Resin composition

A technology of resin composition and compound, applied in the direction of circuit substrate materials, printed circuit parts, etc., can solve the problems of crack circuit and deformation of insulating layer and conductor layer, and achieve the effect of excellent peel strength and excellent surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

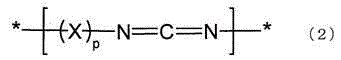

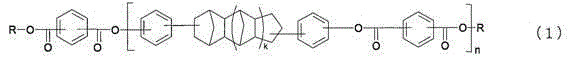

Method used

Image

Examples

preparation example Construction

[0136] The preparation method of the resin composition of this invention is not specifically limited, For example, the method of adding a solvent etc. to a compounding component as needed, and using a rotary mixer etc. to mix and disperse etc. are mentioned.

[0137] The resin composition of the present invention can obtain a cured product (insulating layer) with a low dielectric loss factor. The dielectric loss factor of the cured product of the resin composition of the present invention can be measured by the method described in described later. Specifically, it can be measured by the cavity resonator perturbation method under conditions of a frequency of 5.8 GHz and a measurement temperature of 23°C. From the standpoint of preventing heat generation at high frequencies, reducing signal delay and signal noise, the dielectric loss factor is preferably 0.010 or less, more preferably 0.009 or less, further preferably 0.008 or less, 0.007 or less, or 0.006 or less. The lower l...

Embodiment

[0188] Hereinafter, although an Example demonstrates this invention concretely, this invention is not limited to these Examples. In addition, "part" means a mass part.

[0189] 〔Measurement method, evaluation method〕

[0190] First, various measurement methods and evaluation methods will be described.

[0191]

[0192] (1) Substrate treatment of inner layer circuit board

[0193] Both sides of a glass cloth base epoxy resin double-sided copper-clad laminate (thickness of copper foil: 18 μm, thickness of substrate: 0.4 mm, “R1515A” manufactured by Panasonic Co., Ltd.) on which inner layer circuits are formed are used "CZ8101" manufactured by MEC Co., Ltd. etched 1 micrometer, and roughened the copper surface.

[0194] (2) Lamination of adhesive films

[0195]The adhesive films prepared in Examples and Comparative Examples were bonded to the inner layer circuit board with the resin composition layer using a batch-type vacuum pressure laminator (“MVLP-500” manufactured by M...

Embodiment 2

[0217] Except that the compounding amount of the carbodiimide compound ("V-03" manufactured by Nisshinbo Chemical Co., Ltd., a toluene solution with 50% by mass of non-volatile content) was changed to 80 parts, the resin varnish was produced in the same manner as in Example 1. Adhesive film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com