A preparation method of porous heat transfer surface with local controllable hydrophilicity and hydrophobicity

A heat transfer surface, hydrophilic technology, applied in the field of heat transfer enhancement, can solve the problems of heat exchanger burning, heat transfer surface dry burning, heat transfer efficiency reduction, etc., to improve heat flow density, reduce superheat, and promote perfection and developmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

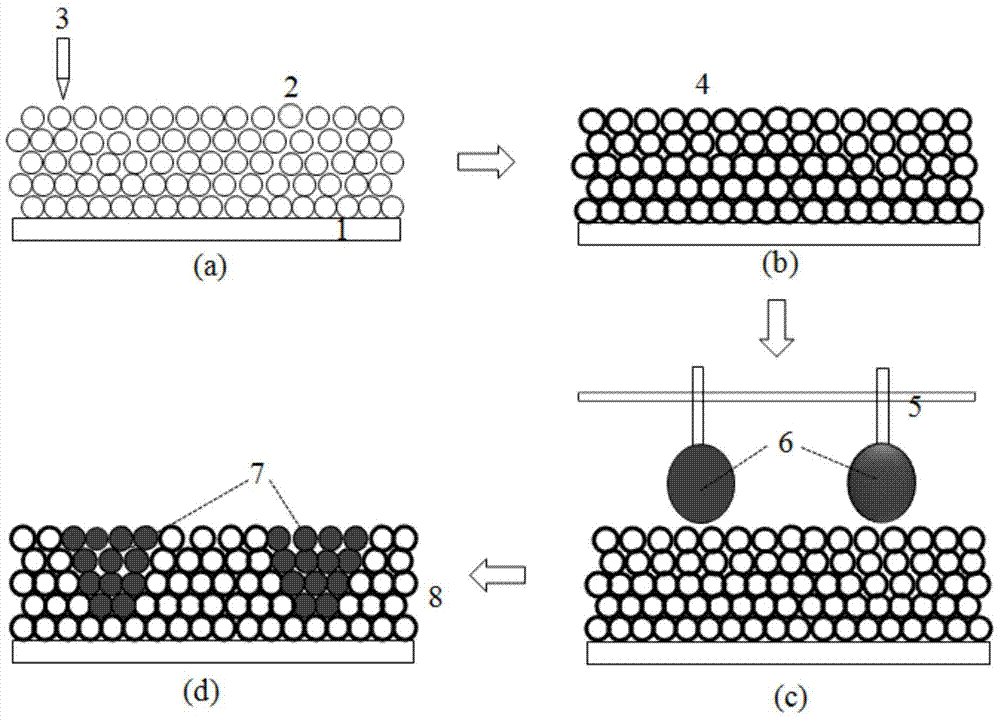

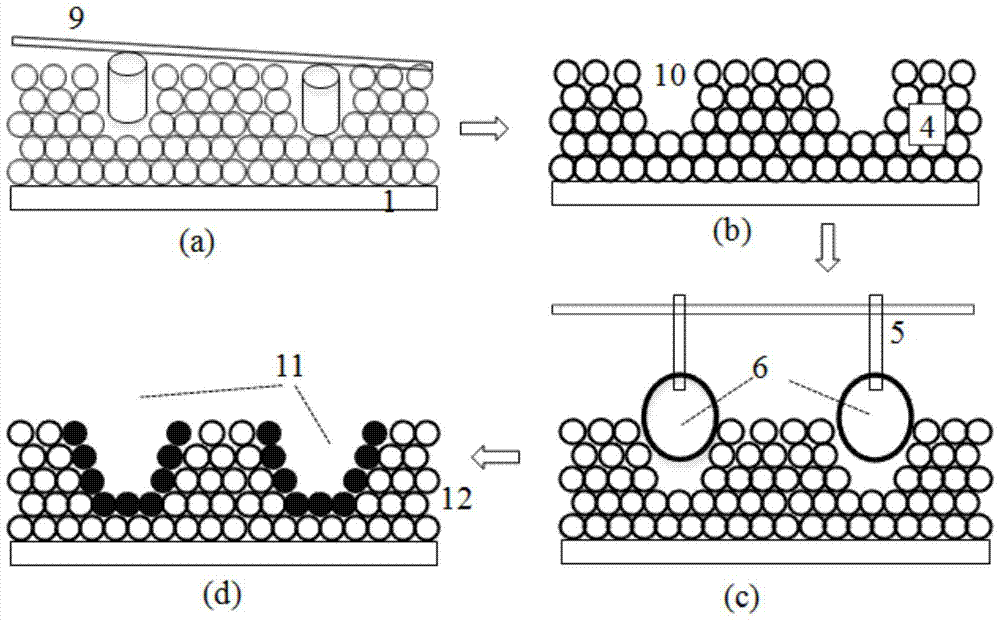

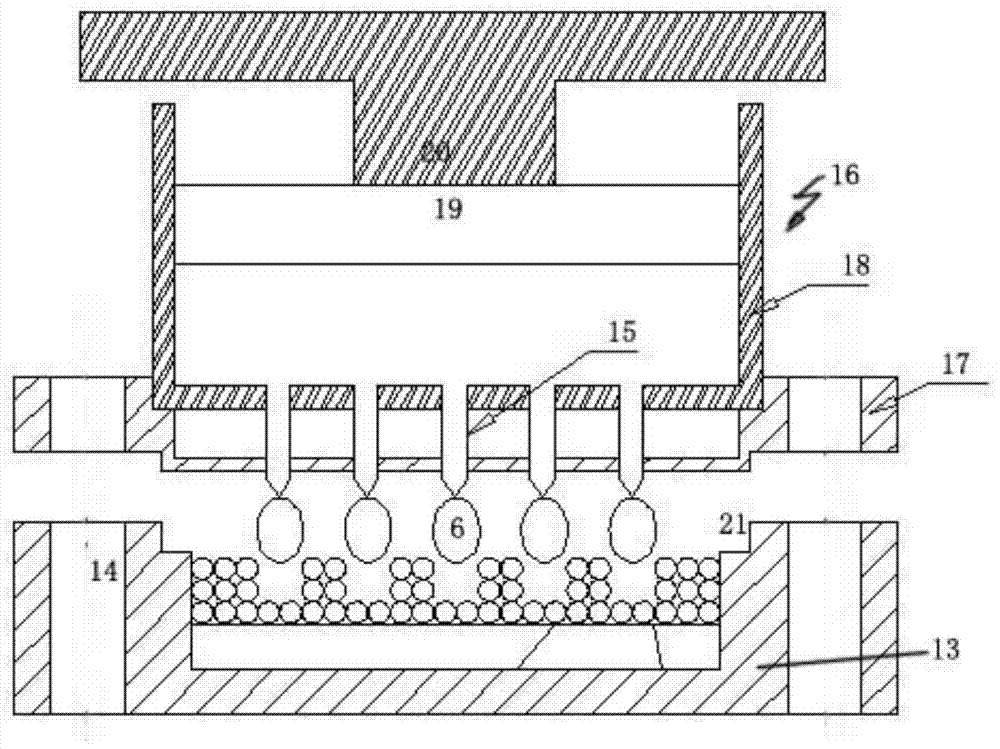

Method used

Image

Examples

Embodiment 1

[0043] Sintered porous metal surface: choose copper metal as the heat transfer metal base surface material 30mm×40mm, firstly perform ultrasonic surface cleaning treatment; choose metal Cu / CuO micron particles with a scale of 600nm‐1μm with good heat transfer performance; use plastic scraper Spread the metal particles on the surface of the substrate with a thickness of 120 microns. Fix the heat-exchanging metal base surface in the positioning groove; under the protection of nitrogen, sinter at 600-700 ° C for 3 hours, and then cool naturally under the protection of nitrogen; obtain a porous metal heat transfer surface.

[0044] Hydrophilic treatment of porous metal heat transfer surface: First, ultrasonically clean the porous metal heat transfer surface (porous metal structure) with acetone for 20 minutes, then wash with alcohol, isopropanol, and deionized water in sequence, and use 2.0M hydrochloric acid to remove the oxide film. Wash with deionized water, dry in nitrogen; th...

Embodiment 2

[0047] Sintered porous metal surface: choose copper metal as the heat transfer metal base surface material 30mm×40mm, firstly perform ultrasonic surface cleaning treatment; choose metal Cu / CuO micron particles with a scale of 10‐35μm with good heat transfer performance; use plastic scraper Spread the metal particles on the surface of the substrate with a thickness of 100-200 microns. Fix the heat-exchanging metal base surface in the positioning groove; under the protection of nitrogen, sinter at 600-700 ° C for 3 hours, and then cool naturally under the protection of nitrogen; obtain a porous metal heat transfer surface.

[0048] Hydrophilic treatment of porous metal heat transfer surface: First, ultrasonically clean the porous metal heat transfer surface (porous metal structure) with acetone for 20 minutes, then wash with alcohol, isopropanol, and deionized water in sequence, and use 2.0M hydrochloric acid to remove the oxide film. Wash with deionized water, dry in nitrogen; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com