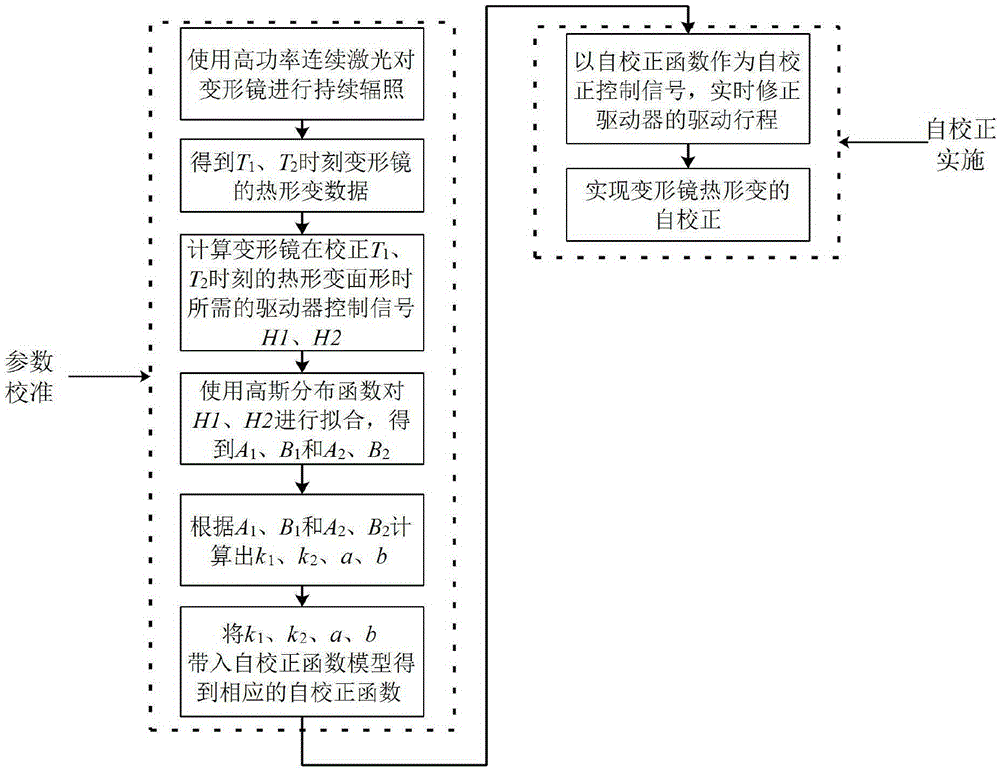

Self-calibration method for thermal deformation of distorting lens under effect of high-power continuous laser irradiation

A technology of laser irradiation and deformable mirror, applied in the field of strong laser technology and adaptive optics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0076] The deformable mirror used in this embodiment is a discrete drive type deformable mirror, and its structure is as follows Figure 4 Shown in middle (a); include the film 8 on the surface of the deformable mirror, the mirror surface 9, the pole head 10, the driver 11 and the base 12; its film film structure is: Sub / (HL) 11 H / Air, where Sub means silicon substrate, H means ZnS film, L means YbF 3 thin film, at a central wavelength λ 0 =3.8 μm under normal laser incidence conditions, the film system absorption rate is 109ppm; the diameter of the deformable mirror mirror surface 9 is 180mm, the thickness is 2.5mm, and the material is single crystal silicon; the deformable mirror pole head 10 is a driver 11 The connection unit between the mirror surface 9 is made of monocrystalline silicon, and the diameter of a single pole head is 8 mm, and the length is 10 mm; the driver 11 is the main device for controlling the shape of the deformed mirror surface, and its material is pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com