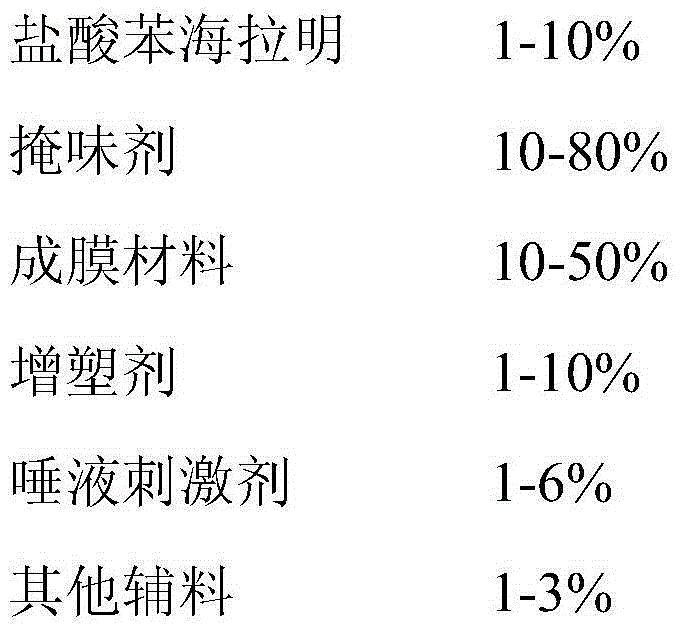

Preparation method of diphenhydramine hydrochloride oral instant film agent

A technology of diphenhydramine hydrochloride and oral instant film, which is applied in the direction of medical preparations with non-active ingredients, medical preparations containing active ingredients, and pharmaceutical formulas, and can solve the difficulty of diphenhydramine hydrochloride in taste-masking, process Complicated and uncontrollable conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

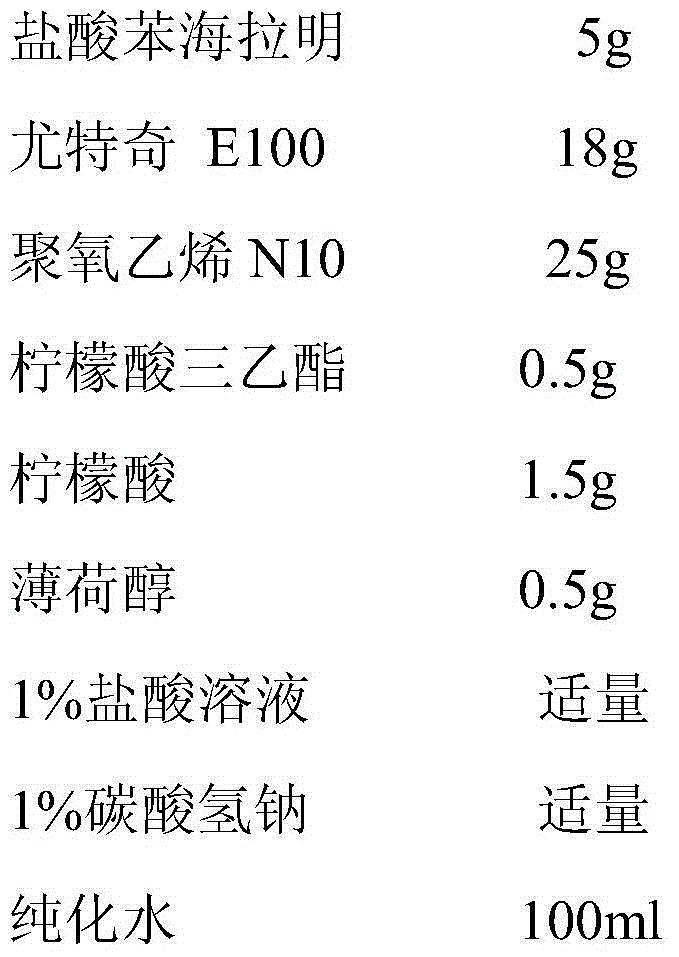

Embodiment 1

[0017]

[0018] Weigh the prescription amount of Eudragit E100 into 100ml water, adjust the pH 4-5 with 1% hydrochloric acid solution, add diphenhydramine hydrochloride and polyoxyethylene N10 and stir evenly, adjust the pH 6-7 with 5% sodium bicarbonate solution, To obtain a polymer gel, add the prescribed amount of triethyl citrate, citric acid, and menthol, shear at high speed (10000rpm) for 3 minutes, repeat 3 times, and let stand for 8h under vacuum to remove air bubbles. You have to scrape the gel. Scrape the glue on a stainless steel plate with a film coater, and dry it at a temperature between 50°C and 60°C. Then the film agent obtained by knife coating is peeled from the plastic film, and the film agent can be obtained by cutting and packing.

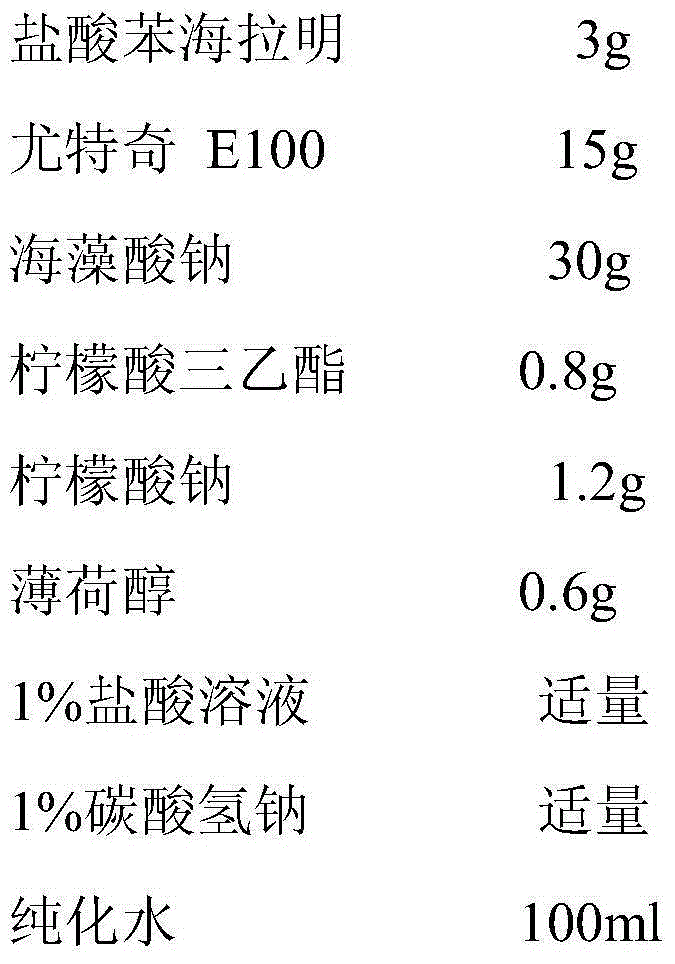

Embodiment 2

[0020]

[0021] Weigh the prescribed amount of Eudragit E100 into 100ml of water, adjust pH 4-5 with 1% hydrochloric acid solution, add diphenhydramine hydrochloride and sodium alginate and stir evenly, adjust pH 6-7 with 5% sodium bicarbonate solution to get Polymer gel, add prescription amount of triethyl citrate, sodium citrate, menthol, shear at high speed (10000rpm) for 3 minutes, repeat 3 times, let stand for 8h under vacuum condition to remove air bubbles, namely You have to scrape the gel. Scrape the glue on a stainless steel plate with a film coater, and dry it at a temperature between 50°C and 60°C. Then the film agent obtained by knife coating is peeled from the plastic film, and the film agent can be obtained by cutting and packing.

Embodiment 3

[0023]

[0024]

[0025] Weigh the prescription amount of Eudragit EPO into 100ml of water, adjust the pH 4-5 with 1% hydrochloric acid solution, add diphenhydramine hydrochloride and hypromellose and stir well, adjust the pH 6 with 5% sodium bicarbonate solution 7. Obtain polymer gel, add prescription amount of glycerin, sodium citrate, menthamide, shear at high speed (10000rpm) for 3 minutes, repeat 3 times, and let stand for 8h under vacuum condition to remove air bubbles. Gel for scraping. Scrape the glue on a stainless steel plate with a film coater, and dry it at a temperature between 50°C and 60°C. Then the film agent obtained by knife coating is peeled from the plastic film, and the film agent can be obtained by cutting and packing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com