Anti-scouring and anti-corrosion high-pressure throttling valve and producing method of combined valve element

A high-pressure throttling and anti-corrosion technology, applied in the direction of lift valves, valve devices, engine components, etc., can solve the problems of increasing the production cost of high-pressure throttle valves, the waste of carbide alloy materials, and the difficulty of users to accept the use, so as to improve the durability Erosion anti-corrosion performance, reduce production and operation costs, prolong the effect of working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

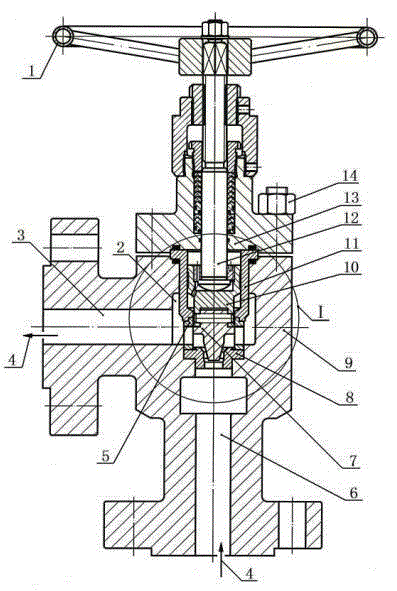

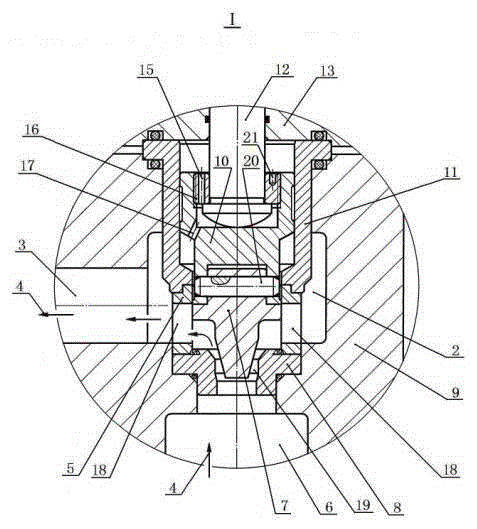

[0037] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

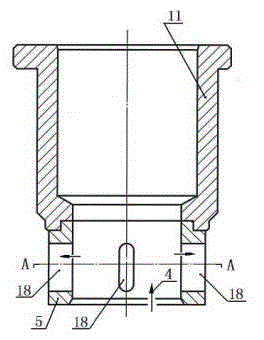

[0038] The invention proposes a erosion-resistant and corrosion-resistant high-pressure throttle valve, which is mainly composed of a valve body 9, a valve cover 13, a valve seat 8 fitted in the valve cavity 2, a combined sleeve, a combined valve core, connected to The valve stem 12 of the combined valve core and the adjusting handwheel 1 installed on the top of the valve stem 12 are composed of the combined sleeve. The bottom of the upper cylinder 11 is provided with a concave ring groove 22, and the top surface of the throttle sleeve 5 is provided with a convex ring 23 matching the concave ring groove 22, and the convex ring 23 of the throttle sleeve 5 is tightly fitted. In the concave ring groove 22 of the upper cylinder body 11, the integral connection structure of the combined sleeve is formed. The combined spool is composed of an upper core body 10, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com