Material with schemochrome and capable of being induced to change color through stress and preparation method of material

A structural color and stress technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as harsh conditions, long time consumption, and high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

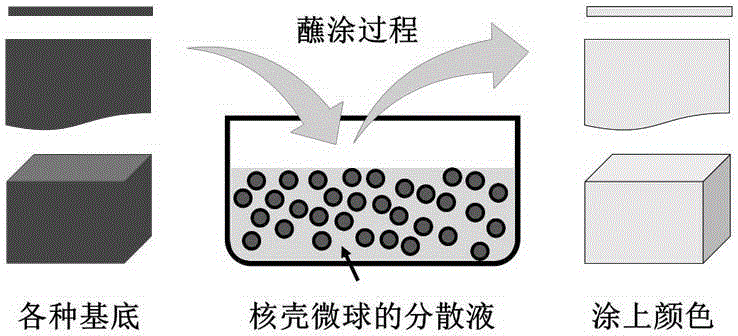

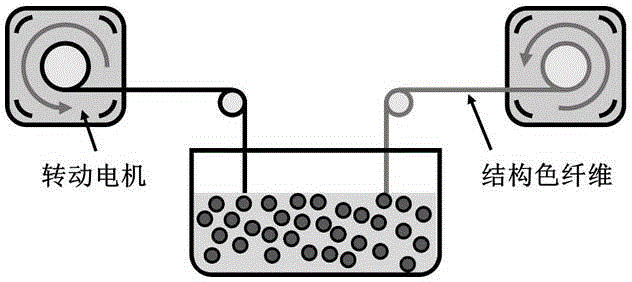

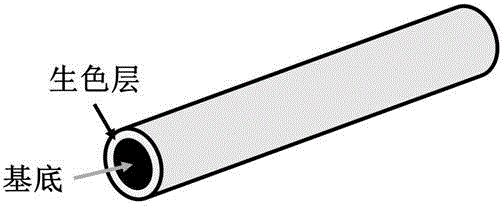

Method used

Image

Examples

Embodiment 1

[0025] (1) Preparation of core-shell polymer microsphere dispersion

[0026] Under an inert atmosphere, add a pre-emulsion containing 0.18g sodium lauryl sulfate, 0.4g 1,4-butanediol diacrylate, 3.6g styrene, and 217g deoxygenated water to a 1L flask. rise to 75°C. Gradually add 50mg sodium bisulfite, 350mg sodium persulfate, 50mg sodium bisulfite to initiate the reaction. Then, the prepared pre-emulsion of 6.6g of 1,4-butanediol diacrylate, 59.4g of styrene, 0.3g of sodium lauryl sulfate, 0.1g of potassium hydroxide and 90g of deoxygenated water was slowly added dropwise. After it dripped off, 100 mg of sodium persulfate was added. After 10 minutes, a uniformly dispersed pre-emulsion of 3.0 g allyl methacrylate, 27.0 g methyl methacrylate, 0.15 g sodium lauryl sulfate and 40 g deoxygenated water was slowly added dropwise. After it has been completely dripped, slowly add a uniformly dispersed pre-emulsion of 130g of ethyl acrylate, 0.33g of sodium lauryl sulfate and 139g of...

Embodiment 2

[0030] (1) Preparation of core-shell polymer microsphere dispersion

[0031]Under an inert atmosphere, add a pre-emulsion containing 25 mg of sodium lauryl sulfate, 0.1 g of 1,4-butanediol diacrylate, 0.9 g of styrene, and 54 g of deoxygenated water into a 250 mL flask, and gradually raise the temperature under vigorous stirring. to 75°C. Gradually add 12.5 mg sodium bisulfite, 87.5 mg sodium persulfate, 12.5 mg sodium bisulfite to initiate the reaction. Then, the prepared pre-emulsion of 1.65g of 1,4-butanediol diacrylate, 14.85g of styrene, 75mg of sodium lauryl sulfate, 25mg of potassium hydroxide and 22.5g of deoxygenated water was slowly added dropwise. After it dripped off, 25 mg of sodium persulfate was added. After 10 minutes, a uniformly dispersed pre-emulsion of 0.75 g of allyl methacrylate, 6.75 g of methyl methacrylate, 37.5 mg of sodium lauryl sulfate and 10 g of deoxygenated water was slowly added dropwise. After it has been completely dripped, slowly add a un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com