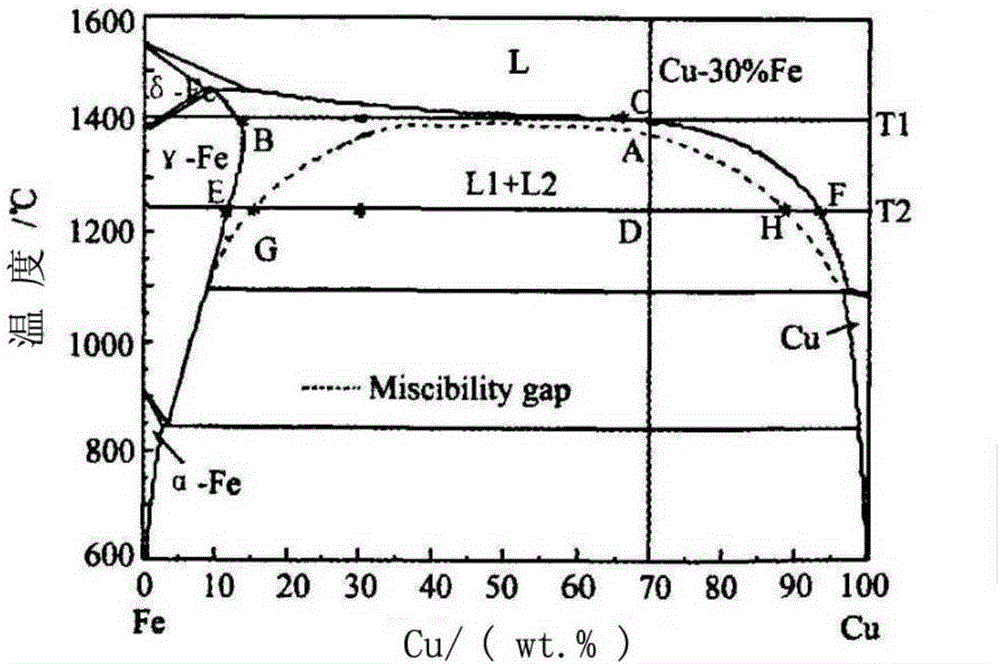

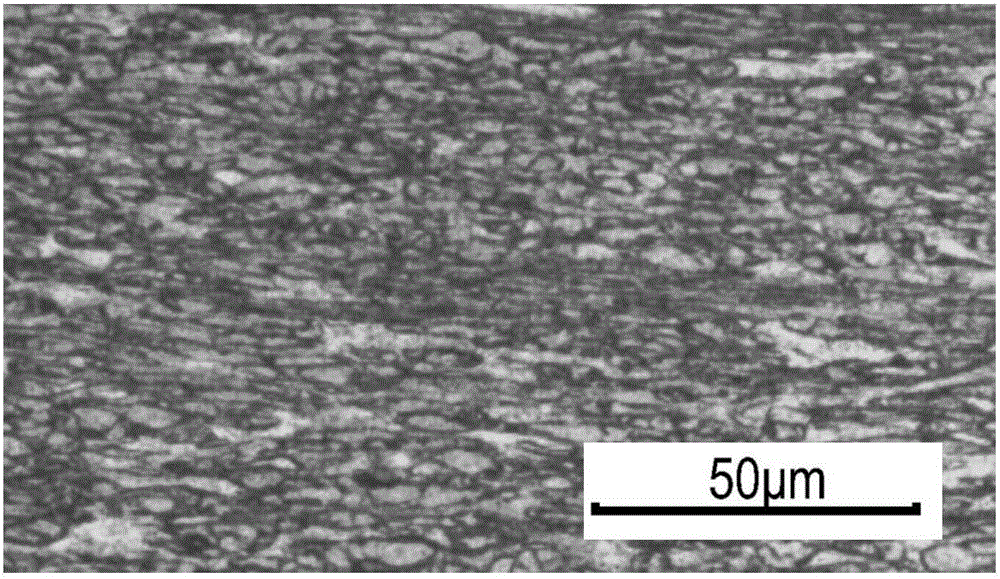

[0080] 1. The specific consumption of each raw material for preparing the copper-iron master alloy masterbatch in this embodiment is (wt.%): Fe=48%; Ni=0.25%; La=0.02%; Ce=0.04%; Cu=51.69%; The composition of the master alloy masterbatch (1#) is shown in Table 1, and the metallographic microscopic morphology of the master alloy is shown in figure 2 ,Depend on figure 2 It can be seen from the data in Table 1 that the chemical composition of the copper-iron master alloy prepared by the present invention is stable, and the composition of the upper, middle and lower parts of the ingot is uniform; the Fe element is evenly distributed in the master alloy without segregation.

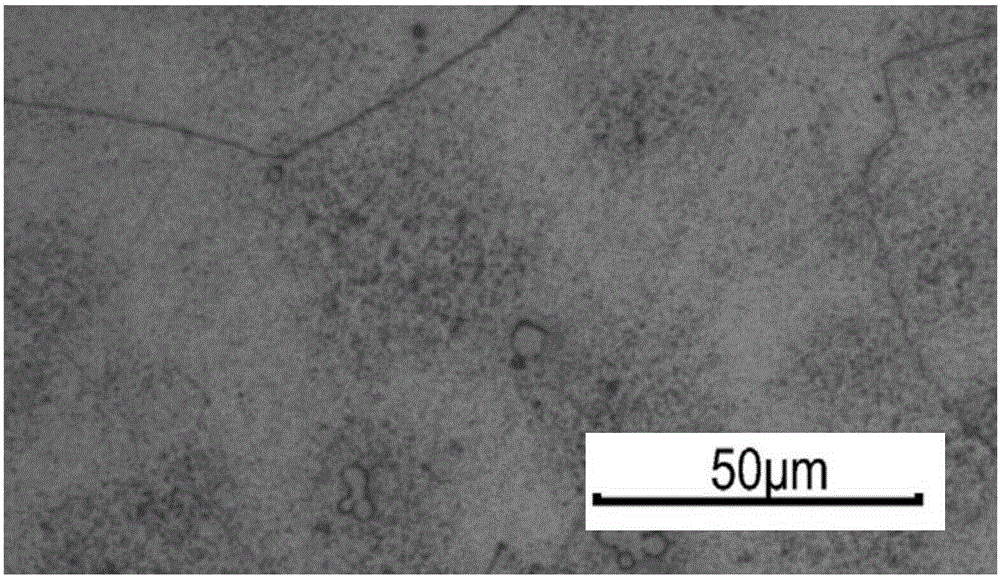

[0081] 2. Prepare high-strength and high-ductility CuFe alloy, the chemical composition is designed as (wt.%): Fe=8.8%, Cu=91.2%. The composition of the prepared copper-iron alloy ingot is shown in Table 2. The chemical composition of the ingot is stable, and the composition of the upper, middle and lower p...

Embodiment 2

[0084] 1. The process of preparing the copper-iron master alloy masterbatch in this embodiment is the same as in embodiment 1.

[0085] 2. Prepare high-strength and high-ductility CuFe alloy, the chemical composition is designed as (wt.%): Fe=9.0%, Cu=91.0%. The composition of the prepared copper-iron alloy ingot is as shown in Table 2, the chemical composition of the ingot is stable, and the upper, middle and lower components of the ingot are uniform;

[0086] 3. The CuFe alloy ingot is processed into Ф0.06mm wire. After testing, the tensile strength of the Ф0.06mm wire is 443N / mm 2 ; The elongation rate is 12%; the copper-iron alloy also has excellent electromagnetic shielding effect.

Embodiment 3

[0088] 1. The process of preparing the copper-iron master alloy masterbatch in this embodiment is the same as in embodiment 1.

[0089] 2. Prepare high-strength and high-ductility CuFe alloy, the chemical composition is designed as (wt.%): Fe=9.5%, Cu=90.5%. The composition of the prepared copper-iron alloy ingot is as shown in Table 2, the chemical composition of the ingot is stable, and the upper, middle and lower components of the ingot are uniform;

[0090] 3. The CuFe alloy ingot is processed into Ф0.06mm wire. After testing, the tensile strength of the Ф0.06mm wire is 445N / mm 2; The elongation rate is 11.2%; the copper-iron alloy also has excellent electromagnetic shielding effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com