Extrusion forming device and process for small-caliber chalcogenide glass bar material

A bar extrusion, chalcogenide glass technology, applied in glass forming, glass pressing, glass production and other directions, can solve the problems of low yield, large material loss, low material utilization, etc., to improve the yield, The effect of reducing manufacturing cost and saving material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

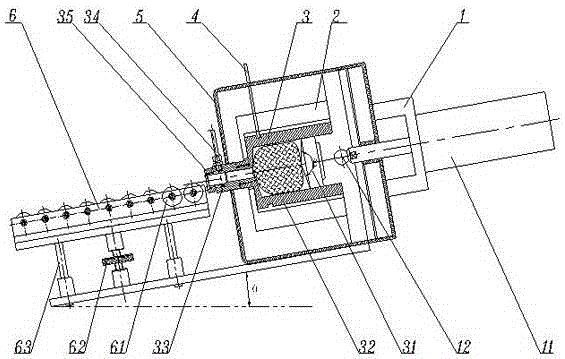

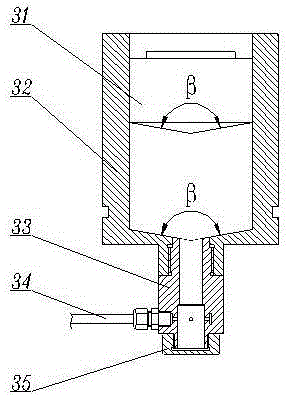

[0021] Such as figure 1 , figure 2 shown. The chalcogenide glass small-diameter rod extrusion molding device of the present invention comprises an extrusion mechanism 1, a heating furnace, a mold 3, a supporting wheel mechanism 6 and a flat plate. Wherein, heating furnace is made of outer cover 5, insulating layer, heating mantle 2 and furnace door, and heating mantle 2 is positioned at outer cover 5 center, and insulating layer is between outer cover 5 and heating mantle 2, and furnace door is located at the upper port of outer cover 5. The side of the heating furnace is fixed on one end of the flat plate, and the furnace door faces outwards. The supporting wheel mechanism 6 includes a V-shaped supporting wheel group 61 and a bracket. The bracket is composed of an adjusting screw 62 and a guide rod 63. The V-shaped supporting wheel group 61 adjusts its center height through the adjusting screw 62 and the guiding rod 63 to meet the needs of different caliber bars. Lifting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com